Metal Connectors for Wood Framing

There have been big advances over the years in some types of framing hardware, but many of these convenient brackets and hangers haven't changed since they were introduced.

Synopsis: In this timeless Fine Homebuilding article A California construction supervisor discusses the variety of metal connectors that are used in residential construction. This is a primer on how these connectors strengthen buildings and how they should be used.

A swallowtail scarf joint is an elegant way to make a tension tie between adjoining beams, and a housed dovetail will anchor a floor joist to a girder for the life of a structure. But not many construction budgets have an allowance for the extensive and meticulous cutting and fitting that it takes to achieve these time-honored joints. These days, most structural connections in wood-frame buildings are made with steel connectors because they are affordable and easy to install. Also, their structural values have been carefully tested and documented. Consequently, steel connectors are widely accepted by codes and building officials.

The companies that make metal connectors offer their products in a remarkable number of configurations. Their catalogs include not only illustrations of the connectors, but also tables that list specifications such as the dimensions of the lumber and the appropriate connectors, their design loads, and the number and size of nails it takes to achieve that rating.

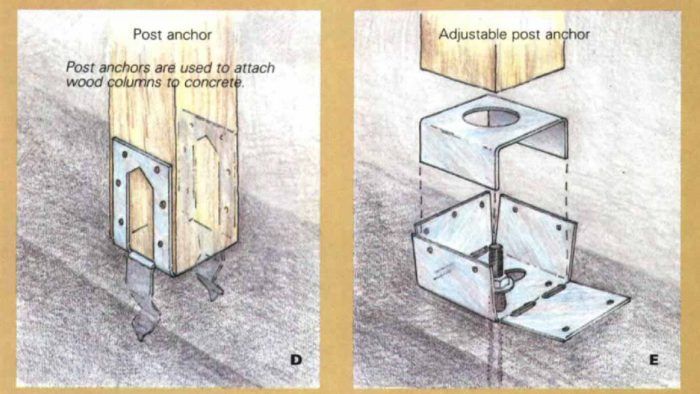

Joist hangers are probably the most common type of metal connector on a construction site, but if you need them you can get connectors to anchor a scissors truss to a bearing wall, adjustable post bases or metal clips that allow you to install outdoor decking without visible nails. This article takes a look at the principal types of steel connectors. Within these categories there are many variations that you can use to solve specific construction problems.

Concrete-to-wood connectors

If you have ever struggled to lift a framed wall onto a protruding row of anchor bolts, you are familiar with a potential source of frustration. Despite everyone’s best intentions, the holes in the sill plate sometimes don’t line up with the bolts, and the plate has to be redrilled. Or a stud lands on an anchor bolt, requiring a nasty-looking notch in the bottom of the stud.

One alternative to anchor bolts that circumvents these problems is the MAS galvanized steel anchor from Simpson. It resembles a Y with a ladle-like cup on the bottom leg that gets embedded in concrete. The branches of the Y are wrapped around the mudsill or up the side of a stud and secured with nails. Prior to the pour, these anchors can be positioned by tacking them to the formwork. And because they emerge from the concrete at the edge of the footing, you don’t have to hand trowel around a bunch of anchor bolts.

Another sheet-metal anchor from Simpson (called the MA) can be attached to the mudsill before you pour your foundations. The anchor’s pointy, arrowhead shape allows it to slip easily into the screeded wet concrete.

Seismic anchors (sometimes called hold downs or tie-downs) are frequently specified by architects and engineers when part of a structure needs lateral bracing and there is only a narrow wall section in which to provide it. The narrow wall is stiffened with plywood for shear strength, but when a horizontal load is applied to the top of a stiff panel, it wants to lift away from one of its corners. A hold-down provides resistance to this uplift…

For more photos, illustrations, and details, click the View PDF button below:

Plus, visit our comprehensive Framing Project Guide for more about constructing sturdy, high-quality homes.