I have a construction topper on my truck, and I wanted to add an inexpensive sliding platform to the bed for easy access to assorted tools and materials. I looked into commercial slide-extension units and liked everything about them except the price, so I built my own.

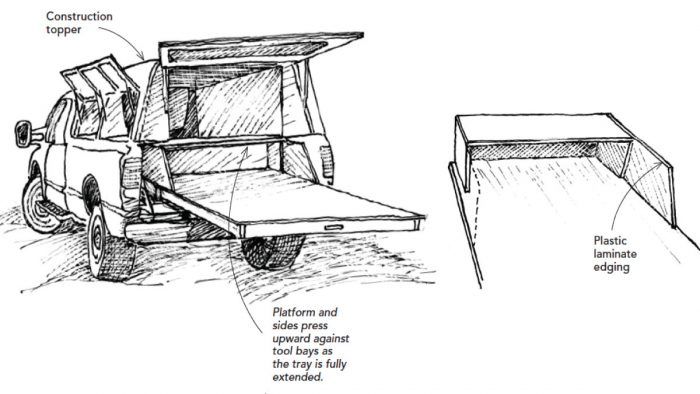

As shown in the drawings, I made a 4-ft. by 8-ft. tray out of 2×4 stringers and a 3/4-in. MDF top. It’s constrained by an MDF bottom with 2×4 sides. Both tray and bottom are screwed and glued for a sturdy build.

A 1/2-in. gap on each side between the tray and the 2×4 sides limits binding. The tray rolls on 20 heavy-duty 4-in. casters spaced evenly next to each stringer and affixed with screws and construction adhesive.

I screwed a piece of 3/4-in. plywood to the top of the open tailgate to bring it into plane with the tray bottom. As the tray is extended, its upward travel is constrained by a raised platform and partial sides at the back as they bear against the underside of the topper’s tool bays. I can extend the tray a bit over 5 ft. beyond the tailgate.

I added a barrel-bolt latch to keep the tray from sliding open on an incline, but friction alone is a mighty strong force to keep the tray where I put it. In fact, the biggest drawback is that it can be tough to open or close the tray when the truck isn’t parked level.

Because the tray takes up so much room, I was not sure if I had made a mistake at first. But after several months I came up with an efficient packing system, and now I would not be without it.

—Gregory Bowden, Cincinnati, OH

Edited and Illustrated by Charles Miller

From Fine Homebuilding #212

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

8067 All-Weather Flashing Tape

Reliable Crimp Connectors

View Comments

I have seem a similar design at http://4wheelonline.com blog, but pretty complex this is way easier to follow and understand.

mine is far easier & cheaper i think & sometimes i have to empty the bed of the truck to get more material in the truck. i cut 8 pieces of 3/4" PVC 2" short of tailgate. i cut 2 pieces of 1/2" MDO 2" short of tailgate by 2' wide. i screwed 4 pieces of 2x 20" long on the MDO.. i then screwed 1 piece of 2x to each end of the MDO & screwed a heavy duty handles in the top center of each piece of 2x (so it 2 makes tool trays 2' wide with the length just short of the truck bed). i set the 8 pieces of PVC spaced evenly apart on the truck bed. the 2 sleds of MDO slide easily in & out on the PVC for access to tools in the back. if i need to empty the truck, i place 2 sawhorses (4' wide) as high as the tailgate short of the length of the sleds apart with 1 sawhorse at the edge of the lowered tailgate. grabbing a handle i can slide 1 tray at a time all the way out of the bed on to the 2 sawhorses. depending on the material i am getting, i can either remove the PVC & put back in after unloading material or leave the PVC in. i unload & slide the 2 MDO sleds back on top of the PVC. however, i am going to put a taller MDO piece on the sides & each of the backs of the MDO sleds to prevent sideways tool movement on the trays.