When I’m working in my shop, I always have the benefit of a large cabinet saw with an equally large extension table and outfeed table to support large panels or long boards. But after starting my home-remodeling business, I needed a way to make my bench-top saw just as versatile when I’m working in somebody’s driveway.

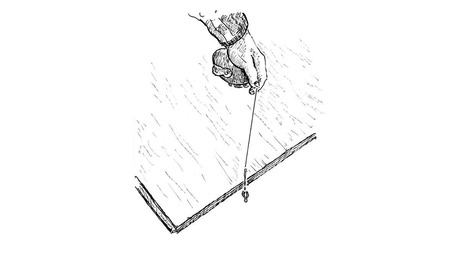

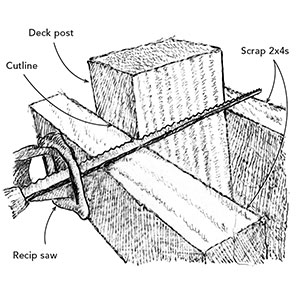

As shown in the drawing, I solved the problem with a $19 folding table that can be set up as either an extension table or as an outfeed table. I brought the table up to the correct height with adjustable leg extensions. The extensions are hollow and slide onto the table’s legs, where they bear against the crossbars. I made the extensions of scrap 1/2-in. plywood, 3-1/2-in. by 1/2-in. carriage bolts, and four hockey pucks, which came to a total of $5.52.

I drilled the hockey pucks to accept the carriage bolts. The bolt heads are countersunk into the bottoms of the pucks, and each bolt is tightened with a nut and some Loctite adhesive.

The hockey-puck feet thread into hardwood blocks glued into the bottom of each leg. I cut the threads for the bolts directly into the hardwood, reasoning that the threads likely will hold up longer than the table. So far, that has proved to be true. The table is holding up well, and its slick surface is an added benefit.

Dan Broadbelt, via email, None

View Comments

This sounds perfect for what I need. However, there is no drawing shown. Can you send me the drawing or post it online? Thank you.