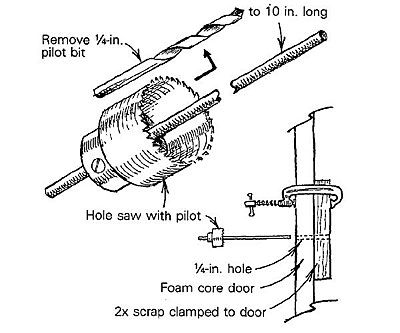

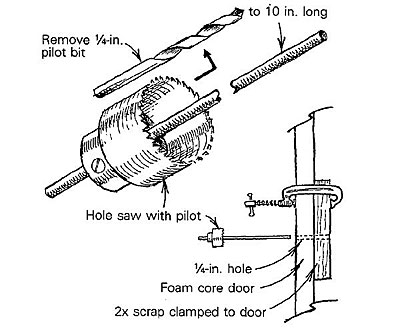

I had to drill holes for deadbolt locks in some steel doors that had foam cores, and I almost destroyed the first couple of doors using a standard hole saw because the 1/4-in. pilot bit would wander off course in the soft foam. To remedy the situation, I removed the pilot bit and replaced it with a piece of 1/4-in. mild-steel rod, as shown in the drawing. To use the modified saw, I first drilled a 1/4-in. pilot hole through the door and a 2x block clamped to the door. Using the pilot hole to guide the steel rod, I cut my holes with no wobble and no tearout. Incidentally, for this work I found that a bi-metal hole saw held its edge better than one made of steel.

E. F. Bott, Jr., Troy, NY

Click the "thumbs up" button above to vote for this tip. Help us choose Fine Homebuilding's top-10 window and door tips.