If you need to drill a hole to install some bell wire, you could buy a special bit for it, and since you’re going to only use it once, then go and sell it on Ebay. But there’s a better way.

Other Video Tips

Make a Custom Holesaw to Remove Stripped Screws

Sam Yoder from Cambridge, Massachusetts, uses an insulation support wire for exactly this purpose. Here’s how he does it. The first thing to do is to put a chisel point on the end of it so it will go through wood, or drywall, or plywood, or whatever. Sam uses a pair of side cutters to cut the end of one of these wires on a bias so it forms a little chisel point. Make sure you wear your safety glasses when you’re doing that. This point is sharp enough to go through most building materials, and you can renew it with another snip of the side cutters whenever you need to. And incidentally, this is a great way to go through a subfloor assembly if you need to run a wire from up above to down below. And you can even use it as a snake by taping wires to it to pull them from one floor to the next.

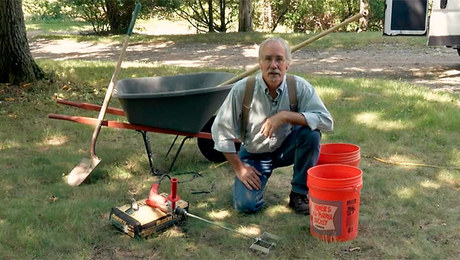

As a demonstration, I’m going to go through a 4×4 and see if I need to resharpen the homemade bit. Sam says he’s used this to go around corners in wood, and I’m going to take his word for that. How about that? Drilling a curved hole with one of these things. Thanks, Sam. Great tip.

View Comments

Chuck,

I’ve been drilling with insulation supports or the straight part of a wire coat hanger for more than 15 years. It is great for positioning and lining up to see exactly where you are before cutting or drilling bigger holes between floors, walls, or roofs etc. It leaves an extremely small hole to patch, if you even have to, if it is in the wrong place.

But I’m having trouble figuring out what kind of wire you could fit into a 1/16” hole. Or how you could tape wires to it and still fit back through the hole to use it as a snake.

Thanks for all the tips.

Mike Rowan

Belford, NJ

Dang small wire. Thanks for the tip!

I think you should get fine home building to do a review of your vest. This vest is my only solution for carrying my tools because im extremly skinny and have no waist to carry tool belts, they just slide off and dont go small enough.