Replacing a Wooden Girder with a Steel I-Beam

As level building lots continue to disappear, we’ll need to make the most of sites once thought unbuildable–and rely on technology to help us do it. This blog shows of the construction details of the in-law suite featured in last week’s posting, “An Award-Winning In-law Suite on an Unforgiving Site.”

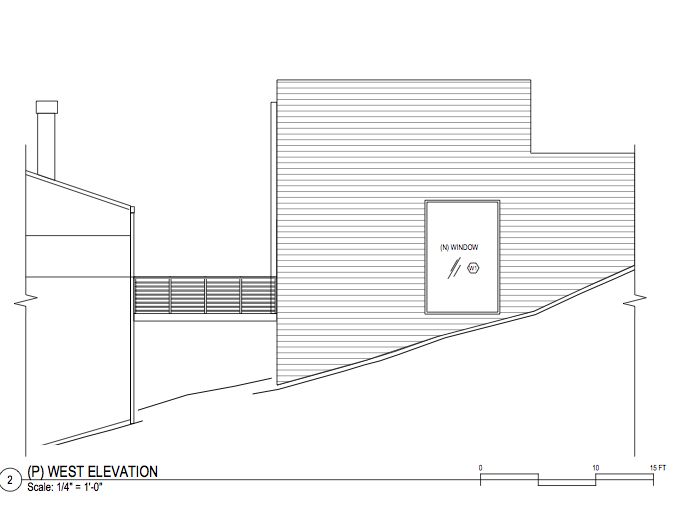

To recap, the garage structure was cut into a steep, south-facing slope above San Francisco. The lot’s high side bordered a city street, so a garage right on the street became the portal to descending stairs, an elevated walkway, and a dramatic, modern house set downhill about 50 ft. from the road.

In time, the homeowner realized that the cavernous space under the garage could accommodate an in-law suite, so he hired Stephen Shoup, principal of buildingLab in Emeryville, Calif., to design and build it. The great challenge of the project involved transferring the loads borne by the main girder-which supported a garage floor above-to a steel I-beam set flush to the finished ceiling that would span the 22-ft. width of the suite without intervening support posts.

The weights were considerable. The garage floor system consisted of 2×12 douglas fir joists spaced 12 in. on center, a 3/4-in. plywood subfloor, and a 4-in.-thick reinforced concrete slab. The clearances were also quite tight when it came time to cut through the garage floor joists: the slot cut was roughly 3/16 in. wider than the width of the I-beam-allowing 1/16 in. on each side of the I-beam and 1/16 in. of “wiggle room.” The fit had to be that exacting so joist ends could be hung off the 2x12s bolted to the sides of the I-beam.

Thanks to Bob’s Iron of Oakland, California, for allowing me to photograph its crew at work.

Thousands of field-tested tips

This blog was adapted from Renovation 4th Edition, recently published by Taunton Press. Renovation 4‘s 614 pages include 250+ technical drawings, 1,000 photos from the 40,000 I have taken over the years, and thousands of field-tested tips and techniques that master builders have shared with me. I hope you find it useful. –Mike

© Michael Litchfield 2013