Remodeling With Metal Studs

Skyrocketing lumber costs make steel studs an enticing, easily installed alternative to wood.

Synopsis: Light-gauge metal studs are lighter, cheaper and straighter than the dimensional lumber they replace. But using them means learning new techniques. This article shows how they can be used on a renovation project.

I recently went into a lumberyard to pick up a few 2x4s. The bill left me wondering if maybe I should have stopped off at the bank for a second mortgage. Sadly, anyone who has purchased lumber lately has probably had a similar experience. But what alternative is there to the high price and dubious quality of framing lumber? For more than ten years metal studs have been the answer for me. In Virginia, lightweight 25-ga. metal studs for remodelling are a little more than half the cost of good quality 2x4s.

I don’t suggest abandoning wood completely in favor of steel. Despite cost advantages, metal framing does have drawbacks that limit its effectiveness for total residential framing. Load-bearing partitions require a more costly, heavier gauge steel that has to be cut with special tools and must be welded or fastened with expensive drill-tipped screws. Also, the thermal conductivity of steel makes insulating a steel-studded wall more difficult. For these reasons I still choose wood for framing exterior and load-bearing walls. But for other framing applications, I find light-gauge metal faster, cheaper and easier to work with than wood.

Steel framing is stable and uniform

Until lumber prices went out of sight, material costs for wood and steel were roughly the same. I was using metal framing then because my labor costs were lower. The reasons are simple. Metal framing is a manufactured product, which means that it’s stable, straight and uniform. These qualities translate into time saved that would be wasted digging through piles of wood-framing stock, looking for acceptable material, and sorting and crowning at the job site. Product stability also eliminates the need to repair or replace metal framing members that warp or distort after they have been installed.

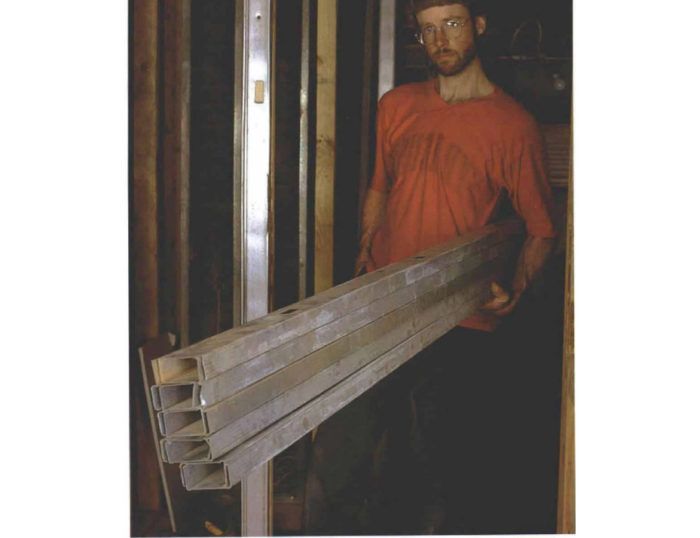

Metal framing is easier to handle than wood because it weighs significantly less. Studs, for instance, come in easy-to-carry, interlocking bundles of ten. Steel boasts other advantages over wood, including resistance to damage by fire, insects and weather. Steel framing is stocked in standard sizes from 1 5/8-in. to 6-in, widths up to 20-ft. lengths.

Lightweight steel framing requires no special tools

Chances are most of the tools needed for metal framing are already in your toolbox. These tools include a measuring tape, square, plumb bob, level (a magnetic level is handy but not necessary), chalkline and tin snips.

For most jobs, all that’s needed to cut metal studs is ordinary, straight-cutting tin snips. Metal cutting chopsaws that can slice through entire bundles of studs at one time are available for about $200. However, I’ve gotten along just fine all these years using tin snips to cut steel framing. Here’s how I do it.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Protective Eyewear

QuikDrive PRO300s

Bluetooth Earmuffs