Masons are accustomed to speedy work with block, but working with aerated autoclaved concrete (AAC) can be slow going. You need special trowels and mortar, and AAC requires precise drilling for the threaded rod that connects the foundation with the top plate.

Hebel makes its ACC blocks from a mix of cement, lime, sand, gypsum, water and an expanding agent. It’s hardened in a mold and then steam-cured under pressure. One thing masons will like is the weight–far less than typical concrete blocks. Although the material is available in different densities and sizes, the block we used measures 8 in. by 8 in. by 24 in. and weighs 28 lb. It can be cut with a handsaw, but we rented a bandsaw from Hebel that made cutting the block easy.

Although a masonry crew’s first experience with the material can be discouraging, paying well helps. We pay $4.50 per block. This rate compares with $1.50 per standard concrete-masonry unit. Hebel block isn’t cheap to buy, either. Blocks come to about $4.50 each with shipping. The Pearsons’ AAC walls cost about $9,000. Although this amount is more than typical construction, finishing costs were lower. The exterior gets a single coat of stucco, and interior walls a single coat of a soft, high-gypsum-content plaster. These factors made AAC affordable for the first floor of the Pearson house. Costs are higher for scaffolding work, so we didn’t use Hebel block in the gable ends.

Hebel block starts just above grade

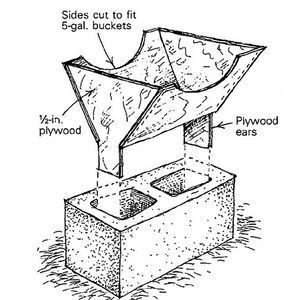

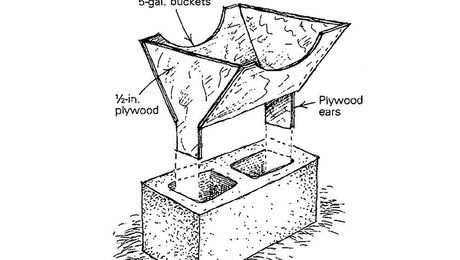

After pouring a concrete footing, we bring a standard concrete-block foundation up 10 in. to 12 in. above grade. Long 5/8-in. anchor bolts and couplers are set to the bottom of the first course of block, two or three per wall. The block is then filled with concrete. The first course of Hebel block is set in S-type cement mortar, but subsequent courses are set with a special thinset mortar provided by Hebel. Blocks are laid with no visible joint, so it is crucial that mortar be applied carefully. Hebel sells special trowels designed for the job.

As each course is set, blocks must be drilled precisely for threaded rod that eventually will run from the anchor bolts to the top plate. We drilled 2-1/4-in. holes to give ourselves plenty of wiggle room for the 5/8-in. rod. Each wall has two or three rods tying it to the foundation. At the top of the wall, we use a U-shaped Hebel block in which we pour a continuous concrete bond beam. Before the concrete bond beam is poured, we fill the holes for the rod with mortar.

Build bucks for doors and windows

We build door bucks from pressure-treated stock. We use construction adhesive and 6-in. nails provided by Hebel to anchor the bucks to the block as the walls are built around them. This sequencing allows us to control the size, placement, plumbness and squareness of all the door and window openings. We try to size windows so that they fit on even courses of block without having to cut a lot of small infill pieces.

Although you can order ACC door and window lintels, we prefer to pour our own bond beams in place. We used the U-shaped Hebel block for the form, and we reinforced each lintel with steel. The premade lintels are dangerously heavy to raise without the assistance of heavy equipment.

“So how do you wire this wonderful stuff?”

We’re asked that question often. It’s not that hard. Hebel will provide a router to cut channels in the walls for electrical conduit. But we think it’s easier to use a circular saw to slice grooves in block, then chunk out the waste with an old chisel or a screwdriver. Buy an inexpensive saw because the dust from one job probably will ruin it. We use a diamond-matrix blade for the cuts.

Before finishing ACC walls, we patch any irregularities with Hebel-block patch and use a Hebel toothed rasp to smooth the wall surfaces. Stucco is floated on the exterior walls to make a decorative, one-coat finish that needs no vapor barrier. We also plaster interior walls. Wire lath isn’t needed.

Photos: Kathleen Jardine and James Cameron; drawings: Scott Bricher

View Comments

Great idea. Thanks for sharing this article.

Good job you done here!

Thanks for sharing!

Great information here