I’m not a framer. How should I do this?

I’m framing some shear walls in my parents’ old barn, which has been converted into a wine press house. With most of the second floor removed, there’s not a whole lot to keep it from toppling over.

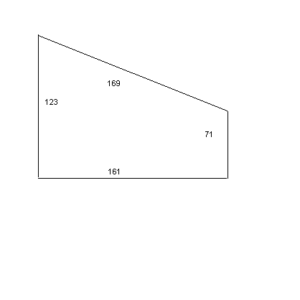

I’ve attached the dimensions of the wall I was working on today, in inches.

I’m no framer. Geometry is not my strong suit. I spent most of this afternoon scratching my head and trying to figure out what I’m doing. There’s no room to frame these walls on the floor and lift them into place, so I’m stuck stick-framing them.

Figuring out my varying stud heights is killing me. I eventually made some progress by chalking the entire wall out on the floor (in another location). I just pretended that the floor is level, which it isn’t, and that the adjacent wall (71″ high) is plumb, which it isn’t. The post on the left isn’t quite plumb, either.

Would you do this all this with just the Pythagorean theorem? Or is there some dumbass way of doing this efficiently? I’ll add that mocking it up on the floor was painfully slow.

Edited 11/5/2007 6:04 pm ET by Biff_Loman

Replies

Mad props to you framers, btw. I was using an air nailer, and it is deceptively heavy. And heights make me nervous. You manly men, you.

Plumb and nail the first two and measure the difference and add or subtract that # for the next ones..but if the floor is way out, I'd shim the bottom plate level.

Spheramid Enterprises Architectural Woodworks

"If you want something you've never had, do something you've never done"

Good lord, that sounds like the ticket. I'm also framing a door in these walls, so I'll place it such that one of the king studs falls on the stud lay-out. So I'll only have to measure for three studs in the wall. Also, using that method, I can start from the *short* side and work over to the side that's 10' tall. Trying to drop my tape measure that far was a b1tch.Right on.Edited 11/5/2007 6:24 pm ET by Biff_Loman

Edited 11/5/2007 6:24 pm ET by Biff_Loman

Depending on your sheathing / sheetrock choices, the 16 or 24 layout doesn't have to be exact. I'd cut em long, plumb em up and nail away, just be certain to have a 4' and 8' and 12' or what ever the break will be, be on target.Spheramid Enterprises Architectural Woodworks

"If you want something you've never had, do something you've never done"

Even if they end up being a tad off to not work with layout the cost of an extra 2x for a scab isn't horrible.

I think I'd have shimmed the plate level like you suggested so you could just take the common difference and be done.

Edited 11/5/2007 6:28 pm ET by CAGIV

That and I am beginning to be a convert to floating butt joints on sheetrock. A spline of osb behind the butt seems so much easier.Spheramid Enterprises Architectural Woodworks

"If you want something you've never had, do something you've never done"

This is great. Thanks guys.All in all, it was a pretty humbling day. Before I could even start, I had to move quite a number of grape bins out of the way using a forklift. I operated a forklift, once, a year ago, for maybe an hour. It took me a looooong time to haphazardly scatter the bins, which had been stacked together very neatly.

Biff,

Build it as two walls.

Build the red wall first.

Then build the blue wall, and use that forklift of yours to lift it up onto the first wall.

Build it so that when yo lift the top wall all the way up against the ceiling, there is exactly the space of a 2x, between that wall, and the wall below it. (The yellow in the picture.)

That way, you will not be trying to pry this way and that, to get the top one in place. Just get it up against the ceiling, and then slip or pound the 2x in between the two.

Good idea, but this is on a mezzanine. The top of triangular wall is 19' above the concrete floor, and not really accessible by the forklift.

There are many situations, especially in remodeling, that call for "jungle framing". This might be one of them.

I can think of three or four different approaches but there are a lot of unanswered questions so I don't want to speculate.

One stick at a time and in not time you'd be done. There are only ten or eleven studs....

By the way, the pitch is: 12.3 rise and 16.1 run. Do some simple math (ratio and proportion) to get the difference in length. Without doing any figuring, I'd just use 12.2 inches if you were laying out on 16" centers. I'd start with my door king stud and go 16" from there.

FKA Blue (eyeddevil)

Edited 11/5/2007 9:48 pm ET by Jim_Allen

Biff,

If you just wanted the stud height difference all you have to do is create the top triangle and forget about the bottom part for now by doing this;

10'3" - 5'11" = 52"

[Inch] [Rise]

13'5 [Inch] [Run]

[Pitch] = 17.90° or 3-7/8/12 Pitch (Pitch angle of wall)

16[Inch] [Run] [Rise] = 5-3/16" (Stud Height Difference)

If you wanted to frame the wall with continuous studs you just keep doing this;

5'11 [Inch] [+] 5-3/16" = 6'4-3/16"

[=] 6'9-5/16"

[=] 7'2-1/2"

[=] 7'7-11/16"

[=] 8'13/16"

[=] 8'6"

[=] 8'11-3/16"

[=] 9'4-5/16"

[=] 9'9-1/2"

Assuming that your top and bottom plates are relatively straight lines, as drawn, here's how I do it.

Figure the number of studs you need. Let's say it's 8. Lay them down on the floor. Mark stud no. 1 (at the beginning of the row of studs) as the long stud. Mark stud no. 8 (at the end of the row) as the short stud. Connect the lines with a chalk line and cut on the line. Done. Perfectly cut and angled studs. (Also assumes equal spacing. Any oddballs for, e.g., windows, have to be individually measured & cut.)

Mike Hennessy

Pittsburgh, PA

PS: I just re-read your OP and noticed that the ends are not plumb. Plumb them first by installing a plumb starter stud next to them and frame your wall between the starters.

Edited 11/6/2007 6:18 am ET by MikeHennessy

So all the studs are sitting on their sides? The initial cut you make, then, doesn't go all the way through?

MUCH smoother sailing today. Thanks for the input. The second wall, on the other side of the barn, is going up twice as fast.

Working next to the edge of the mezzanine - which is the high side, the peak being 19' feet from the floor - keeps reminding me of the time when I fell off that mezzanine, snapped my pinky finger in half and and got knocked unconscious. What's funny is that I always had a fear of heights as a kid, got over it, but then it came back after I did that.

All done! I felt like a pimp, what with pre-cutting my studs, putting them on the mark, slapping them against the top-plate and - BAM! - plumb. Well, maybe a few hammer taps, but nothing unreasonable.I've still got to sheath them tomorrow.

Well, It's only ten studs, the floor is out of whack and the ceiling most likely is too. Put down the bottom plate, put up the top plate, layout the bottom plate, transfer the marks to the top plate with a 90 dollar laser plumb bob. There's 30 minutes. Take rough measurements for each stud, cut the top 1" longer than the rough measurement, then hold and mark each stud in place, cut and nail. Done in a couple of hours.Steve

I start with the longer studs and cut them to what I think they should be. If they are short, I eyeball the distance I have to add, cut a new one and use the short one for the next stud.Ten studs....five minutes per stud is generous....that makes this a one hour wall. FKA Blue (eyeddevil)

Hi Blue,I absolutely love and could not live without my laser plumb bob. It saves so much time. And I live by the adage if you can hold it up and mark it in place, do it.Steve

You just mark them while they are sitting on their sides, unless you have one of those BIG Makitas -- & I don't. You cut them as usual, but you can set the bevel on your saw (if it's big enough to make a difference) using the marked line as a guide.

Mike HennessyPittsburgh, PA