Framing Headers and Corners

A summary of framing details for strength and energy efficiency.

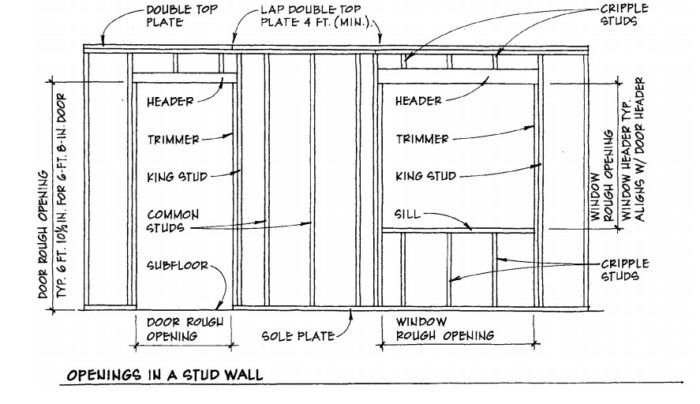

Synopsis: This is an illustrated guide to two framing details — corners and headers — that offers a number of options and materials for each. The author is Rob Thallon, who produced a similarly illustrated and authoritative guide to rough framing for The Taunton Press. This article consists almost completely of annotated drawings.

The walls of a building serve several important purposes: They define the spaces within a building to provide privacy and zoning, and they enclose the building itself, keeping the weather out and the heat or cold in. Walls provide the vertical structure that supports the upper floors and roof of the building, as well as the lateral structure that stiffens the building. Walls also enclose the mechanical systems (electrical wiring, plumbing and heating). To incorporate all of this within a 4-in. or 6-in. deep wood-framed panel is quite an achievement, and numerous decisions need to be made in the course of designing a wall system for a wood-frame building. There are two preliminary decisions to make that establish the framework for the remaining decisions. Once these are made, details such as headers and corner posts can be determined.

Wall thickness

Should the walls be framed with 2x4s or 2x6s? The 2×6 wall has become increasingly popular in recent years, primarily because it provides more space for insulation. This advantage comes at some cost, however. A 2×6 wall with studs spaced 24 in. o. c. (the maximum spacing allowed by codes) uses about 20% more material for studs and plates than a 2×4 wall with studs spaced 16 in. o. c. Ont he outside of the wall, the sheathing has to be 1/2 in. thick ( 1/8 in.thicker than sheathing on a standard 2×4 wall), and inside, the drywall also has to be 1/8 in. thicker to span the greater distance between 2×6 studs. Thicker insulation costs more, too. So, overall, 2×6 framing makes a superior wall but one that costs more. Framing the exterior walls with 2x6s and interior walls with 2x4s is a typical combination when the energy-efficient 2×6 wall is selected. Stud spacing of 2×4 and 2×6 walls may vary with loading, lumber grades and finish materials.

Framing style

Should the walls be built using platform framing or balloon framing? Balloon framing, with studs continuous from mudsill to top plate and continuous between floors, was developed in the 1840s and is the antecedent of the platform-framed wall. In recent years, balloon framing has been almost completely superseded by the more labor-efficient and fire-resistant platform-frame construction.

Headers and corners

Header size depends on wood species and grade, loading, header design and rough-opening span. Following is a rule of thumb for sizing a common header type, the 4x header:

For a single-story building with a 30-lb. live load on the roof and 2×4 bearing walls, the span in feet of the rough opening should equal the depth (nominal) in inches of a 4x header. For example, openings up to 4 ft. wide require a 4×4 header. The drawings in the PDF below show various commonly used solutions to the problems of tying adjacent walls together and providing weight transfer around openings.

For an illustrated guide to framing corners and headers, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

Short Blade Chisel

Protective Eyewear