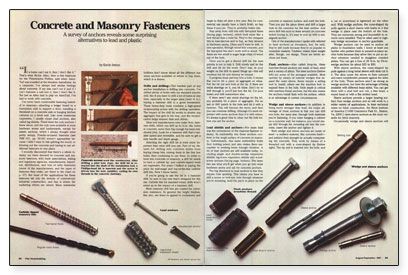

Concrete and Masonry Fasteners

A survey of anchors reveals some surprising alternatives to lead and plastic.

Synopsis: This is a survey of the various types of masonry anchors on the market, including a discussion of where each type is most useful and helpful pointers on how they are installed. It includes a list of manufacturers.

“If a horse can’t eat it, then I don’t like it.” That’s what Richie Allen, then a first baseman for the Philadelphia Phillies, said when AstroTurf was installed at the Houston Astrodome. As a carpenter, I’ve always had similar feelings about concrete. If my saw can’t cut it and if I can’t hammer a nail into it, then I don’t like it. But just as Allen had to play on AstroTurf, I’ve had to work with concrete.

I’ve never been comfortable fastening material to masonry—attaching a ledger board to a foundation wall to support a deck, installing a threshold on a concrete slab, or hanging kitchen cabinets on a brick wall. Like most residential carpenters, I usually chose lead anchors, also called lag shields. These were the only anchors I knew about, and the only ones available in most hardware stores and lumberyards, except for plastic anchors, which I always thought were pretty wimpy. Powder-actuated fasteners weren’t appropriate because I didn’t want to risk splitting the wood, or blowing out the concrete and having to use additional fasteners in one place.

I recently discovered that there’s a whole industry out there devoted to concrete and masonry fasteners, with trade associations, testing and regulatory agencies, manufacturers, importers, distributors, and lots of nifty fasteners. But most of the applications for these fasteners fall into the domain of commercial/ industrial construction, and that is where the marketing efforts are aimed. Many residential builders don’t know about all the different masonry anchors available or where to buy them, which is a shame.

Drills and drilling

The hardest part of any anchor installation is drilling into concrete. I’ve drilled plenty of holes with my standard electric drill. But if you have to drill a lot of holes at one time, especially in the larger sizes, buying a hammer drill is a good investment. These heavy-duty tools combine a high-speed reciprocating action with the drilling operation; The impact of the drill bit works to shatter any aggregate that gets in the way, and the reciprocation helps remove dust and debris. Look for a hammer drill that’s variable speed and reversible, and be sure to get a side handle and depth gauge.

Selecting the right drill bit is even more important than what drill you use. Part of my distaste for drilling into concrete stems from buying cheap bits, ruining them in the first few holes, then continuing to use them. In order to bore into concrete or masonry, a drill bit needs to have a carbide tip, and carbide-tipped tools are expensive. For years I balked at paying the price for mid-range and top-of-the-line carbide drill bits. Now I know better.

If you’re going to use the bit in a hammer drill, be sure to buy one that’s designed for this use. Carbide bits for standard rotary drills won’t stand up to the impact of a hammer drill.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Plate Level

100-ft. Tape Measure

Smart String Line