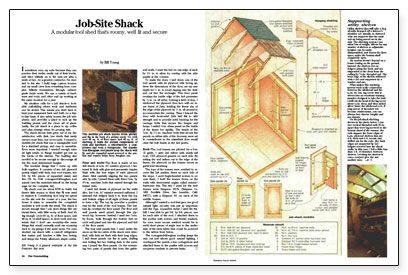

Synopsis: A builder shares his plans for building a tool shed from modular components and roof trusses that can be assembled quickly and moved from the site when the job is over. Translucent roof panels let in the light.

I sometimes envy my subs because they can practice their trades neatly out of their trucks, and drive blithely on to the next job after a week or two. As a general contractor, I’m married to the site. I build large custom houses, and my small crew does everything from complex hillside foundations through cabinet-grade finish work. We use a variety of hardware and tools, and often end up working at the same location for a year.

My situation calls for a job shack — a lockable outbuilding where tools and hardware can be stored. This means you don’t have to haul your equipment back and forth on a day-to-day basis. It also safely houses the job telephone, and provides a place to tack up the building permit and the clean set of plans. Lastly, the job shack is a place to sip coffee and plan strategy when it’s pouring rain.

The shack shown here grew out of my dissatisfaction with dark, low sheds that rarely survive more than one or two jobs. I wanted a durable job shack that was a manageable load for a standard pickup, and easy to assemble. Even more important, I wanted enough natural light inside so things wouldn’t get lost on the backs of the shelves. The building also needed to be secure enough to discourage all but the most determined burglar.

The modular design that I came up with bolts together. It consists of ten 4×8 plywood panels edged with 4x4s, four roof trusses, two 5-ft. by 8-ft. pieces of expanded metal, and five 2-ft. by 10-ft. corrugated-fiberglass roof panels.

My shack cost me about $700 to build, but there’s little reason to think that I’ll ever need to replace it. Considering how long we spend on the site over the course of a year, the two hours it takes to assemble the completed modules is well worth the result. The shack is secure enough that I can store things like my transit there, with little worry of theft. And it’s big enough (over 60 sq. ft. of floor space, and 48 sq. ft. of shelf space) to store tools and materials that I don’t use everyday — the same things that would normally send me scurrying back to my garage if the need arose. I’ve even stocked my shack with a cast-off refrigerator that makes pail lunches a little less boring, and keeps the Friday afternoon staple colder.

Floor and walls

The floor is made of two 4×8 sheets of 3/4-in. AC exterior plywood. I fastened fir 4x4s with glue and pneumatic staples flush with the four edges of each plywood sheet. After carefully aligning the two panels side by side, I joined them with three 5/8-in. by 8½-in. machine bolts that extend through the butted 4x4s.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Peel & Stick Underlayment

Ladder Stand Off

Flashing Boot Repair