Synopsis: Working with heavy timbers and no crane, the author moves material by hand. Implements like a peavey help, as does a raising device called a gin pole. These techniques are well suited to remote sites where mechanical help is not available.

When there were many gigantic redwood and fir trees in the Pacific Northwest, huge logs were milled into massive timbers to build saw-mills, bridges, wharves, warehouses and buildings for heavy industry. Lumber 12 in. square was common, though larger beams were also sawn. (The largest piece I’ve seen is 18 in. square and 42 ft. long, but the old-timers say they milled bigger ones than that.) The joinery of these structures was simple, relying on steel pins, bolts and plates for strength.

Today, many of the big-timber buildings are dilapidated beyond repair. Often the owner just wants to get rid of the old wreck, so salvage rights can be obtained before the wrecking crane is called. Salvaging any material is sound economy, and in recycled lumber there are some terrific finds like clear, tight-grained redwood, and well-seasoned fir that is suitable even for fine cabinetry. Used lumber, cleaned of paint and grime by rough-planing, sandblasting, and wire-brushing, reveals a new and rugged complexion that’s quite pleasing to the eye, with nail holes and blemishes adding character.

Today, many of the big-timber buildings are dilapidated beyond repair. Often the owner just wants to get rid of the old wreck, so salvage rights can be obtained before the wrecking crane is called. Salvaging any material is sound economy, and in recycled lumber there are some terrific finds like clear, tight-grained redwood, and well-seasoned fir that is suitable even for fine cabinetry. Used lumber, cleaned of paint and grime by rough-planing, sandblasting, and wire-brushing, reveals a new and rugged complexion that’s quite pleasing to the eye, with nail holes and blemishes adding character.

We recently built a house using timbers purchased before it was designed. The timber had framed a navy warehouse in Eugene, Ore.; we bought 2,400 linear feet of Douglas fir 12x12s in 10-ft., 20-ft. and 30-ft. lengths, and 9x18s 32 ft. long. Many pieces had several coats of paint, and others were covered with dirt, grime and grease. The lumber was roughsawn and box-cut; its width sometimes varied more than an inch from one end to the other, and many beams were twisted along their entire lengths. Wide checks had further distorted dimensions. Broken nails and the torched ends of pins protruded from the surface — nasty stuff to work with. We pulled most of them with a nail puller and a crowbar. After the house was framed, we cleaned the exposed surfaces with a portables and blaster, keeping the nozzle moving to avoid gouging grooves in the earlywood.

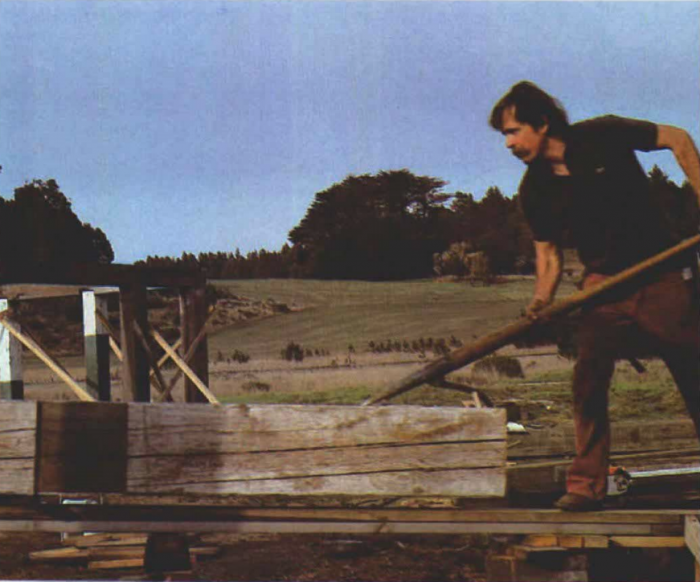

Moving and raising timber

Maneuvering heavy posts and beams is no great task if you’ve got a crane or boom truck. But the four of us on this job didn’t have access to any such large equipment. So we used a few old-fashioned but effective tools: a peavey, a sweet william, a pulley, a ramp (inclined plane) and a gin pole.

A peavey is a stout hardwood pole, usually of ash or maple, about 6 ft. long and hollowed at one end to receive a pointed steel pin. A tapered steel collar keeps the pin from splitting the end of the handle. The upper part of the collar is fitted with two eyes through which a bolt passes to secure a large steel hook, shaped like a fish hook, which swings parallel to the pole. If you want to move a beam laterally, swing the peavey so the hook digs into the side of the timber and place the pointed end on top. Lifting and pulling on the handle pivots the timber. It is easy to flop the timber over and over until you get it where you want it. If you hook the peavey into the end of a timber, you can make a dead lift…

To read the entire article and see more helpful illustrations, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

QuikDrive PRO300s

100-ft. Tape Measure

Anchor Bolt Marker