I would like some feed back on the use of a propane torch, for bending PVC pipe.

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

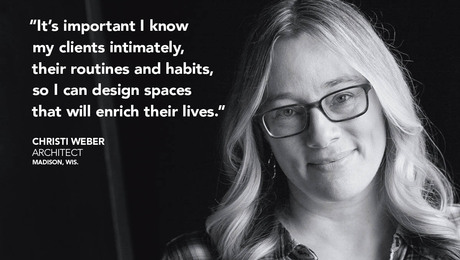

This thoughtful architect advocates for designing small, environmentally conscious spaces.

Featured Video

Video: Build a Fireplace, Brick by BrickHighlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Replies

A heat gun used carefully, or wrapping the section to be bent with towels and pouring boiling water across them the would probably work better than trying to warm the pipe with the flame of propane.

PVC softens up pretty easily.

I had to rehape a 1 1/2" piece of pvc conduit from 45 to about 20 deg (Had I known the actual need I would have bent a straight piece to 20). I used a heat gun and it worked great. BIL where I was working had one on a stand for doing heat shrink. Worked it around the area and blew it down through it a little. Like most things do not rush it.

Bob

We've done it a few times with a heat gun -- to get a 3" PVC into an existing CI stack.

But I was told it's not legal (code). Is that true?

********************************************************

"I tend to live in the past because most of my life is there."

-- Herb Caen (1916-1997)

Use a wide flame nozzle. Keep the flame moving. No need to get too close. Work in a confined are a out of the wind and off damp ground that soaks up the heat. A piece of plywood makes a handy work platform, keeps you and your work out of the mud, and it allows you to draw reference lines.

On a hot summer day you can speed the process along by laying the PVC in the sun. Out of the wind and on a dark surface improves the effect and helps in the winter, a bit.

Taping up both ends of the conduit with duct tape keeps the heat in and the confined air pressure helps prevent flattening.

Gloves, leather or cotton, a spray bottle with water and a few rags help in handling the hot conduit and freezing it in place when you have the shape you want.

I use a simple peizo-start propane head on a one pound bottle for small conduit. Best under 1" but I have worked 2" with this also.

I work the flame diagonally. Start above and to the left of the bend area and sweep in a quick wrist motion to below and to the right. This gives you maximum exposure to the pipe while keeping the stops, where the PVC will tend to burn, away from the conduit. At the same time rotating the conduit so all sides of the conduit are heated.

You know your concentrating to much heat, using too tight a tip, working too close or stopping on the PVC shows up as a burnt spot. Minor browning isn't an issue if the conduit is going underground. Don't brag about it. A seriously singed section could cause the inspector to demand you replace it. Of course melting or scorching that isn't just a cosmetic thing demands replacement. 'All work will be completed in a neat and workmanlike manner'.

Take your time and work for a distance on both sides of the bend area. Helps to use a sharpie, pencil if the conduit will be visible, to draw a ring around the pipe at the beginning and end of the area so you know where your at as the conduit spins.

Sometimes it helps, especially on offsets, to draw reference lines on the surface your working on so you can hold the softened pipe in place against it to get what you want as opposed to having to work a tape measure while keeping thing in position. Helps to have an extra set of hands on complicated bends and larger pipe. Otherwise I use my feet, knee, hands and, if I'm lucky and was thinking ahead, some pieces of wood and concrete blocks.

On commercial sites there are glycol filled heaters, heat blankets or electric ovens designed for bending PVC. Mostly, because I work mostly small jobs, I use a torch. A heat gun is about as good but power can be an issue. I have been known to stuff short and small diameter pipe up the tailpipe of my truck. Gives me a chance to heat up/ cool off, as the season and case may be, and listen to a little music as I get it to run a little faster, hotter.

I have also produced a tailpipe driven hot box out of water heater flue pipe. When I needed four similar pieces with a complicated bend. Worked well.

Do a few practice pieces in 1/2" PVC to get a feel for it. I try to set my help up with a ten foot stick cut into 3' sections and have them bend a couple of nineties and an offset on the last piece. On a slow day it makes for good training. They get the basics. I get a pipe bender that knows the ropes and the help seems to appreciate the time and effort.

A one pound standard elongated torch bottle lasts a long time. I keep a spare handy but ten or twelve nineties in 1/2" or about four in 2" sounds about right.