Reinforcing Cabinets for Concrete Countertops

Learn how to beef up a cabinet to hold the weight of a concrete countertop.

Q:

After reading Building Concrete Countertops, I’m interested in trying the process. How can I make my cabinets strong enough to hold the weight of the concrete?

Brenda Melchior, Salt Lake City, UT

A:

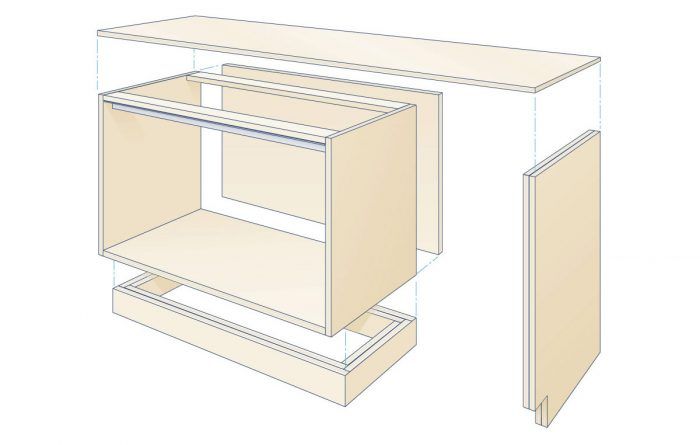

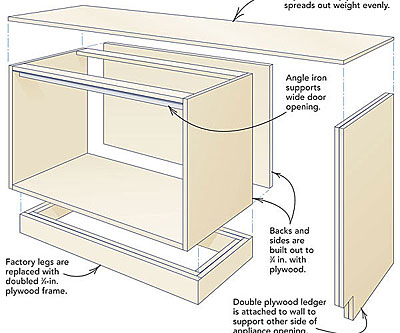

Fu-Tung Cheng, co-author of Concrete Countertops: Design, Forms and Finishes for the New Kitchen and Bath, replies: We generally install our countertops on custom cabinets made of 3/4-in. plywood on the back, sides, and top. These cabinets easily can handle the weight of the countertop without being reinforced.

When we’re asked to install one of our countertops on standard factory cabinets, those cabinets usually have to be reinforced. Reinforcement should start with the bases. If adjustable plastic legs support the cabinets, we remove the legs and replace them with frames made of a double thickness of 3/4-in. plywood. If the cabinets have integral kick frames, we reinforce those frames with 3/4-in. plywood.

Next, the cabinet backs should be reinforced. Factory cabinets that we see typically come with 1/4-in. thick fiberboard back panels set into a rabbet in the bottom and sides, and in the stretcher along the top. We remove the back panels and glue them to 1/2-in. plywood panels, bringing the total thickness to 3/4 in. After widening the rabbets to accommodate the extra thickness, we reinstall the back panels.

If the sides are less than 3/4 in., we build them up to a 3/4-in. thickness as well. For a wide span such as a sink base, we often reinforce the door opening with a length of 2-in. by 1-1/2 in. angle iron. If the countertop spans an opening—as for a dishwasher where there’s no supporting cabinet on one side—we make a ledger out of two layers of 3/4-in. plywood glued and screwed together to support the countertop.

With all the carcases reinforced and installed, the final step is gluing and screwing on a single layer of 3/4-in. plywood to reinforce the top. This plywood layer helps to distribute the weight of the countertop evenly over the cabinets, and it provides a flat, level substrate for the countertops.

View Comments

Excellent suggestions, but in a kitchen remodel don’t forget also to check the floor for its ability to hold the weight of the new cabinets and concrete or stone countertops and reinforce it as necessary too.