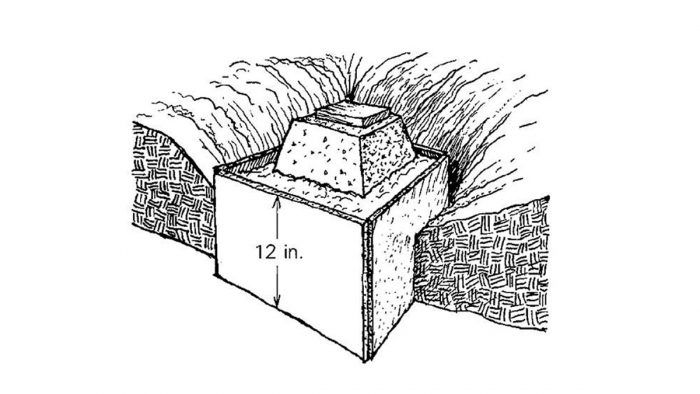

We recently did a foundation job in very crumbly, sandy soil. The first task was to set 27 pier blocks in pier holes that were 18 in, on a side and 12 in. deep. But by the time we had dug down a foot, we often had a hole that was more than 2 ft. across at the top and growing. Faced with filling these craters with concrete, we calculated that we would waste more than a cubic yard.

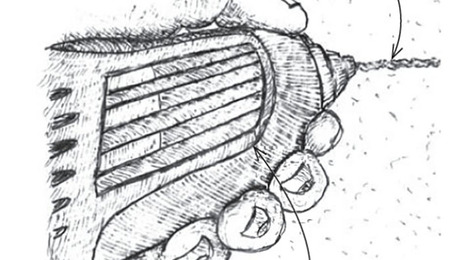

Instead of ordering the extra concrete, we transformed four sheets of gypboard into form boxes. We cut the sheets into 6-ft. lengths, and scored them along their length at 18 in. o.c., leaving the face paper intact. Perpendicular to these scored lines, we cut the board into 12-in. wide strips. These strips were then folded into square boxes, placed in the oversized holes and backfilled. The forms not only saved concrete, but also gave us an accurate way to calculate our ready-mix order.

—Sunrise Builders, Santa Cruz, CA

Edited and illustrated by Charles Miller

From Fine Homebuilding #13

View Comments

Great idea!! Do these forms then just stay in the ground or do you pull them out after the concrete sets up?

The great thing about using drywall for forms is I can leave the form materials in the dirt if I need to.