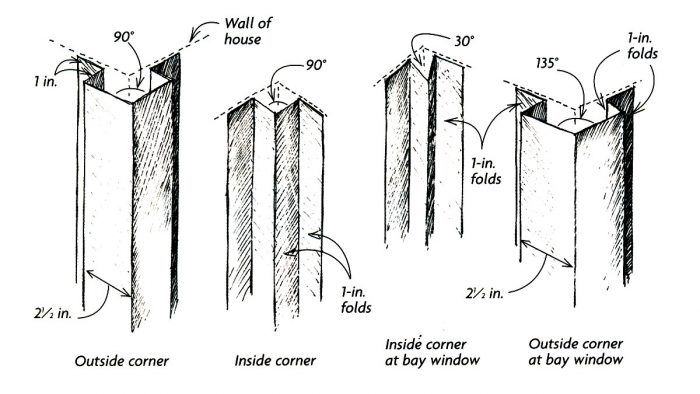

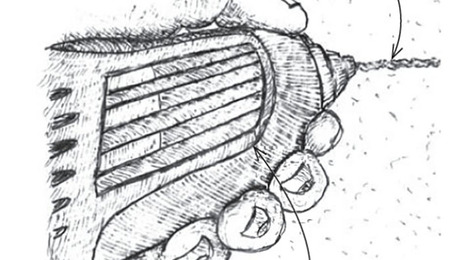

I’ve been installing a lot of nonwood sidings over the past few years, such as cement-based and hardboard lap sidings. To complement the clean look of these sidings, I’ve taken to installing custom-made steel corners. As shown in the drawing, the corners have flanges that are nailed to the wall and act as integral flashings in case any moisture gets behind the siding. The siding abuts the projecting corner of the metal trim details.

I have a local metal shop make the corners from steel gutter stock. This material is inexpensive and comes in brown, white or primer. The steel corners hold paint beautifully.

Before I started using these corners, I used cedar corner boards. They would eventually shrink, leaving a cracked caulk joint. That problem is a thing of the past with the steel corners.

—Richard Darby, Merlin, OR

Edited and illustrated by Charles Miller

From Fine Homebuilding #120

View Comments

If you are installing Hardiboard clapboards why wouldn't you use Hardiboard stock for the corner boards? Like materials with proper caulking would hold up longer than mixing metal with cement boards.

I think it is a good idea given caulk joints do eventually fail . In this case the flashing remains intact and the siding can expand and contract over it. I wonder why not use aluminum ?

I also wondered why not aluminum? Not rigid enough? You could rip 1" rigid foam board into 1" X 1" strips to fill the hollow space, giving the aluminum flashing some body and add a bit of insulation at a critical point.

From my (one-time) experience of having a garage built by a crew that didn't have any history with Hardieboard I found it frustrating convincing them to follow the instillation specs. This article makes me wonder how the Hardiebord company feels about their product being butted up against steel or aluminum. Warranty?