Roof Framing with Engineered Lumber

Tips from a custom framer make the engineered-lumber learning curve easier to negotiate.

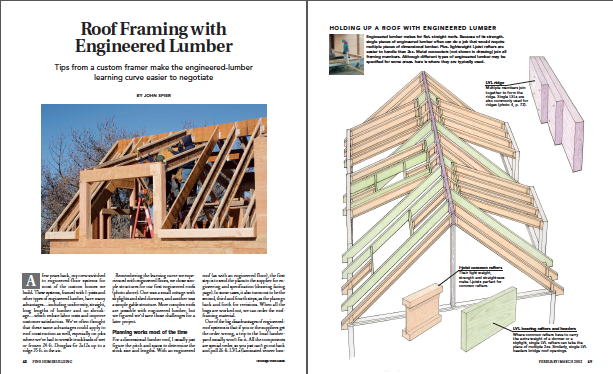

Synopsis: A builder explains how he uses different types of engineered lumber, including LVL ridges, bearing rafters and headers, and I-joist rafters, to frame the roofs of custom homes. Included are useful tips to facilitate working with these materials.

A few years back, my crew switched to engineered-floor systems for most of the custom homes we build. These systems, framed with I-joists and other types of engineered lumber, have many advantages — including uniformity, straight, long lengths of lumber and no shrinkage — which reduce labor costs and improve customer satisfaction. We’ve often thought that these same advantages could apply to roof construction as well, especially on jobs where we’ve had to wrestle truckloads of wet or frozen 24-ft. Douglas-fir 2x12s up to a ridge 35 ft. in the air.

Remembering the learning curve we experienced with engineered floors, we chose simple structures for our first engineered roofs. One was a small cottage with skylights and shed dormers, and another was a simple gable structure. More complex roofs are possible with engineered lumber, but we figured we’d save those challenges for a later project.

Planning works most of the time

For a dimensional-lumber roof, I usually just figure the pitch and spans to determine the stock size and lengths. With an engineered roof (as with an engineered floor), the first step is to send the plans to the supplier for engineering and specification. In some cases, it also turns out to be the second, third and fourth steps, as the plans go back and forth for revisions. When all the bugs are worked out, we can order the roof framing material.

One of the big disadvantages of engineered roof systems is that if you or the suppliers get the order wrong, a trip to the local lumberyard usually won’t fix it. All the components are special-order, so you just can’t go out back and pull 26-ft. LVLs (laminated veneer lumber) out of the rack. In our case, the local yard is a boat trip away.

The ridge and bearing rafters

Before the roof load arrives, we frame and stand the gable ends, ridge posts, knee walls and dormer walls. Framing the roof is then simply a matter of assembling the lumber and hardware.

One of the roofs that we built has a single LSL (laminated strand lumber) for the ridge. The other roof has three 26-ft. long LVLs for the ridge, which were set in place one piece at a time and then spiked together. The engineering specs provide a fastening schedule for assembling multiple structural members (such as an LVL ridge or header), and at least some hand-nailing usually is required to get them tight and to eliminate gaps.

For more photos, illustrations, and details, click the View PDF button below.

For more photos, illustrations, and details, click the View PDF button below.

From Fine Homebuilding #153

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Leather Tool Rig

Peel & Stick Underlayment

Roofing Gun