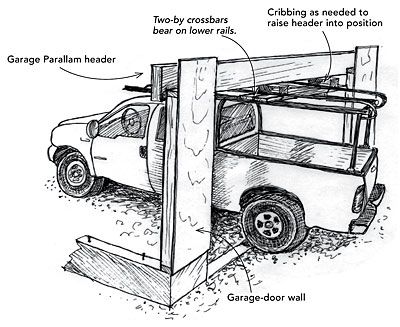

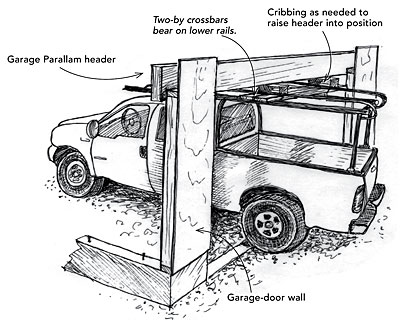

The Parallam beams used as headers atop Simpson garage-door walls are heavy. They are typically 31/2 in. wide by 16 in. deep by 22 ft. long. I don’t want to move one of these beams around any more than I have to. On my last job, I didn’t even take it off my truck’s lumber rack. Instead, I pulled the truck into the future garage-door opening, as shown in the drawing.

Next, I cut the header to length and rotated it 90° and onto the upper rail of the rack. Then I slid a couple of 2x6s onto the lower rail, directly under the beam. The 2xs support the cribbing necessary to raise the header to the desired height.

This process worked surprisingly well. A standard truck with a rack is just slightly lower in height than a standard 7-ft.-tall garage-door opening, so the beam doesn’t have far to go. Everything was centered—truck, cribbing, and beam—and because of the beam’s long overhang on each side of the rack, it’s easy for one person to lever it into

Keith Wilson, Mountain View, CA

Click the "thumbs up" button above to vote for this tip. Help us choose Fine Homebuilding's top-10 window and door tips.