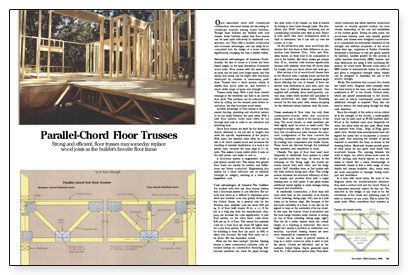

Parallel-Chord Floor Trusses

Strong and efficient, floor trusses may someday replace wood joists as the builder's favorite floor frame.

Synopsis: An engineer delves into the benefits of parallel-chord floor trusses, an engineered component consisting of two chords of dimensional lumber separated by an open wood or metal web. Other options, such as wood I-joists, are also available today, but this article offers a thorough discussion of a building component that still has some advantages.

Once associated more with commercial construction, structural trusses are becoming increasingly popular among home builders. Though most builders are familiar with roof trusses, fewer builders realize that floor trusses can be used quite effectively in residential construction, too. They offer a number of structural and economic advantages, and can easily be incorporated into the design of a home without significantly changing the way a builder builds.

Structural advantages of trusses

Traditionally, the size of rooms in a home has been based largely on the span limitations of standard wood joists. Floor trusses with the same depth as joists can be used over longer spans, and this means that rooms can be larger, with less space obstructed by columns or unnecessary partitions. Trusses have a much greater variety of depths than wood joists do, and therefore a much wider range of spans and strength.

Trusses rarely warp. With a joist floor, natural warpage in the members can lead to an uneven floor deck. This problem can be reduced somewhat by culling out the warped joists before installation, but that increases wood waste.

Another advantage of floor trusses is that they permit ducting, plumbing and electrical service to be run easily between the open webs. With a joist floor system, holes must often be cut through each joist in order to run electrical and plumbing lines.

Since floor trusses are sized by the fabricator, they’re delivered to the job site in lengths that meet the specific requirements of the project. With joists, the material must often be cut on site to fit, which wastes wood and increases the handling of material. Installation of a truss is relatively easy, because the truss edge is 3 1/2 in. wide. This makes it more stable while it rests on the wall plates, and easier to nail to.

A floor-truss system is engineered, while a joist system usually isn’t. This means that greater floor loads can usually be carried, and deflections are better controlled. Engineering also makes for a more efficient use of material (strength vs. weight), resulting in a lower per-square-foot cost.

Cost advantages of trusses

The builders I’ve worked with who use floor trusses believe that a floor-truss system is cost effective. But exactly how much so is difficult to determine since labor and material costs vary greatly throughout the United States. As a general rule for the Houston area, material costs are about $.90 per sq. ft. of floor (with trusses 24 in. o. c.). If the job is a long way from the manufacturer, shipping can increase the costs significantly. A joist floor system, on the other hand, costs about $.85 per sq. ft. of floor. This means that material costs for a truss floor are about 6% higher than for a joist floor system. But when the time saved for installing a truss floor (as much as 40%) is taken into account, the truss floor turns out to be about 10% less expensive overall.

For more photos, drawings, and details, click the View PDF button below: