Project Gallery: Magnolia Pavilion

This timber-frame pool pavilion has its own guest entry and distinct areas for cooking, dining, and relaxing.

Designed by architect Tony F. Miller for homeowners in North Carolina, this timber-frame pool pavilion has its own guest entry and distinct areas for cooking, dining, and relaxing. The dining rotunda has a built-in pizza oven and a custom-designed table to accommodate eight to 16 people. The center section of the structure features the kitchen and bar. The lounge rotunda provides a covered seating area located adjacent to the fireplace.

Along with his associate James Nevada, Miller modeled the pavilion in SketchUp, the same program that was used by the timber-framing firm Carolina Timberworks. Before the construction process began, the two firms exchanged their Sketch-Up files. This allowed each firm to contribute technical and design information at all stages of the project and enabled the clients to review each step.

Western red cedar from British Columbia was used for the timber-framing, connected by hand-cut traditional pegged mortises and tenons. Timber surfaces were sanded, and the edges were eased with a draw knife. The pavilion’s ceiling has a floral motif that mimics a magnolia tree near the pool slide. The inner ceiling of the pavilion has no ledges or horizontal surfaces for birds to roost or for pollen to collect.

The homeowners preferred the durability of Pennsylvania bluestone for the pool deck. Bluestone’s dark color and density normally make it too hot to walk on in bare feet. The homeowners and their general contractor consulted with a hydraulic engineer and the underlayment company, Schlüter Systems, to design a sophisticated cooling system under the stone. To maximize the system’s efficiency, the stones were cut thinner than usual. Sloped to drain water, they dry almost immediately after a rain. For more photos of the pavilion, go to Project Gallery Extra.

Design: Tony F. Miller, AIA LEED AP, Miller Architecture, Charlotte, N.C., millerarchitecture.com

General contractor: Ed Tennent, Charlotte, N.C., kellymcardle.com

Timber-frame contractor: Carolina Timberworks, Boone, N.C., carolinatimberworks.com

Timber-frame engineer: D. Remy & Co., Hayesville, N.C., dremy.com

Finish photographs: Tim Buchman, timbuchman.com, courtesy of Miller Architecture

Process photograph and illustration: courtesy of Carolina Timberworks A warm spot. The large firebox with a shallow Rumford-style backing projects heat outward.

A warm spot. The large firebox with a shallow Rumford-style backing projects heat outward.

The timber framer’s tale

by James Heaton, lead craftsman, Carolina Timberworks

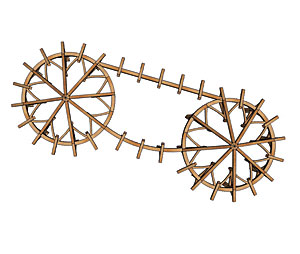

The first time I saw the project, it was on the computer screens of our designers, Craig Kitson and Chris Miller. Even though the drawings were not complete, I immediately told them I wanted to build it. I knew these clients liked challenging curves. We had already built them a timber-frame trellis, which involved a large ellipse designed to mirror a radial window above the trellis. The architect called for an impressive level of detail in the pavilion. Structurally, the round sections are built in an octagonal hammer-beam configuration with octagonal finials on the end of each hammer post, all braced back to the radial top plate by braces that have segmental arches cut in them. It was as complicated as it sounds. Prefitting in our shop made for a great show for visiting clients. Because our shop wasn’t big enough for the whole structure, we had to fit it in sections, sometimes right side up, sometimes upside down. It was always a bit of a spectacle, and as word got around town, a lot of visitors came to the shop and took lots of photos.

We try to ship timber frames in assembled sections whenever possible. We also try hard to disturb the building site as little as possible. In this case, we wound up weaving through the pines surrounding the adjacent golf course with giant arches dangling from the forks of an all-terrain-type forklift. I am certain that golf scores suffered that day.

It’s a joy to work with people passionate about design and quality construction. In the final assessment, my hat is off to the architect, the contractor, and of course, the homeowners.

See more beautiful photos of the Magnolia Pavilion in our Project Gallery Extra

Drawing board. Preliminary renderings of the pavilion were created in SketchUp.

Drawing board. Preliminary renderings of the pavilion were created in SketchUp.  Getting underway. Some prefitting work was done with the structure upside down, which made working on the rotunda of this building more comfortable.

Getting underway. Some prefitting work was done with the structure upside down, which made working on the rotunda of this building more comfortable.