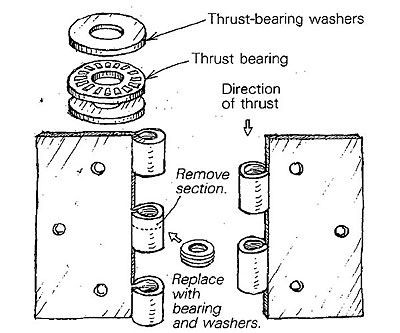

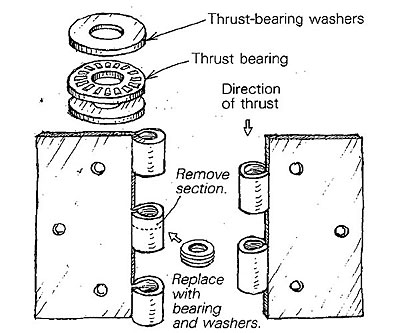

For me, the most .frustrating part of making and installing a heavy, handmade entry door has been finding the right hinges. Even with a good set of heavy butts, the hinge barrels begin to grind down after a while. Soon, the door sags so much that the bottom rail drags on the threshold. A solution to this problem became obvious when I discovered thrust bearings at a bearing-supply outlet recently. Thrust bearings (see drawing) are simply a set of needle bearings captured in a circular metal collar. They come in a variety of sizes. These bearings are used in conjunction with a pair of thrust-bearing washers, which are machined to close tolerances.

To fix the door, I used a hacksaw to cut a section out of the appropriate barrel of each hinge leaf, replaced the section with the thrust bearing and the washers, then reinstalled the hinge pins, as shown. My hinges show virtually no wear after six years of use.

Clint Lewis, Woodland Park, CO

Click the "thumbs up" button above to vote for this tip. Help us choose Fine Homebuilding's top-10 window and door tips.

View Comments

I don't think this is a prudent method for providing a wear resistant, smooth operating hinge. Good quality ball bearing hinges are readily available;why reinvent the wheel? When you cut away a section of the original hinge the structural integrity of the hinge is immediately compromised. The hinge is specifically designed to support the weight of the door, why alter it. I think the effort is misdirected.

nice info

very useful Information.