Build a Simple Shingle-Cutting Bench from Scrap Wood

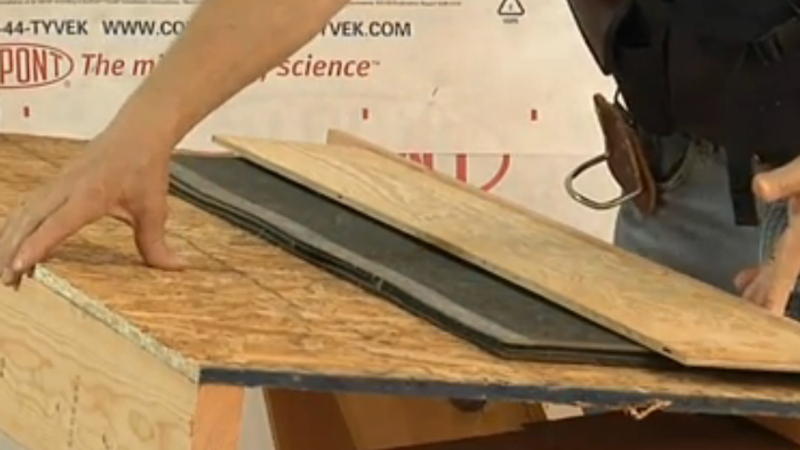

This angled bench is at a comfortable height for cutting identical-width starter strips for asphalt shingles.

If you need to cut some starter strips for asphalt shingles, you could drop to your knees and just cut them right there on the ground out of the bundle, but there’s a better way.

Bruce Guertin, from Coventry, Rhode Island, has made a nice, comfortable-height workstation for cutting these shingles that rests on top of his saw horses. The cut station is at least 3-ft. long (I’ve got about 3-1/2 ft. here) and a couple feet, maybe 26 in., deep. There’s a stop along the bottom edge that allows me to put a few shingles in so that I can load it up like a magazine. I’ve put a nailer down at the bottom so that I’ve got something to screw my stop into. (If the workstation was made of thicker plywood, I wouldn’t do this, probably.) And then I can leave enough room at the top of that so I can rest my straightedge, and I can run the utility knife along this and get exactly the same-width strip every time. I’ve got a 2×6 up under the top of the workstation that props it up, so I’ve got a nice work angle.

Once I get done cutting the shingle, I take the starter strip and stack it up here until I have a nice stack that I can hand off to whoever is doing the roof. It’s as simple as it could be, and probably it’s made of scrap stuff that’s just sitting in a pile. It’s a great tip, Bruce. Thanks for sending it to us.

_________________________________________________

Attention all tipsters!

We’re looking for any smart idea that would make a great There’s a Better Way Video or that could be featured in the Tips & Techniques department in Fine Homebuildingmagazine.

We pay for any tips that get published

You can post tips in our submit a tip blog, or just email them to Fine Homebuilding care of Chuck Miller. Thanks!

Plus, browse 30 years of great ideas in our Reader Tips department.

View Comments

I liked the article really easy tips for home building.

http://www.grannyflatfinder.com.au/builders-profile/

Or you could simply order the starter strips designed for this purpose. Just did my own roof using the pre cut starters for the rakes and eaves.

As they say, there's a better way.

Real roofers use starter strips, designed & manufactured for that purpose. some examples, among many possibilities, are http://www.owenscorning.com/NetworkShare/Roofing/10004070-Starter-Strip-Data-Sheet-Installation-Instruction.pdf AND http://www.tarcoroofing.com/products/roofapp/shingles/self-adhered/quick-roll-shingle-starter.

From a different angle: 'Real roofers' don't pay for their own materials; the home ower does... Who needs expensiv, excess single-purpose starter strip? The same shingle color run typicaly comes in a three-tab. Buy enough to cover your starter runs AND your caps. The lesson here is that know-it-alls may know it 'all' but not 'everything'.