Q:

As a contractor, I’m often asked to build access panels in walls and ceilings for hidden plumbing or electrical systems such as shower mixing valves or spa motors. I’ve tried many different approaches, but I haven’t come up with anything that is easy to build, easily removable and attractive. Can you help?

Neal Rebholz, Babylon, NY

A:

Roe A. Osborn, a former associate editor of Fine Homebuilding, replies: The best access panel I’ve ever seen can be cut directly out of drywall or wood walls (tile takes a bit more work), it is trimmed in molding to match the rest of the house, and it doesn’t take too long to make. Here’s how it works.

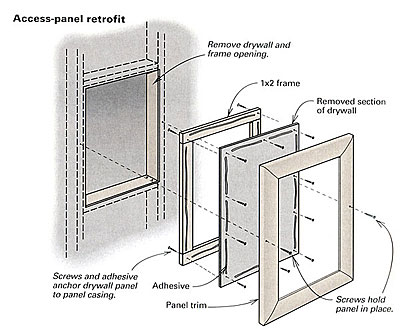

First, determine the size and location of the access panel, and lay out the top and bottom edges of the panel lightly on the drywall. Most panels don’t need to be more than the width of a typical framing bay (14-1/2 in.), and if you’re lucky enough to have the mixing valve fall conveniently between two studs, the inner edges of the stud bay will make the outside edges of your panel. If there is a stud in the middle of where you want your panel, go to the studs on both sides for the sides of the panel or keep the panel in the middle and plan on a little extra framing.

Once you’re satisfied with your layout, carefully cut out the drywall rectangle with a drywall saw or a utility knife. Be mindful of your saw depth as you cut to avoid pipes or wires behind the drywall. When you’ve finished cutting, remove the panel and set it aside. Now finish framing in the opening by inserting lengths of 2x along the top and bottom. I find that the easiest way to attach these framing pieces is by toe-screwing them into the studs and gluing them to the drywall with a little construction adhesive.

If the cutout has a stud in middle, I cautiously clip the stud with a reciprocating saw at the top and bottom of the panel. The drywall rectangle and the piece of stud should come out as one. Then I measure the thickness of my framing material (either 3/4 in. or 1-1/2 in.) and cut the stud back farther by carefully plunging the blade of my reciprocating saw through the drywall on the wall and holding the saw as level as I can. Now I have room to frame the opening, and the surgical slit from plunging the saw can be hidden by the trim.

I make a simple frame for the back of the panel out of 1×2. To reinforce the drywall and to provide a more solid place to attach the trim, I build the frame about 1/4 in. smaller in each direction so that it fits into the framed opening. I attach the 1×2 frame to the back of the drywall panel with construction adhesive and 1-in. drywall screws, and I drive the screws close to the outer edge of the drywall.

Next I round up some short lengths of trim left over from trimming the house. I make a rectangular frame for the panel 2 in. larger in each direction than the rectangular piece of drywall (3 in. if I need to hide the saw slits). I usually miter the corners and join them with glue and biscuits. When the glue has set, I mount the panel trim onto the drywall, again using construction adhesive and screwing from the back into the trim enough to hold it until the adhesive dries.

At this point the panel can be inserted into the framed opening. The trim hides the sawn edge between the wall and the panel. Because an access panel isn’t meant to be opened on a regular basis, I countersink screws on both sides of the panel trim that are long enough to screw through the drywall and into the studs. For ceiling panels I put screws on all four sides of the panel.

If looks aren’t a concern with your access panel or if you don’t care about the panel matching the existing wall, you can substitute plywood for the drywall and the 1×2 frame.

I’ve built at least a dozen access panels over the years, and these methods work best for me. There are no doubt many variations, refinements and different approaches to building access panels. So I’m asking readers to contact the staff with any ideas for the Q&A department.

View Comments

Great stuff! This would really work. I got my ceiling access panel here: https://www.bestaccessdoors.com/ceiling-attic-access-doors/

Very easy to use for my panel also.