Beautiful Trim from Plywood

It's a stable and less expensive alternative to solid wood.

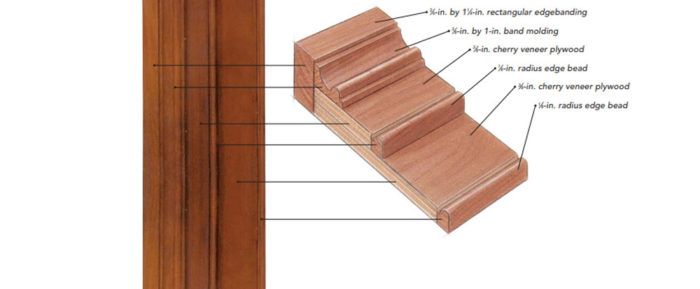

Synopsis: Given the declining quality and rising cost of hardwood, plywood has become an appealing choice for interior trim. Here you’ll learn three different techniques for hiding the raw plywood edges, and you’ll also get some alternative trim designs.

Prices are up, but hardwood-lumber quality is down. If you’re disappointed with this state of affairs but still want good-looking trim in your house, you might want to investigate engineered products, such as veneer plywood.

Because of its balanced, cross-ply construction (that is, thin layers of wood with lots of glue to restrain them), veneer plywood is not susceptible to the mutating forces that bedevil ordinary lumber.

Genuinely warped or twisted plywood is difficult to produce unless you leave a sheet of it out in the rain. Swaybacked plywood, resulting from careless storage practices such as deep stacks or inadequate support, is corrected easily by slight hand pressure during assembly. If need be, any unwanted set can be reversed with the process of strategic clamping, or “training” it back to flat.

Finally, veneer-core plywood is stable in another important way. It is far less sensitive than solid wood to fluctuations in humidity, and it expands or contracts only a third as much as Honduras mahogany, a species notorious for staying put.

Plywood also is significantly less expensive. At current local prices, using solid material instead of paint-grade birch or maple plywood means tripling my materials costs, including veneer edging. Hardwood lumber costs me at least twice as much as an equivalent amount of same-species plywood.

But using plywood is not all roses

To be fair, however, at about 75 lb., a 3 ⁄4-in. thick, 4×8 plywood sheet is bulky and heavy. Breaking down a full panel with a circular saw or a tablesaw without side and outfeed support can be awkward and slow.

There also are indirect costs. You may have to purchase full sheets, forcing you to store more material than you want. Some suppliers sell partial sheets, but this seeming benefit usually comes with a surcharge, which can be hefty. Also, lengths beyond 8 ft. typically are a special-order item, and any savings gained in materials tends to evaporate.

Another downside is that face veneers are normally no thicker than 1 ⁄32 in., making veneer-plywood trim too delicate for use in barrooms or fraternity houses. Where trim work will receive merely normal levels of abuse (e.g., outside baseboard corners), veneered material is still not the best choice. For other trim applications such as window and door trim or moldings that are located off the floor, however, this fragility doesn’t come into play.

Finally, unless striped edges are a design element, they must be concealed. It takes time to apply even the simplest banding, such as iron-on or pressure-sensitive veneer tape, but not much more than removing saw marks from lumber.

Wood moldings such as back banding, either plain or with a profile, are applied to the edges of plywood in much the same manner as solid wood. These moldings, either store bought or made with routers and tablesaws, are nailed and sometimes glued to stable plywood edges.

For more photos and techniques on using plywood for trim, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

The New Carbon Architecture: Building to Cool the Climate

Code Check 10th Edition: An Illustrated Guide to Building a Safe House

A House Needs to Breathe...Or Does It?: An Introduction to Building Science