I’ve seen a lot of different ways to make built-up headers on job sites here in Wyoming — from the traditional to the bizarre. The traditional method is to sandwich 1/2-in. plywood between 2x material until you get the desired thickness to match the depth of the wall studs. Unfortunately, this causes two problems. First, wood never behaves the way it should, and by the time the header is finished, it isn’t the same thickness as the wall. For a 2×6 wall, for example, the header often ends up at 5-5/8 in. or thicker, if the material is cupped or twisted. When trim time rolls around, you have unhappy carpenters. Second, this kind of header has no insulative value.

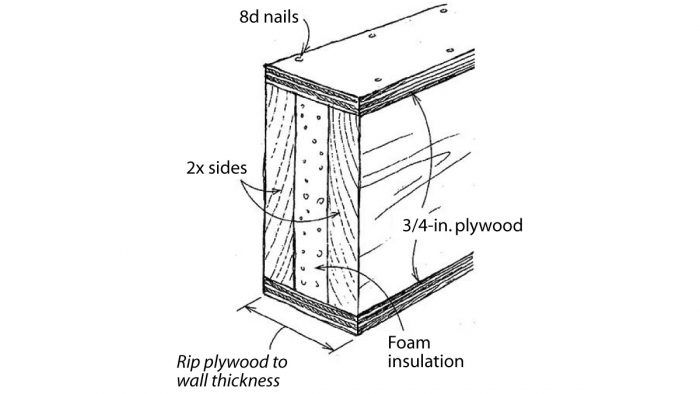

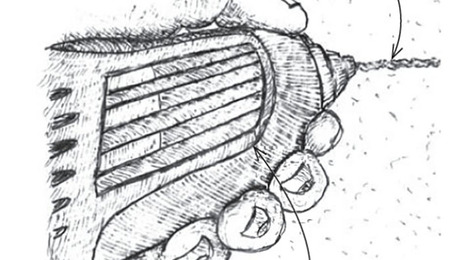

The drawing shows the header that I’ve been assembling to solve both of these problems. It’s essentially a box beam with plywood tops and bottoms, and sides made out of either 2x or, my favorite, laminated lumber. The result is a header precisely the same dimension as the wall and a continuous void the length of the header for insulation.

My engineer had no problems with the structural capability of this design. The key is to provide adequate nailing through the plywood into the sides. For these headers, I used 8d nails spaced on the same centers as the perimeter nails in our plywood wall sheathing. The results were the absolutely most perfect, easiest-to-work-with headers I have ever seen.

—Bill Welch, Jackson, WY

Edited and Illustrated by Charles Miller

From Fine Homebuilding #115

View Comments

Why not reverse the plywood & lumber and construct an APA box beam?

Use vertical 3/4" Struct I plywood faces with ripped 2x top & bottom chords. Install blocks for glue & fasteners at plywood joints.

This adds another 1-1/2" of insulation & saves the cost of laminated lumber (although the plywood will cost a bit more).

The fastest an easiest way is to sandwich and nail together the headers without any plywood or insulation. Just nail the header flush to the outside of the wall and let the insulator install the insulation on the inside. With a 2-ply header in a 2x6 wall, you'll have 3" thickness of insulation.

@ CT_Yankee, It is not possible to construct a bearing header in the way you describe for an outside bearing wall. You do realize this is a bearing header. The insulation in the diagram is a dead giveaway. Plywood would never be of sufficient in strength or up to code would this fly in a vertical position on an outside bearing point.

It is apparent to me that you do not understand the principles of a plywood box beam.

Couldn't resist commenting even though tis thread is almost ancient.

This tip was first posted in 1998.

nailbender, are you seeing the sketch correctly? The plywood is used to close off the top & bottom of the header. The 2x's are used to bear the roof (tension) load. The plywood only sees a compressive load. Providing the 2x's meet the load specs in the engineering table, all is well. Filling the void with insulation, instead of wood is an old, therefore proven, practice.

@nailbender123,

Why do you say a box beam header can't be used on an outside bearing wall? The APA has a spec sheet for what size header can be used for what specs, see their data file "Nailed Structural-Use Panel and Lumber Beams"

Gotta wonder why someone isn't making a pre-fab version, kind of like SIPs or TJs and I-Joists, half a dozen configurations for various span & load ratings, buy them by the foot, square, straight, stiff, strong, certified. As b_ward points out, it's been 22 years since the idea was first posted.