When Did I Become a Locksmith?

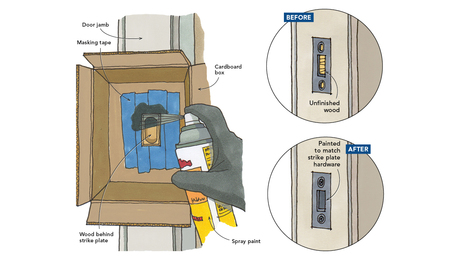

This is what a carpenter resorts to when the job is supposed to be done in a week but the faulty custom door lock would take weeks to replace.

We were finishing a job last week, the two young lads and I. I set them up to install the luxury vinyl plank floor in the basement, and after watching them for a time to be sure they understood the task, I headed upstairs. There, the marine varnish had finally dried on the mahogany front door and I could set the fancy entry lock.

The lock was a D-handled Emtek, the kind with a thumb latch on the outside and a $400 price tag. These aren’t particularly complicated to install, and the door was pre-bored for the lock. I only needed to drill one additional hole for a screw to secure the bottom of the D-handle. Half an hour, I figured.

Two hours later I finished.

The first hint of trouble was when the square spindle from the thumb latch wouldn’t align with the square hole in the latch itself.

“Huh,” I thought. “That’s weird.”

My immediate thought was that I had done something wrong, so I went looking for the instructions. There weren’t any to be found other than the template for boring the door.

So I tried fiddling with the assembly again, partly depressing the thumb latch to turn its spindle to get it to align. By doing this, I could get the lock assembled on the door, but it turned out there wasn’t enough throw left on the thumb latch to fully open the main latch.

Clearly there was something wrong with the lock.

“Call the manufacturer,” I thought. Then, “But they’ll probably just tell you to return the lock for replacement.” This being a special-order lock, I figured that would take a couple of weeks and we were scheduled to finish this job this week.

“Well, let’s see. How hard can it be to figure out how the lock works?”

Not that hard to figure out, as it happened. Two screws held an assembly in place from which the misaligned spindle jutted. Removing the screws freed the assembly so I could look at its guts. They consisted of a rack and pinion setup where the thumb latch moved the rack upward, and its teeth engaged the pinion gear on the mis-aligned spindle, thereby turning the spindle and moving the main latch. An eensy-tiny spring pulled the thumb latch back into position when released.

After fiddling around with this for a few minutes, I realized that when the thumb latch was assembled to the rack and pinion, the spindle pinion had to start out in the right place on the rack. One tooth too far in either direction and the spindle wouldn’t align correctly.

And now began the game. I had to guess at the right alignment, assemble the rack and pinion, preload the spring, put the assembly back in place with one hand while holding the D-handle with my other hand, and then install the screws using my tail. Then, I had to install that assembly on the door to see if I got it right.

All without losing the eensy-tiny spring.

This went as well as you might think.

Eventually I got it, but not before my back kinked up from hunching over in a chair for two hours like a Harry-Potter goblin working on some clever safe mechanism at Gringots.

The good news was that the two lads did a bang-up job on the flooring. The words I’d spoken to them about layout hadn’t been in vain, and on top of that they’d figured out the gyrations required to snap together the vinyl planks. Pretty good for a couple of young men from the much-maligned millennial generation.

Andy Engel is a lead carpenter for Hudson Valley Preservation in Kent, Conn.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

Reliable Crimp Connectors

8067 All-Weather Flashing Tape