Prep Doors for Knobs and Dead Bolts

Get the hole layout right, and the rest of the job is straightforward.

Boring and mortising a door for a knob or lock is not a hard job, but if you get the holes in the wrong spot, you’re in for a tough fix. You might even have to buy a new door. Fortunately, it’s easy to get the holes right if you pay attention to two critical dimensions and use the paper layout template that comes with the door.

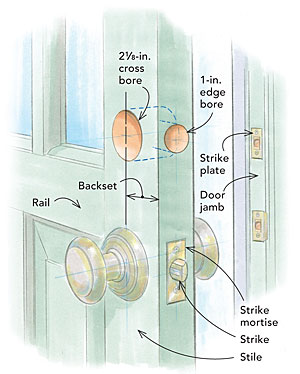

You need a 2-1⁄8-in. hole saw and a 1-in. spade bit for making the holes. A few dead bolts need a 1-1⁄2-in. hole saw instead of a 2-1⁄8-in. hole saw, though, so check the instructions to make sure you have the right one.

The first critical dimension you need to know is the door thickness. Exterior doors are generally 1-3⁄4-in. thick. Most interior doors are 1-3⁄8-in. thick. When it’s time to mark the door for boring, choose the mark on the template that corresponds to the door thickness. If the door is thinner than 1-3⁄8-in. or thicker than 1-3⁄4-in., you’ll likely need a special-order lock.

The second critical dimension is backset, which is the distance the center of the knob or dead bolt is from the edge of the door. Doors almost always have either a 2-3⁄8-in. or 2-3⁄4-in. backset, and most modern locksets and dead bolts accommodate both. If you’re adding a dead bolt, match the backset of the existing doorknob; if you’re starting with a new door, choose the backset based on the door. Generally, 2-3⁄4 in. is the preferred backset because it leaves more room for your knuckles when you’re closing the door. However, narrow doors (less than 32-in.) and doors with narrow stiles, such as many full-glass doors, often look better with a 2-3⁄8-in. backset because it brings the knob closer to the center of the stile.

Most doorknobs are installed between 32-in. and 36-in. above the floor; dead bolts are about 44-in. above the floor. However, you may have to adjust these dimensions slightly to match other doors or to avoid interfering with screen-door hardware.

Once you’ve drilled the door, mark the mortises with a sharp utility knife. I like to screw the strike and strike plate in place temporarily and then scribe around them. The knife groove makes it easier to locate the chisel accurately. Make sure your chisel is sharp, and work from the top and bottom toward the hole in the center to prevent slipping past the outline of the mortise. Finally, be sure to use the 3-in.-long screws that come with the dead bolts, because they provide much greater resistance to forceable entry than do shorter screws.

Step by Step

Tools for preparing doors

You can find cheaper hole saws than the ones shown below, but it’s worth spending a few extra dollars for pro-quality saws with bi-metal construction, which stay sharp longer than standard saws.

Web Extra: How To Install an Exterior Doorknob in a New Door

Photos and Illustration: Dan Thornton