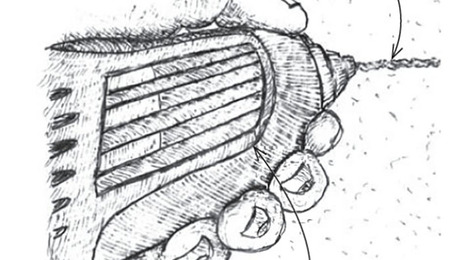

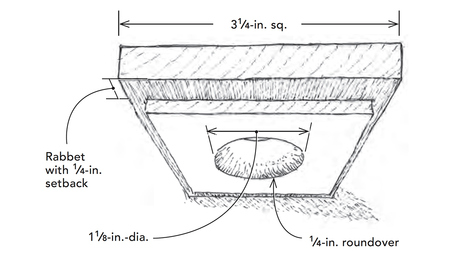

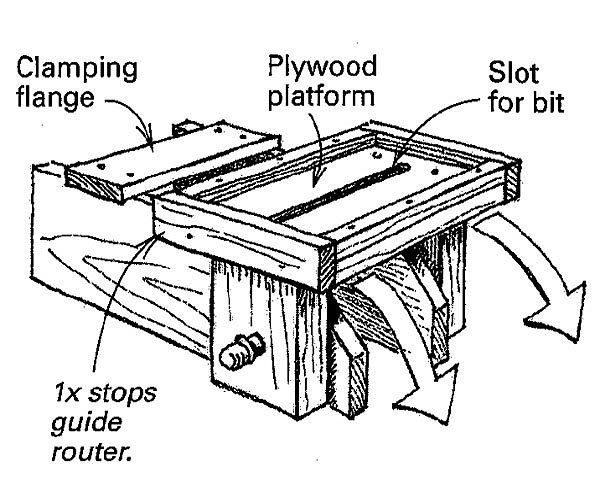

Cutting a profile in the exposed ends of rafters and beams is a nice custom touch, but it can also be tedious and time-consuming. When a job came up cutting about 100 decorative beam ends for an Austrian farmhouse-style building, I had the motivation to come up with an efficient method. Instead of mounting a bandsaw on casters or buying a portable bandsaw, I developed a jig for my router. As shown in the drawing, the jig consists of two parts joinedby a pair of axles. The movable portion is a plywood platform the width of my router base. The platform is bordered by 1x stops, which limit the movement of the router. A slot down the platform’s center allows the bit to extend downward into the workpiece — a beam in this case. The router platform pivots on a wooden housing made of 1x8s.

To use the rig, I first cut off most of the waste material on the end of the beam with a circular saw so that the jig will rotate. Then I clamp the housing to the beam and plunge the router into the work using a 1/2-in. spiral bit. It takes two passes with the router working back and forth on the platform and up and down through its arc to make the rough cut. Another minute or so working with a sanding block removes the fuzzy edges.

Robert S. Smith, Leavenworth, WA