Moving construction material on the job site and working with the Laborer’s Union.

“The captain said to John Henry, I’m gonna bring that steel drill round. I’m gonna bring that steel drill out on the job, I’m gonna whup that steel on down.”

–from “John Henry,” a traditional American folk song, as taugyht to me byAfrican American carpenters on job sites in Los Angeles, Calif.

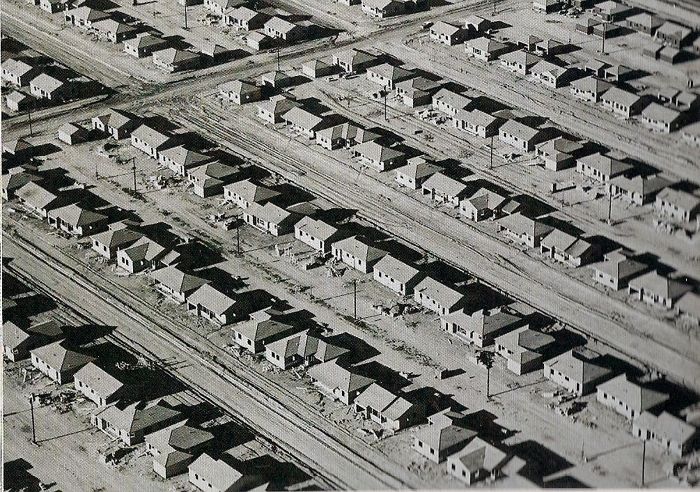

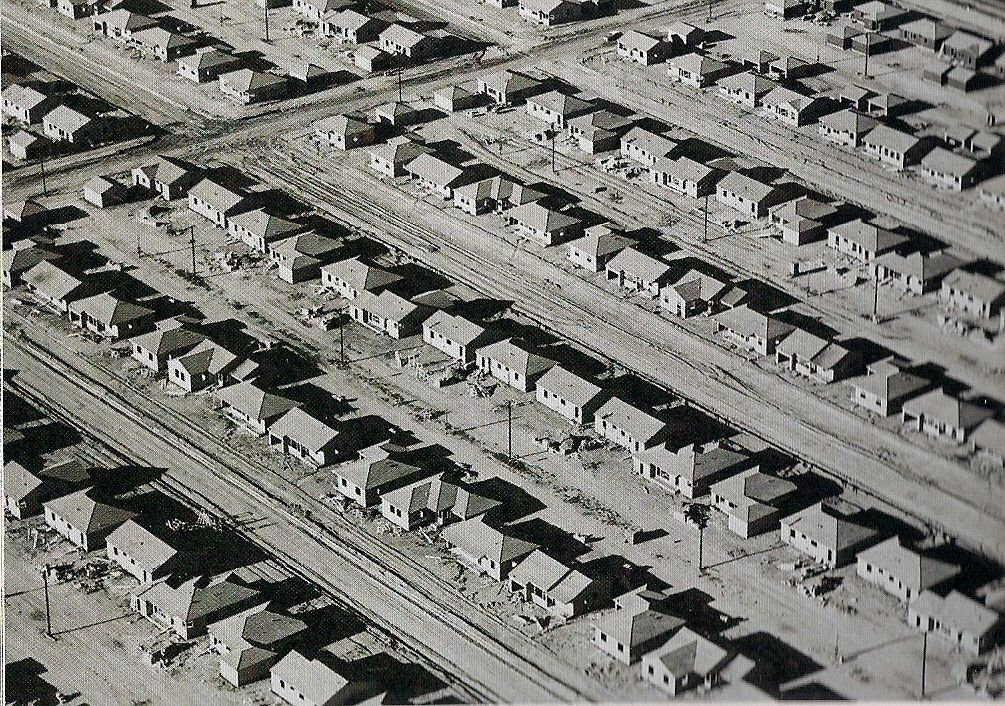

We didn’t have forklifts and small tower cranes on our building sites in the 1950s, but we moved tons and tons of joists, plates, studs, and sheathing material without them. The amount of building material being shipped into Los Angeles from old growth, straight grain, Douglas Fir forests in the Pacific NW was huge. This blog is part of the story of moving these materials as we went about our jobs of building an endless number of homes mainly for returning vets.

When I arrived in LA in 1950, the house building industry was still controlled by the old-time unions. I say old-time not to put them down, but these folks had lots of rules that didn’t fit into production framing. And, like most of us, they were hesitant to change and go with the times. I joined the carpenter’s union in the fall of 1950 in Beverly Hills—Local 1492—and was sent out to help frame a house.

The controlling factor in material movement was the Laborer’s Union. Not much moved on any job site unless their members did the moving. As a beginning carpenter, I would sometimes spend all day cutting a lift of rough 2x4s to stud length with a hand saw. These studs, along with other materials, were carried by union laborers to union carpenters nailing it all together. I got laid off that job (fired), because I already knew the basics of production framing and didn’t fit in with how they built a house.

The laborers I knew were a hard working class. Not only did they move heavy materials, often up 2 or 3 floors, but they dug the ditches, moved 500 pound bathtubs, and all the rest of the “dirty work.” To my knowledge, they were not allowed to use any carpentry tool except a hammer to pull nails. This was one union rule that was rapidly coming to an end.

We started contracting in the early 1950s building tract houses and apartment buildings. The first union laborer we hired was Martin Garcia standing around 5 ft. in height. Martin had “waded the river” as a young man looking for work. For years as a migrant worker, he picked grapes under the vines in N. California. This “on the move” work was tough once he started a family and besides he got “tired of dealing with snakes, spiders, and tarantulas under the vines.” He finally settled in LA and found work as a laborer.

We had learned early on to have lumber trucks dump our material where we wanted; mainly as close as possible to where we were working. From these piles of materials, Martin spent his entire workday moving joists, plates, sheathing, studs, and joists for carpenters. Let me say that Martin was one of the best laborers I have ever known.

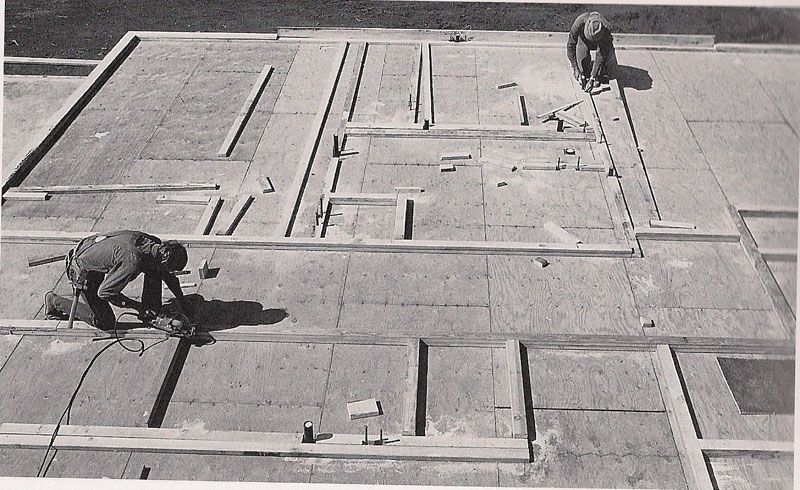

As the company grew a bit, we hired another laborer, Martin’s son, Johnny. It wasn’t long before we had him nailing sheathing to floor joists, building walls, and doing other “carpenter” work. Johnny too was short. His 18” framing hammer handle almost hit the ground when stuck in a loop in his nail apron. With smart workers around like Johnny, the shift from laborer to carpenter was on.

In the early 1960s as we moved into larger projects, two and three story apartments, lumber movement became more difficult. Laborers would stand by a pile of studs and throw them, one by one, up to the 2nd deck. On a three story structure materials had to be carried up the stairs or passed, like long 1×6 deck sheathing, hand over hand up the side the building. Something had to give.

Our solution at that time was to invent a “lumber loader” that would move studs, joists, and even heavy beams up as far as the roof of a three story building. It was a simple device welded together from tube steel in ten foot sections based on some farm machinery we had used back home in W. Nebr. Two metal booms were attached to a 4 ft. x 6 ft. frame that sat on the ground. A link belt chain ran around the booms with a hook attached about every six feet. This was powered by a 220 volt motor. As the chains moved, laborers would set a load of materials on each hook and remove them when they reached the floor where we were working. It was a huge time saver and, once in place, worked quite well.

And then one day brother Joe rented a fork lift to move some materials around a new job site. That pretty much signaled the end of our lumber loaders and also of the Laborer’s Union working with carpenters.

By the early 1970s, we owned four large Champ forklifts with telescoping masts that could lift several thousand pounds up to near thirty feet, if I recall correctly. An entire lift of studs, for example, could be set on a deck near to where we were building walls. We kept Martin on the job sites, but most of the labor work was now done by a carpenter grabbing a bunch of studs and nailing them in a wall. We built a number of structures over subterranean garages. On these buildings, we rented smaller, propane driven forklifts to carry all our materials to the back of the building. We set these smaller lifts on the concrete deck with a Champ forklift.

The best forklift operator I knew that worked with us was Francis Hui from Hawaii. Everyone on every job site had a nickname. Francis, of course, was called Pineapple—-what else? We all steered clear of him when he was on the forklift. He was a bit reckless, but he could put materials wherever you wanted. He was just a little crazier than most of us. Then one day he didn’t show for work. We inquired and found out that he was in the LA General Hospital with self-inflicted bullet wounds in his abdomen. We visited him one evening. I recall being thrown out of the hospital because a friend and I were racing each other in wheelchairs up and down the hall. Rules again! I lost track of Pineapple after that.

The overall history of the labor union’s struggle against mechanization is a long one that needs to be treated elsewhere. Let me just say that the union lost in the building industry. The rules of the game had changed. Like the carpenter’s union, most everyone had to abandon old rules or die. Carpenters were not going to work with short-handled, curved claw, 16 oz. hammer no matter what the rules said. Mechanization changed the rules of the construction industry. Backhoes dug ditches, cranes lifted all kinds of materials, and air guns drove the nails. You either changed or became irrelevant. Laborers became carpenters or retired. That’s the hard truth in our world, no?

The biggest change, of course, in how we frame houses came when the Skil 77 circular saw came into our hands. With this saw we were in carpenter’s heaven. It, like the forklift and other mechanical tools, radically changed how we worked and how many people it took to build a house. The first house framing job I worked on in 1950 was built using 10 carpenters and 4 laborers. Not many years later, I was framing tract homes with just a partner.

And then the stationary tower crane arrived on the scene. These cranes are fed material by a forklift. The material is then spotted wherever you wish on multi-storied buildings. It is especially useful when you don’t have access between buildings or to the back side.

So change goes on often displacing trained workers. Technology is everywhere on a job site these days. For better or worse we workers often get overrun by it all. We either change or become irrelevant.

Maybe you have comments on how all this has made you or your parents change. Thanks.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

Affordable IR Camera

Handy Heat Gun

View Comments

I got into framing in the early 70's and it was my job to hump rafters and studs, after all the teco nailer had to have something to do in between his teco tasks..........

Thanks for sharing a part of our home builders history and heritage Larry.

I use to build bunk orders for Wickes lumber also, and I was considered the fastest and most dangerous lift operator like pineapple.But I got more lumber out of that yard than any other operators combined.If I remeber right....12 homes in 1 day......studs,rafters and plywood. Of course back then everything got framed in 2-3 days and your cuts would fill a five gallon bucket. Todays tracks take 2-3 weeks and their cuts almost fill a damn dumpster.What a shame.

Anyway,I appreciate your writings Larry.Thanks

Larry I have really been learning alot from your blog .And you describe the transitions through the ages perfectly. Unfortunately I feel like as we technologically advance we lose something in our craftsmanship. We lose something in the speed of production as we bypass all the detail that was once so meticulous. Don't get me wrong I use the technology to get my job done as fast as I can but I as a carpenter have been finding myself seeking inspiration in older and older carpentry. Something triggered in me when I realized that the carpenter that was my foreman couldn't drive 12 d nails without his Paslode. And when I mention meticulous detail my thoughts go back to last summer when I while at the seashore wandered on to an 1874 lighthouse called " Hereford Inlet Lighthouse " a carpenter gothic style structure . I walked around and enjoyed all the detail . But what caught my eye and dawned on me that it wasnt the specific style but the "mind-set of the craftman of the era " was that each and every piece of lumber exposed to the eye had a chamfer on it. I had noticed this at other Victorian era homes as well as my own. And as I walked around the back and looked at the covered porch I realized even though we build it the same , these craftman took an extra step to make the edges softer to the eye. And basically just put more "art" into it . I have yet to see a new deck with any kind of chamfer. It just looked so kool.

They even had a "scarf joint " clearly visible on the front rim joist of the the porch.Was it original ? Was it a repair ? Asilent mystery . It was a moment when i felt like i didn't really know any carpenters who could or would do these things. Even though the style obviously has changed are we becoming worse carpenters just going through the motions?

When i returned to the city we replaced a door on an old Victorian brownstone . When it came time to duplicate the meticulous woodwork detail around the inside and outside of the entrance I kept requesting we put a chamfer to imitate what was once there and what was also on the other doorways on the street. My foreman replied, after shooting the idea down repeatedly and then with a less than inspiring order of how the trim work wood go he said, " I don't even know what the hell a chamfer is? "

You guys might enjoy a book I recently read - Tales From the Trades by Frank Freeley

Such an interesting and educational read. I have to agree fully that today we are all so very pampered with the existence of a generous amount of technology that assist us in our daily operations. This fact is especially beneficial when we need to perform some moving of items which are humanly impossible to accomplish. However, I guess people in the past were not so fortunate as us today. Everything involved great physical manual labour that required days or even months to fulfill. That is why I am so grateful towards our forefathers who have greatly contributed towards building of our nation without the aide of machineries.

Things have truly changed so much over time hasn't it. So many people overlook the fact that we used to be able to get by with our own two hands and the sweat on our brow to pull us through the things we need to do. Even with machines and equipment that help us with moving and other chores, we should never forget that we could still achieve the same if we put our backs into it.

Reading that first line immediately brought to mind how the Egyptians probably will feel when they compare who we carry out construction and storage now in comparison to how they came up with construction and storage solutions in the past with the great pyramids! Haha!