Builders once routinely stapled up sheets of polyethylene plastic on interior walls before the drywall went up to stop the flow of moisture-laden air into exterior walls. With moisture stopped in its tracks, condensation and resulting water damage could be prevented.

Or so the theory went.

More recently, building scientists have questioned this once common practice. Water intrusion from both the inside and outside is more or less guaranteed over the life of a building, and the question becomes whether a layer of poly traps moisture inside walls where it can lead to mold and rot or helps to keep it out in the first place.

That’s the subject of this week’s Q&A Spotlight. With a house in upstate New York, the writer describes a wall assembly that includes both a layer of rigid foam insulation on the outside, and a layer of poly on the inside. Is this wise?

Find out what the crowd (and building science expert Peter Yost) have to say about it at Green Building Advisor

Further Resources:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Pretty Good House

Code Check 10th Edition: An Illustrated Guide to Building a Safe House

Get Your House Right: Architectural Elements to Use & Avoid

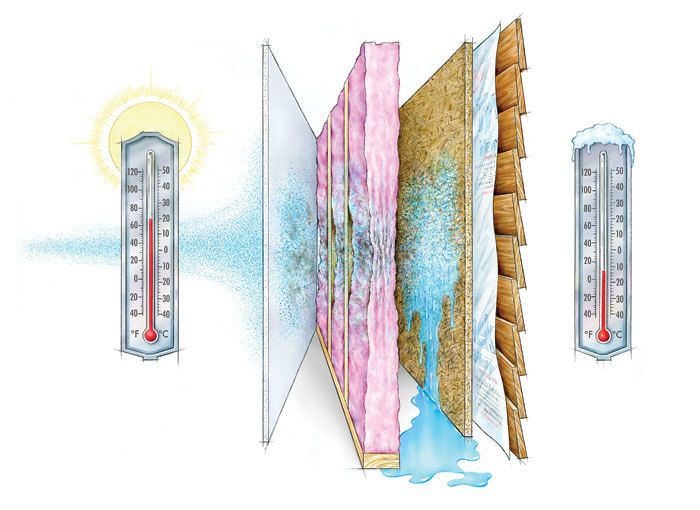

Where moisture comes from: Water vapor can be forced into wall assemblies from the warm side of the house. When it reaches a surface whose temperature is below the dew point, condensation occurs.

View Comments

Yes Vapor barriers are a good idea,depending on what part of the country your located in ,moisture can create many problems ,no matter what the season or location. It is what type of moisyure barrier you use and where that makes up the great differents in cooling and heating cost.

Yes Vapor barriers are a good idea,depending on what part of the country your located in ,moisture can create many problems ,no matter what the season or location. It is what type of moisyure barrier you use and where that makes up the great differents in cooling and heating cost.

The title of this article should have been "Too Many Vapor Barriers Are a Bad Thing". The wall assembly on which the GBA article is based contains two - the poly, and the rigid foam insulation. The advice is to get rid of one of them. This is sound advice but in my opinion their recommendation gets rid of the wrong one.

The illustration within this article is only half the story as we go from a winter to summer situation. This process of causing condensation by hitting the dew point can occur in either direction so the idea of creating a vapor barrier out of a single layer of poly sheeting should be actually on BOTH sides of the insulation layer. This is why using spray polyurethane foam is so much better. It creates a vapor barrier on both sides of the insulation material naturally so it will prevent condensation forming in either direction. Yet another reason why foam insulation is worth the extra expense.

Re: Housewraps: are there special fasteners and/or other considerations for installing housewraps on a steel framed structure?

bvlbrx

8/23/10

I would have to disgree with the concept of providing a vapor retarder on BOTH sides of a wall sytem. Yes vapor drive happens in both direction depending on the time of year and climate. Yes spray polyurethane foam is an effective vapor retarder by itself. But that is the point - as long as the spay poly is the sole insulating material, it is very effective.

The problem with the subject wall system in the GBA article is that it used both rigid foam and batt insulation and threw in an additional vapor retarder to boot.

A better solution would have been to increase the amount of rigid insulation and eliminate the batt entirely. Then place the vapor retarder on the exterior side of the sheathing and not inside behind the gypsum board.

Up here in Canada we get rather extreme weather. We had a problem years ago called the Leaky Condo. Tens of thousands of these existed after a number of years despite being built to the national building codes (very similar to yours). I worked with a gentleman who built condos for four years when he was younger. He told us that his boss instructed the drywallers to slice the vapour barrier prior to boarding as his thougths were that the moisture would get in and you had to let it out. When I heard this back in '99 I told him that that was exactly out theory in boatbuilding and ship repair. You can't keep it out! But if you leave it in you will have problems.

Sorry, I neglected to mention that as of 2007 none of the units he worked on ever needed their respective envelopes replaced.

HOUSES/BUILDING SHOULD BREATHE JUST LIKE THE REST OF THE PLANET!

I would empirically and experentialy be driven to the fact that all living things breathe, not by artificial means but by the simple act of transpiration. Why it it so difficult for most designers, builders and code writers to wrap their heads around this simple concept? Heat sinks or mass energy retention with real transpiration dynamics are an obvious 'research' area to go into and explore. And with that thought why do the building industries; be it residential, commercial, or industrial continue to deny the reality of the specific climatic criteria of a given "zone" and pretend that 'ONE' size fits all?

There are a multitudes of zones and each with their particular/individual criteria and demands. I for one would suggest that the search be for natural system(s) that are flexible enough in terms of adjustments to fulfill both heating and cooling requirements - cognizant of the unique and individual climatic zones. It is sad that in our modern quest/denial we have overlooked that they figured 'IT' out, many centuries if not millennium ago for a great many of the various and unique climatic regions across and around this planet. Why do the ''ADVISORS'' continue to refuse the wisdom of design and the building materials of the many builders that proved their abilities, knowledge and efficiencies long before we arrived within our so-called scientific analysis era. An extremely inconclusive and exclusive 'HUMAN ANALYSIS' that has yet to be proven in 'any' human field of endeavor as a successful or sustainable mode of interaction between our own human-driven life-style/energy demands and our one and only planets' (EARTH) ecosystem.

I am deeply concerned that your advocacy of high tech solutions that advocate very high-energy embodiment/footprints in terms of production,promotion, transportation, maintenance, with very short electronic lives (before replacement) will only serve to disconnect we very frail humans from the reality of the climates and the very ecosphere we are so fortunate to inhabit. The introduction of systems that remove us by means of automated/and environmentally demanding 'techno-illogical' products and controls only further serve to disconnect us from the real local environments we live in. And I am convinced through my years of study,research,and teaching that these artificial circuit breakers will only jeopardize our survival as a species. It is my opinion that the more we isolate by technological means, avoid direct interaction/control within our homes and workplaces we will continue to deny the the lessons learned long ago, our energy demands will continue to grow and as a result our lives, our environment and one the ONLY spaceship we have will suffer to the point of having to remove our kind from its list of passengers! Sailing on without us.

Regards, smalld

If you didn't see it - maybe you weren't paying attention!

So what all at means is we should "shiver in the dark"?

One of the components that compounds the problem here is the OSB sheathing [AKA - mold candy]. As noted above, too many vapor barriers adds considerably to the issue, but the more I use OSB, the less I like it. Consider a practical example: I used to lean sheets of 1/2 CDX fir against the side of my shed and leave it there for 10 months - exposed to the weather. When I needed it, I threw it on the truck and used it. When I did the same with OSB, it fell apart in my hands when I handled it - now 7/8 of an inch thick.

Here's another issue I've seen: House gets framed, dryed in, and hardwood floor installed over 15lb felt [asphalt permeated]. Then the house sits for 3 years in foreclosure - still dryed in but not conditioned [heat/cool]. When we started work on it, patching the floor in some spots, the OSB subfloor was saturated. There was a vapor barrier on the crawlspace floor below but I could smell the mold in the OSB. Chemicals, heaters, dehumifiers, etc and we dyed it out but I never smelled mold on CDX fir on the hundreds of renovations I've done over the past 25 years

If plywood manufacturers could put a mold inhibitor in the OSB [and strengthen the glue], that would help when vapor barriers are misapplied

Sometimes I think we have made things way way to complicated. For some this is job security, afterall if we did not changes things daily what would these writters write about and how would they make a living. Say what you will, but many houses built with an interior poly, unfaced FG batts, and insulation boards/corner bracing, work very very well. Just a fact, even with 2x4 framing. Make a few more changes, like 2x6 on 24 oc, window and door headers built into the rim joist above .....

All this furring, rain screen, exterior interior foam ....... adds head aches, labor cost and yes rot in some cases. A little air exchange saves alot of time, money, and head aches.

I had an issue with tyvek trapping moisture in the winter.As the vapor tried to leave the interior it hit the tyvek which was below freezing turning the vapor to ice. When it warmed up during the day enough to melt but the tyvek would not let it pass through in water form and it never got warm enough to form vapor so it soaked the osb. I noticed this first on the north walls.The homes had vinyl siding so I could unzip the panels. There was an inch of ice between the tyvek and osb which was black and swelled to 1 inch.Has anyone had similar problems?

That was not my surprise by looking the illustration and by perceiving me that the vapor barriers situation is bad?: he should always be on the hot side of the insulation.

two solutions to vapor seem possible, enclose the rot senesitive materials in impereable bariiers, i.e., poly to th einterior and exterior, or use breathable housewrap to the interior and still draft-stop every place possible.

As any wood worker knows OSB is ALL end grain. This means it is a giant moisture sponge( aka mold candy). OSB was never a structural material and was never meant to have any permanent place in any building. It was meant to be a cheap temporary sheet material.

The problem arises when we have engineers and architects guiding an industry that they have no practical experience in. They may draw pretty pictures...BUT you cannot live in a piece of paper.

The next problem is the use of pink and other fiberglass batt insulation. These batts actually allow air ,wind and moisture to pass through and thereby absorb and hold moisture promoting moulds. "Roxul" batt insulation is near solid stone fibre and does not allow wind or moisture to pass as well as repelling water and moisture

Green and blue drywall is"supposedly" moisture resistant and yet it absorbs moisture and promotes mould on both side of it.

Many builders install windows with tiny little opening at the bottom of the window. Remember HOT AIR RISES!!! Smoke from your burning toast also rises. Did you forget your basic grade school science class?

ALL of these problems are as a result of builders NOT doing their own homework themselves and letting supposed qualified individuals ie. Engineers and architects guide an industry in which the majority of them have absolutely no practical experience whatsoever.

My profession is restoring century homes. I have learned from the past 100 plus years the success and failure of many products and building systems. I also work on many brand new buildings which often show the results of failed systems within months of completion.

Many building codes are so completely wrong and yet builders blindly follow them. We need to change this system.

Lose the Tyvek. Lose the fiberglass insulation. Lose the tiny cheap windows. Lose the OSB and those silly OSB "I" beams.

We need to think about building things to last for 100 years and not waste precious resources building temporary buildings that barely last 10 years before they have to be renovated.

Our building ancestors would laugh in our faces if they were to see the crap we build today.

I'm a big believer in closed cell spray foam, But what do you do when the customer doesn't get it and cheapens out for the batt. I make them sign off on the declining of recommendations on the contract and can't be held responsible for moister, mold issues later. As far OSB vs CDX the test reflect the both have the same negative effects with moisture, but at least CDX doesn’t crumble like OSB. We don’t do a lot of new construction so we don’t use a lot of exterior sheathing, but when do I Tyvak and Roof Paper with Stinger Cap Staple Gun. I we did more new construction I would only use Zipsystem. The only reason I don’t use it for all my exterior sheathing projects is because because most our additions are less then 25sheets and my local suppliers only sell it by the bundle which I think is about 50sheets.

The product is brilliant and cost the is about the same as 1/2” CDX. We’re getting ready to start a ground up project and ran it by the architect to include. He loved and changed his specs so update you all later.

Think about it? it cost about $10-11bucks a sheet and no rapping, no tears, no staples. Just nail and tape all seems. No hassles No nonsense!

Hi.. Nice article and very informational. Nice overall blog site really loved it..

We are a new start up company in the domain of green designs we cover everything from green office design to rain water harvesting to waste management..

DO visit our site and let use know what you think..

http://www.greendesignexpert.com

If you look at this logically, the problem is, wood is hygroscopic, it absorbs water vapor when it is cold, below dew point! But wood that is warm, that is to say above “dew point” does not absorb water vapor. Therefore the trick is to ensure that the wood frame keeps warm by having enough external insulation or by raising the indoor temperature.

So you have several approaches, one add lots of heat to the home to keep the frame warm. Add external insulation that is thick enough to keep the wood above dew point, when you are trying to save money by using very little heat. Use a dehumidifier to keep the humidity below dew point. Stop breathing, sweating, cooking and washing to keep water vapor out of your home. Leave your home empty during cold weather.

If you keep your indoor temperature at 70°f and your relative humidity 65% then dew point is 57°f.

If you change your relative humidity to 45% then dew point is 47°f.

Obviously from a long term cost point of view, installing enough insulation, works out cheapest, it does away with some long term substantial costs. But then if you move every seven years?