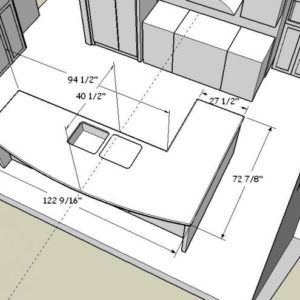

Where would your granite countertop contractor place the seam or seams for this one?

If the seam were to parallel the short leg and break the curved cantilever into two, would your guy reinforce the joint with doweling, or an epoxied-in bar on the underside?

Replies

How much is the overhang?

I'd really like to see the seam on the red line as I believe it will give you least noticeable appearance but that will be dependant on how large of a slab of granite you can get?

Locally I can get up to about 120", don't suppose you could shrink that a few inches hunh?

Depending on how much the overhang was I might not worry about it too much, I would at least run a bead of silicone or epoxy (which ever you are using for seam fill) along the edges before pushing them together.

If you are worried about it you can have your fabricator trough out a few 1/2" x 1/2" areas that match each other on either side of the seam and install metal rod in the field set in epoxy. I've only had to do that once and it was a PITA

Edit: I just looked at the drawing again, are you using standard depth 24" cabinets for front of the island?

If so you're going to have about a 15" overhang on the back edge and need some sort of corbel support anyway, can you plan them for one to fall on the seam and space them in pleasing manner from there?

Edited 10/9/2006 11:00 am ET by CAGIV

The overhang begins at 7 inches at the ends, and "bows" out to 13 inches maximum at the center.

I myself wouldn't worry to much about re-inforcing the seam, you'll be at about 10"? and should be fine.

I would check with your supplier as to what they suggest the max un-supported overhang is. I'm not very familiar with Granite we do mostly Quartz tops and the max overhang they suggest is 12".

From what I've been told and read, granite needs more support then Quartz because of it is not as consistant of a material and the veining in a wrong place can be a deal breaker.

Are you planning any sort of support to help hold up the middle where it gets out to 13"

I don't know about where you live but I wold try to keep the bar top full length and seem it on the return

I've worked on jobs where they have had 11' and 12" material supplied. This is Calif and there is alot of importers here and alot of comercial work going on. I would suggest you try to find a supplier that has longer material and try making your material choices from that. It also depends on the size equiptment that your fabricator has. This might be a reason why "he can't get longer material".

Also, it depends on the size of truck the shop has, too. Where I live now, most shops pick up and install their materail in full size one ton pickups. So this limits their lengths to 8-10'. They tend to be smaller shops where I am now.

Another problem that you might encounter is that the larger slabs might cost you more money in the end if you yield doesn't work out either. But he shouldn't be charging extra fabrication costs for waste material, even though some places try. It all depends on how the proposal is written. One of the shops I have dealt with in the past charges me for the material and then for the fabrication costs. This works well for both of us because I tend to pay less in the long run because He isn't trying to add for extra material if he can't find the perfect yield slabs.

If you do buy an extra sheet, use it in full back splashes or make sure you keep the waste, if you want it. If not, it gets put in the bone yard and they will sell it to someone else, again.

No matter what you do, get the homeowner to approve the slabs and where the seam placements will be before you cut or sign the contract, if you can(most shops can have slab yards put the slabs on hold for a week or more, depending on the fabricator reputation. I have heard horror stories and been apart of one when a unknown fabricator(yes, lowest bidder) put in too many seams on a job just to save on material. Fortunetly, I wasn't part of that contract, he just screwed the cabinets removing the tops.

Edited 10/9/2006 12:02 pm by migraine

my granite guy ALWAYS places the seams between two pieces.

the only way to do it...

Namaste

"The truth, when told does nothing but bolster a mans character." -Big Cal Stew 2006

"There are 2 kinds of people in the world, those who divide the world into 2 kinds of people and everyone else" -Gloria Steinham

"The shrub administration is a bunch of Focking CrIminals" -Me

Well lemme tell ya li'l cowpoke...

when a snake falls in love with the spaghetti, it's time to buy a new hat... - Scott Adams

I may not want to admit it but I'm a fool for your stockings I believe... ZZ-Top