The Lowdown on Levels

It may be the age of lasers and electronics, but a sturdy spirit level is still the job-site standard.

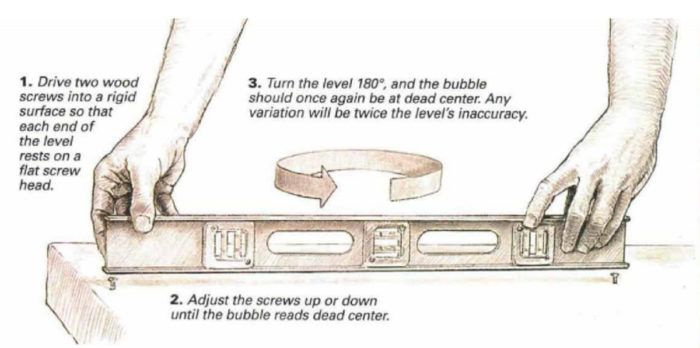

Synopsis: This is a survey of levels, a vital layout tool for many building trades. It lists pros and cons for the different kinds of levels on the market, including laser and electronic models, and offers a list of sources. A useful sidebar explains how to test a level for accuracy.

It has the last word on everything from framing walls to setting cabinets, but a carpenter’s level still leads a dog’s life. Knocked off staging, heaved in the back of pickups, dropped on concrete slabs, a level is expected to perform nothing short of a miracle: show even the slightest deviation from plumb or level. It’s little wonder that millions of them are replaced every year.

Even if you’re fussy about your tools, chances are good you’ll eventually loan your level to someone who isn’t. If it’s been a while since you bought a new one, you may be surprised that you have so many kinds to choose from. Outwardly, the spirit level is fundamentally the same tool it was when your great grandfather framed his cow barn. All you have to do is center a bubble between two lines to check a surface either for level or for plumb. But in reality, spirit levels are more sophisticated these days: They are made of new materials, have new kinds of vials and are more accurate than they used to be.

For a better idea of what the market has to offer, I toured factories where levels are made, talked to people who use them and sampled dozens of levels from different manufacturers. I wasn’t attempting a brand-by-brand comparison. Instead, I wanted to learn more about how levels are made and what features are important. Electronic and laser stick levels were especially interesting. But after using two makes of electronic levels, plus a handful of laser stick levels, I couldn’t help but think that they are special-occasion tools unlikely to dethrone the spirit level as the everyday king of the job site.

Whether you use a 2-ft. level to set cabinets or a 78-in. level for plumbing door jambs, the mechanics of how a level works are just about the same. The field is dominated by two basic types: solid wood, usually mahogany with brass edging, and aluminum extrusions. The differences between the dozens of brands and styles are in the details: the type of extrusion or wood frame and the type of vial the manufacturer uses. There also are a number of spirit levels specially suited for certain trades — telescoping levels for framers or magnetic levels that stick to steel framing or pipes.

Vials are the heart of a level, and many of them these days are made of plastic

A vial isn’t much more than a sealed container of liquid with a bubble trapped inside. Simple? It only looks that way. Manufacturers have spent a lot of time and money developing new vials and finding better ways of mounting them in their levels. Curved-glass vials, which once were your only choice, are still a traditional fixture on mahogany mason’s levels. But vials of acrylic plastic are a lot more common.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Code Check 10th Edition: An Illustrated Guide to Building a Safe House

A Field Guide to American Houses

DEWALT Impact Driver (DCF885)