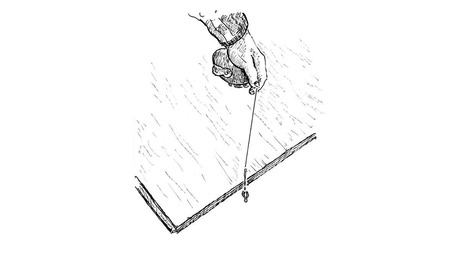

While casing windows with some fancy trim, I had problems keeping the stock from being pulled into the blade. I was cutting prefinished hemlock casings at a 45° angle for picture-frame joints. Even though the 80-tooth carbide blade was sharp, it still pulled the stock inward, leaving the cuts a bit irregular.

To remedy the problem, I used contact cement to glue 120-grit wet/dry sandpaper to the bed of my power miter saw — one piece on either side of the blade. It worked very well. The friction of the sandpaper was just enough to hold the casings fast as I made my cuts.

Jim Esser, Bellingham, WA