Easy Boring in Concrete, Masonry and Stone

Choose the appropriate drill and bit for the job, then respect their limitations.

Synopsis: Concrete, masonry, and stone pose special problems when it comes to boring holes. This article is a detailed look at different types of equipment that can do the job, covering rotary hammers, hammer drills, and a range of specialty bits.

Builders once routinely used star drills to bore holes in concrete, masonry and stone. Star drills are straight, forged-iron shafts with star shaped chisels on one end. Operating a star drill is simple: The drill is beaten with a hammer while it is rotated by hand between blows.

Today’s run-of-the-mill masonry bits aren’t always better than star drills. Driven by standard electric drills, these two-dollar bits can bore at glacial speeds while their pretty zinc coats peel off like pencil shavings. Fortunately, if you bore more than the occasional hole in concrete, masonry and stone, there’s no need to suffer these indignities. The market is brimming with powerful, ergonomically correct impact drills and computer-designed masonry drill bits. Using the right equipment, you can easily bore the brawniest, grittiest and brittlest man-made and natural materials to accommodate everything from hardened screws to radon vents. This article describes the gear you need to bore holes in concrete, masonry and stone.

Standard drill, hammer drill or rotary hammer?

Who can resist picking up a tool called a Macho V or a Bulldog, pretending it’s a grenade launcher and knocking a hole through concrete with it? As their monikers imply, these tools and other rotary hammers bore big holes in concrete with minimal effort. But they’re overkill for boring lots of small holes, and their powerful blows can annihilate soft or brittle materials.

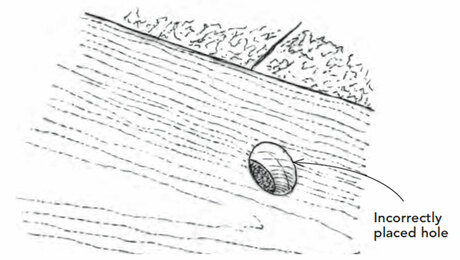

Standard drills are the best choice for boring brick, crumbly mortar, tile, old plaster, green concrete, soft limestone or other materials that might get damaged by percussion. In fact, standard drills and percussion drills that offer hammerless rotary action are the only choice for boring holes in old brick buildings to retrofit seismic anchors. High-quality carbide-tipped rotary bits are available for this purpose.

Hammer drills work best for installing small-diameter anchors

Hammer drills are a step up the evolutionary ladder from standard drills. Like standard drills, hammer drills have three-jaw chucks that drive round-shank or hex shank drill bits, and they perform basic rotary drilling in a variety of materials, including fragile masonry. But hammer drills can also add percussion to rotation. Pushing on a hammer drill that’s switched to rotary-percussion mode causes two percussion cams to ratchet against each other as the spindle turns. This step adds thousands of tiny hammer blows per minute to the drilling operation. Hitachi’s DV 20V2 hammer drill generates up to 41,600 blows per minute. This hammering action pulverizes materials to accelerate drilling, so caution is in order when hammer-drilling brittle materials. I’ve broken soft wall tiles with a hammer drill.

Within limits, the harder you push on a hammer drill in rotary-percussion mode, the faster it drills. Exceeding about 25 lb. to 40 lb. of pressure, however, can cause the motor to stall and overheat. Fortunately, it’s easy to develop a feel for top speed.

For photos and more on hammer-drill features that foster speed and accuracy, click the View PDF button below.