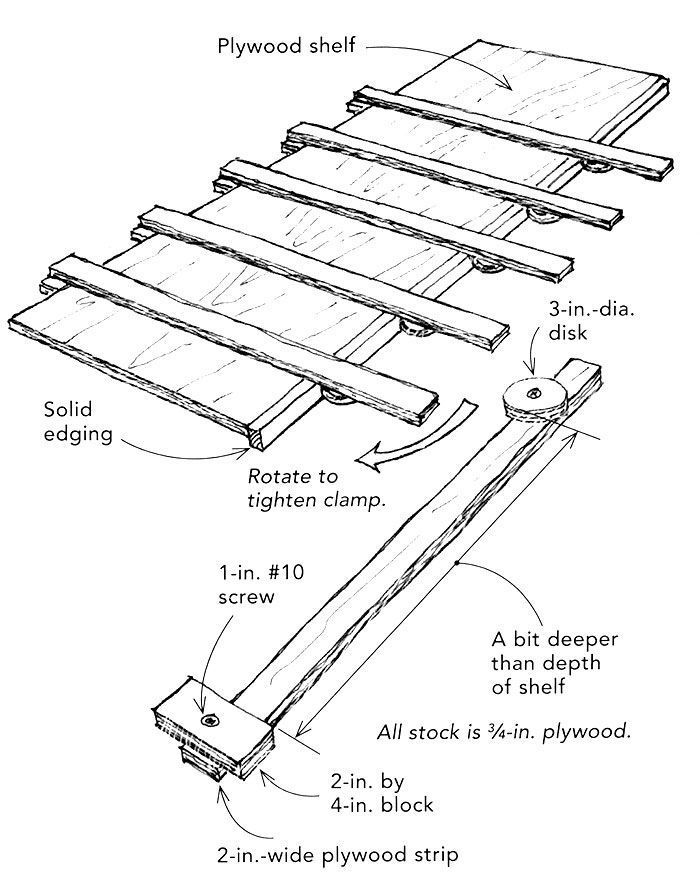

I make a lot of built-in desks and shelves. I use hardwood-veneer plywood for the top surface, and I attach hardwood nosing to the front edge with biscuits. This method requires that I clamp the edge to the plywood wherever there is a biscuit. On a recent project, I needed more pipe clamps than I have in my collection, so I came up with the economical but effective set of clamps shown in the drawing at right using ordinary material from around the shop.

Each clamp consists of a 2-in.-wide strip of plywood at least a foot longer than the depth of the workpiece. I mounted a 2-in. by 4-in. block of the same material to one end of the strip with a #10 wood screw. I then cut a circular piece using a 3-in.-dia. hole saw. I mounted this to the plywood strip so that the distance between the circle and the block was a smidge deeper than the shelf to be clamped. Again, a single #10 wood screw was the fastener. I drilled pilot holes for the screws to make sure the blocks sat flush against the plywood strip.

To use the clamp, hang the blocks over the back of the shelf and the edging, and rotate the strip sideways. The clamp squeezes the edge and the shelf between the circular and square blocks. The circular block rotates slightly, but the friction between all the moving surfaces holds the clamp tight.

Michael Hoff, Boxborough, MA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #209

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

Reliable Crimp Connectors

Handy Heat Gun

View Comments

Clever.

Couldn't one use rectangular blocks on both ends of the long strip? (easier to cut) Since they are both fastened with one screw, they would both rotate when the squeeze is applied. This approach would also allow control over how wide the applied force of each block is.

A different approach using circle blocks would be to drill the hole off center and use the block as a cam to squeeze.

The idea of the single screw on the disc is so it would roll as a wheel. It doesn't drag the edging. If you use a moving block on the botton, the friction against the edging would drag it when you tighten the clamp.

Great tip ! And one of the best I've seen on edge clamping. Thanks for sharing !