6 Ways to Stiffen a Bouncy Floor

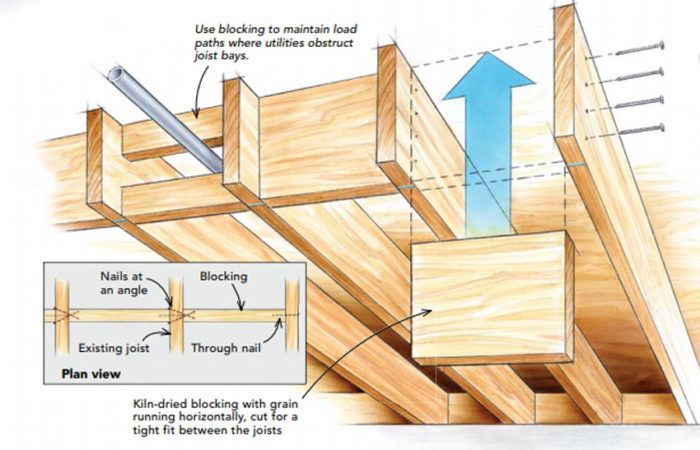

Solid options for reducing joist deflection include added blocking, sistered joists, built-up beams, and more.

Synopsis: Bouncy floors are one of the most vexing problems faced in houses, both new and old. Contributing editor Mike Guertin teams up with structural engineer David Grandpré to detail six common, and not-so-common, ways to stiffen up the floor joists to reduce deflection and keep the china cabinet from wobbling.

If you haven’t fallen into the basement of your house already, don’t worry; your bouncy floor is probably not an indication of a disaster waiting to happen. Floor deflection is common in older homes because the floor joists often are smaller or are spaced farther apart than the joists in modern homes.

Of course, new homes also can have bouncy floors if the joists are approaching the maximum spanning distance for the building loads they are supporting. Long-span joists may meet framing design criteria and the building code, yet still feel uncomfortable.

Some bounce in floors is good

A well-designed wood floor feels stiff as you walk on it but still gives slightly under foot, absorbing some of the impact of your steps. Too much bounce, though, can make the china cabinet wobble. You can shore up floor joists and reduce the bounce in a number of ways, but the six methods outlined here represent a mix of common and not-so-common solutions. The best choice depends on access to the joists, obstructions in the floor system, or current remodeling plans; one technique or a combination may be your most practical solution.

It’s important to make these improvements carefully. If existing joists have been weakened due to rot or insect damage, glue and fasteners won’t hold well, and your work may be ineffective. Loose blocking or an underfastened subfloor won’t bring any benefit, so take extra time and care during installation. Also, you can use jacks to relieve the load on joists while the work is being done. Jacks improve the effectiveness of your floor-stiffening work.

1. Built-up beams are rock solid but reduce headroom

This solution works best in crawlspaces where you aren’t too concerned about limiting headroom or cluttering the space with columns. If you don’t mind the obstructions or loss of headroom, though, beams and columns certainly can be added in basements, too.

Details

The important thing to remember when adding a support beam is also to add proper footings to support each column. In most instances, a 2-ft.-square, 1-ft.-deep footing provides adequate support. However, when you’re installing LVL or steel beams with wider column spacing, larger footings may be necessary to support the load.

The beam size depends on the load and span of the beam between columns. Also, keep in mind that the closer you space the footings and columns, the more rigid the new beam will be and the stiffer the floor will feel.

To make a new footing, cut the slab, dig out the earth beneath, and pour concrete flush with the top of the slab. Next, snap a chalkline across the underside of the joists in the middle of the span to help align the new beam. Use post shore jacks, screw jacks, or hydraulic jacks to lift the new beam into position beneath the joists. Finally, cut and install new columns to fit between the beam and the new footing.

For more photos and information on fixing your bouncy floor, click the View PDF button below.

View Comments

If I may interject here to add a bit of insight to the blocking comment. There is a considerable difference between standard blocking and the installation of an IBS2000 Load Share Connector System. (as shown in the thumbnail pic) . Engineered technical differences in deflection and vibration are documented and substantial when IBS2000 connectors are used along with adequate strapping below and glued and screwed sheathing above. Kenkeknem Smart Build can provide these numbers for comparison with any floor you may have in place.

Thank you gentlemen.

http://www.ibs2000.com

1-778-754-7522

The IBS2000 load system allows joist spans in excess of the usual code spans. The system allows an architect to specify the same joists as used on the rest of the floor and avoids a raised floor on part of the floor plan. The problem however, is that carpenters and other tradesmen don't understand the system. They were installed in my house, but not to specification, and the subsequent HVAC contractors just knocked them out of the way as they would with usual diagonal bracing. I had researched the system and during my inspection I brought it to the attention of the builder who's response was "what's wrong with that". ...and thus began the process of me educating one more individual.

These type of problems are not isolated to the IBS2000 system but occur when any new and unusual building technique is introduced. There are no certifications required except for plumbers and electricians and no on-going educational requirements within the building trades. (I won't go into what I've seen in the field with the Zip system.)

Burb guy (and others),

"Prints? Prints! We don't read no stinkin' prints!"

My experience was along the lines of "Simpson? Who needs them when we have a bunch of 16d nails?" I found my experience reading FH & JLC had deluded me into thinking everyone had the same standards & knowledge I see in the magazines.

There have been several articles lately (https://www.jlconline.com/training-the-trades/how-will-construction-solve-its-skilled-labor-crisis_o?utm_source=newsletter&utm_content=Article&utm_medium=email&utm_campaign=JLC_091519,)

It's clear there's a real lack of respect for the trades in America (less so in Europe) and that we need to correct that. John Gardner said, "A society that respects its plumbers less than its philosophers will soon find that neither its pipes nor its ideas hold water."

BUT, the flip side is that to earn that respect, we have to insist on good workmanship and as you note, tradespeople who view education as a lifelong process. "We've always done it that way." just doesn't make the grade any more.

FWIW, when I clicked on the IBS URL above, it was all in Korean, which I can't read. Try https://ibs2000.business.site/

If you are starting with fairly moist joists (eg a new build), diagonal bracing is actually better than solid blocking, because as the joists shrink, the braces tighten in place (wood has very little shrinkage in the lengthwise direction).

Good, informative comments. Thank you.