I have a sturdy fiberglass shell on the bed of my pickup truck. While it’s handy for storing tools and many supplies, I needed a rack on top to carry oversize cargo. I come from a nautical background, so I wanted my new rack to reflect my long-standing interest in finely crafted boats. This led me to the local boat-supply shop, where I found a good selection of teak handrails. They come in various lengths, depending on the number of loops in the handrail. Each loop is about 14 in. long. The rails I selected are the four-loop variety.

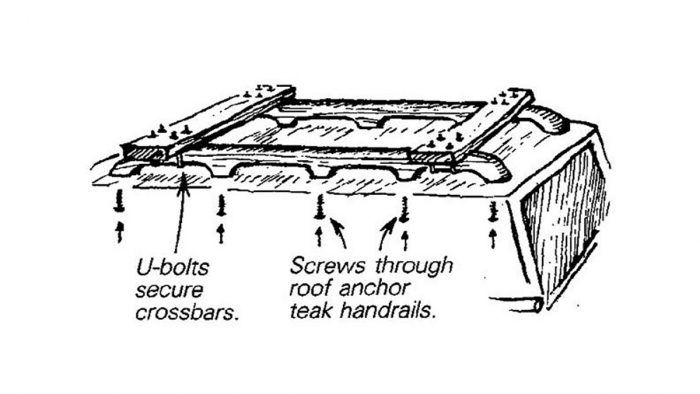

I attached the handrails to the roof by running screws with 5/8-in. washers through the fiberglass roof from inside the shell. The crossbars are pressure-treated 2x6s, secured to the handrails with a pair of U-bolts at each connection. Now I’ve got a sturdy, versatile roof rack that looks sharp, with lots of places to anchor a line.

Chuck Keller, Marblehead, MA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #41

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

8067 All-Weather Flashing Tape

Affordable IR Camera

View Comments

I would never dispute the utility of a roof rack for overlength items, however the 1-2 mpg hit on fuel mileage adds up over time. Since I rarely used the roof rack that came with my cap, I removed it and used stainless steel round head bolts, sealing washers & wing nuts (on the interior) to fill the holes. If I ever need to reinstall the rack it would be a simple matter.

In this case, I would strongly recommend through bolts rather than screws from the inside. Safety is essential and I wouldn't trust the wood to not split along the grain when carrying a load with a lot of wind resistance.

These tips about rigging pickup trucks to carry tools or materials raise a question: Why use a pickup truck at all? My experience is that contractors who come on the job with a van have their whole shop with them and don’t have to go fetch that missing item. And a bunch of sheets of plywood and sheetrock will fit in as well - all out of the rain. Sure, van users have shelves and racks built in but it’s all accessible. It seems to me that there’s a pickup truck paradigm that construction people think they have to live out - or at least that’s what the car companies have been very clever at pushing so they can realize the high margins on pickup trucks.

I'd countersink the ends of the U-bolts and their nuts so you have a smooth top of rack to slide material on or you'll gouge your plywood, sheetrock, etc. Assuming this is not already the way you have it, and the illustration just looks like they're protruding.