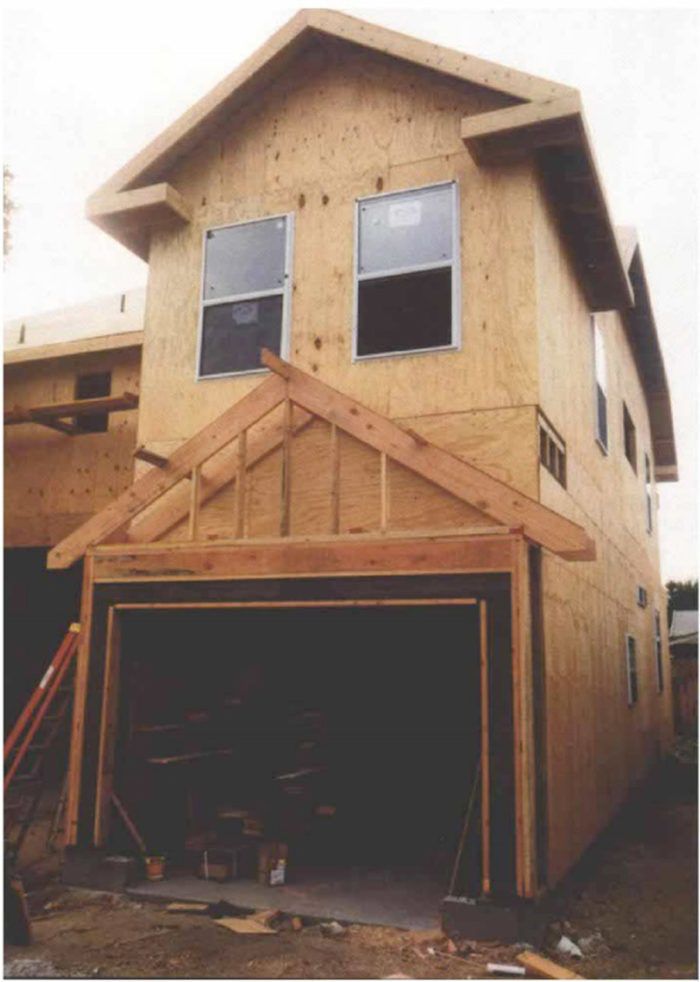

Synopsis: This article explains how to install rough framing at a garage door opening, with emphasis on the planning required for a smooth installation. A sidebar discusses the use of steel framing members.

The low hum and clickety-clack rhythm of an automatic garage-door opener is a sound of our times. And yet the ingenious hardware and signal receivers that operate the doors are affixed to the most basic form in building: a beam supported by posts or, as we call them today, a header on trimmers and king studs. Making sure the framing around the door is assembled accurately and with structural integrity is the topic of this article. Building a garage and getting it ready for a door typically involves several different trades, and it takes some planning to make sure the guy who finally installs the door can do a clean job with no complaints. After all, nobody likes to chip away concrete to make room for the door tracks, and nobody wants to pay for a custom garage door because the stock one didn’t quite fit in the opening.

Door types and sizes

Stock residential garage doors generally range in size from 8 ft. wide and 6 ft. 6 in. tall to 18 ft. by 8 ft. A good set of construction drawings will call out the garage-door details on the framing plans and on the elevation sheet. If the drawings lack this information, I check with the clients to find out what kind of vehicles they plan to park in their garage. For a mid-sized car, the typical door will have to be 8 ft. wide and 7 ft. tall. But most people want the flexibility of pulling a Suburban with a luggage rack into their garage, which requires a 9-ft. wide door that is 8 ft. tall. The extra width also reduces the chance of a driver ripping off the passenger-side mirror.

Here in the Wood River Valley in Idaho where I build houses, clients prefer sectional garage doors. They are made of four or more horizontal panels linked by hinges, with rollers that ride in tracks mounted to 2×6 side casings. The hardware that mounts over the door is attached to a 2×12 head casing.

Sectional doors don’t mount between the jambs. Instead, they mount just inside the garage and are sealed against the weather by stops nailed to the jambs. The weather seal is one reason why folks around here prefer sectional doors. For an even better seal, the stops can include weatherstripping.

In some parts of the country, people still use one-piece, or tilt-up, garage doors. These are less expensive than sectional doors and easier for builders, or homeowners, to install. One-piece doors fit between 2x side jambs that extend into the garage 2 in. beyond the plane of the header. The hardware is bolted to the edge of the jamb. Many builders make the mistake of using redwood jambs for this detail. Garage-door installers prefer Douglas-fir jambs because lag bolts hold better in them. Unlike sectional garage doors, one-piece doors require a 3/8-in. gap at each side to keep them from scraping the jambs during operation.

The type of door and the hardware it uses influence the ceiling height of the garage. The minimum overhead clearance for standard sectional-door hardware is 12 in. above the bottom of the head jamb, plus another 2 in. if the installation includes an automatic door opener. Reduced-clearance tracks that fit in a 6-in. deep space can be specially ordered from most manufacturers for low-headroom situations.

For more photos and information on framing for garage doors, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Short Blade Chisel

Plate Level

Smart String Line