When I am hanging doors or adjusting doors, the strike plate occasionally isn’t ideally located, causing the door latch to have play at the strike or, if too tight, making it difficult to latch without slamming or pushing hard.

Some carpenters remove the strike plate, plug the screw holes with small-diameter dowels (matchsticks are a time-honored plug), and then drill new holes for the strike-plate screws.

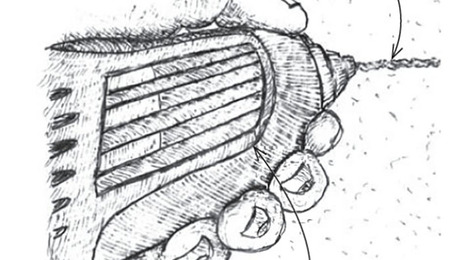

As a longtime professional residential carpenter, I’ve used another method that is a lot simpler and works just as well. First, I determine which way the plate has to be moved, either toward the jamb-stop molding or away from it. I remove the strike, I put a 5d finish nail in my drill, and I create a new screw hole to the side of the existing one in the direction I want to move the strike plate. I use a nail because it doesn’t drill a new hole but instead separates the wood fiber, essentially moving the screw hole to one side or the other. I then reinstall the strike plate, and the screws hold as if it were a new hole.

If a 5d nail isn’t available, use a 4d. The smaller-gauge nail works better than the next size up.

Ron Gay, Pontiac, MI