I’m building an apartment in a commercial building that dates back to 1851. To remain true to the original detailing, the casings around doors and windows needed rosettes at the corners. So I checked out a rosette router bit and choked on the $50 price tag.

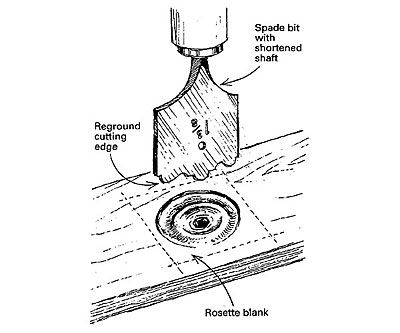

Back in my shop, I played around with a 1-3/8-in. spade bit and a tabletop grinder. First I rounded the bit’s shoulders, which correspond to the outside ring of the rosette. Then, halfway between the point and the shoulders, I ground in the cove shapes. Next, I flattened the bit’s point to carve the rounded hollow at the center of the rosette. My last modification was to cut off most of the bit’s shaft to reduce the chance that the bit would wobble in the drill press.

I chucked the bit (see drawing) in my drill press and made a couple of test cuts to check the profile. After some minor modifications, the bit was ready to go to work. Since then I’ve used the bit in oak, teak and fir with great results. And all for the price of a spade bit.

James R. Chittick, Fort Mill, SC

Click the "thumbs up" button above to vote for this tip. Help us choose Fine Homebuilding's top-10 window and door tips.

View Comments

It looks too small to me to be used on any door or window trim.