As builders of passive-solar homes in a severe climate, we combine heavily insulated concrete and stud walls with fixed glass windows on the south side for direct gain.

Large areas of insulated glass can be installed economically if the units are standard sizes and fixed directly to the building’s framework. We use tempered glass made for patio doors; they are available at reasonable cost and resist almost any form of abuse. If a unit must be replaced, it can be done easily using this form of installation.

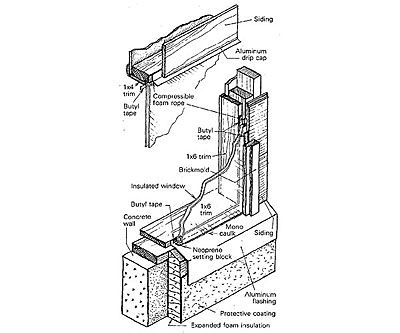

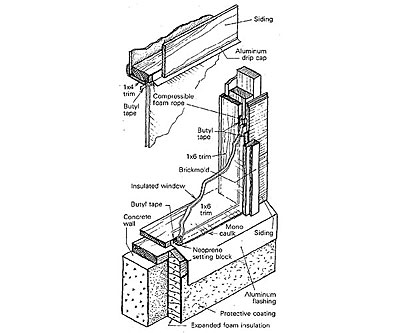

Frame the rough opening with a 1/2-in. gap at the top and sides to allow for expansion and framing irregularities. Cuprinol or copper naphthalate preservative on the interior trim will reduce the water damage from condensation,which is inevitable. A few coats of marine varnish will extend the life of the wooden sill.

Butyl tape greatly simplifies glazing. We use Butyl 440 tape from Tremco; it is a uniform bead of butyl caulk with a paper backing that prevents it from sticking to itself. It is packaged in coils and can be purchased at many hardware or paint stores. Automobile glass installers also use it. Leaving the protective paper layer on allows you to install the tape against the interior stops, check the window for fit, remove the paper and instantly secure the window. We place neoprene setting blocks under the window as it is installed to absorb expansion and contraction of the glass and frame. The blocks are site cut to the thickness of the window unit from 1/4-in. thick neoprene and are normally 1-1/4 in. long — usually two per panel. Then we use Tremco mono caulk to seal the base of the window. Compressible foam rope in. wide fills the spaces at the sides and top of the window and allows for expansion.

The aluminum drip cap at the top of the window overlaps the brickmold trim on both sides, minimizing exterior trim and further reducing weathering problems. As soon as the sun comes out, any drift of snow or ice at the bottom of the window slides off the aluminum flashing (preferably a dark color).

Tom Ashman, Wiarton, Ontario, CA

Click the "thumbs up" button above to vote for this tip. Help us choose Fine Homebuilding's top-10 window and door tips.

View Comments

Really appreciate this detailed how-to. I like the idea of being efficient in the materials required as well as the implied energy efficiency.