Remember the opening to The Six Million Dollar Man? “Gentleman, we can rebuild him. We have the technology … Better than before. Better. Stronger. Faster.” That’s what I thought of when I learned how Tech-Wood’s engineers created a high-grade wood-composite siding from a material they call Wood 2.0.

Basically, they break down a tree and rebuild it so that it’s impervious to water and insects. They start by slicing pine along the grain into mini-toothpicks about 8 mm to 10 mm long. The strands are then cooked, oriented in the same direction, injected with liquefied polypropylene, and extruded into 12-ft. and 16-ft. lengths of siding.

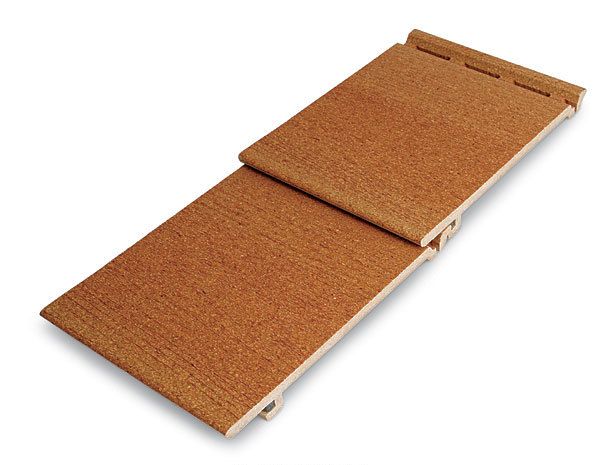

Similar to vinyl siding, the extrusions have a fastener channel along the top edge that is covered by the board above, and its back is vented with a 1/2-in. airspace. The siding can be screwed or nailed to the sheathing, and Tech-Wood claims that even 16-ft. lengths can be installed by one person because the product is lightweight, rigid, and self-leveling. Plus, unlike fiber cement, it can be worked with standard tools without creating a plume of silica. Unfinished siding weathers to a gray similar to western red cedar, but it can be painted, stained, or purchased prefinished (shown here) in eight solid colors or four semitransparent stains. Tech-Plank is available in four profiles and comes with a 50-year guarantee.

Comments are closed.