Laying up Stone Veneer

A masonry facade is an economical way to give wood-frame walls the look of solid stone.

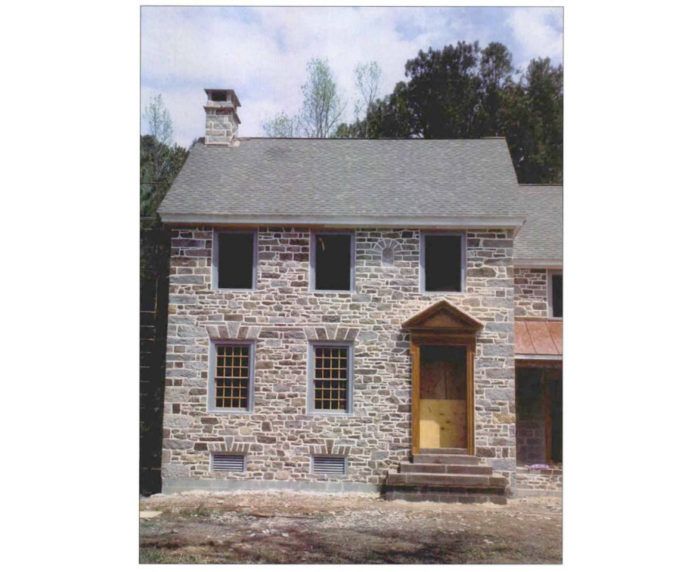

Synopsis: A Pennsylvania stone mason describes a project in which he applied stone veneer to a wood framed building. He discusses a number of important details, including the reinforcement of the foundation wall to carry the extra weight of the stone and the use of keystone lintels over the windows. A good primer on the subject.

On a trip through Bucks County, Pennsylvania, in the early 1980s, Brenda and Buddy Williams noticed a stone house, that soon became something of an obsession. During subsequent visits over the next several years, they studied the house, which is called Burgess Lea. Built in 1689, the house is an exquisite example of early Quaker architecture, and it had been brought back to museumlike quality by its owner.

I had become the resident stonemason at Burgess Lea, working there every year on jobs that took from a few weeks to a month or two. In 1989, the Williamses approached me with their plans to build a house in Mississippi patterned after Burgess Lea. They asked for my help in understanding the stone details of the house and how they could reproduce them economically. Fortunately, I had plenty of experience in reproducing period stonework in 6-in. and 8-in. veneers. Because of the huge economy of labor and materials in veneer construction, not to mention the insulating advantages of frame construction, the Williamses decided that veneer construction was the most reasonable way to go. An 8-in. veneer on a 2×6 frame could approach the 18-in. thick stone walls of Burgess Lea.

After showing me their blueprints and thanking me for my input, they prepared to leave. On her way out, Brenda turned to me and asked if I would consider doing the stonework. I thought she was joking, but two years later, I was on my way to Mississippi.

Salvaged stone doesn’t go as far

The sandstone of the Williamses’ house was to match that of Burgess Lea’s. Because freshly quarried stone would not have matched the stones used on Burgess Lea, we used salvaged stone from Pennsylvania. As I collected the stone I’d need for the job, I considered its color, size and shape. An old barn, a dismantled prison, stone quarries and fields all yielded parts of the new house.

A ton of stone will cover 25 sq. ft. to 30 sq. ft. in an 8-in. veneer. Most quarries that sell building stone cut or split the pieces into 4-in., 6-in., or 8-in. widths for veneers. These stones don’t produce much waste, so 30 sq. ft. per ton should be adequate for an 8-in. veneer. But because salvaged stone must be trimmed to width, it produces more waste, and I counted on covering only 25 sq. ft. per ton. My job was to veneer the facade of the main house, the center addition and the foundation around the kitchen wing. The rest of the siding would be wood. With a little more than 1,100 sq. ft. of stonework, I needed approximately 45 tons of stone.

For more photos, illustrations, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

100-ft. Tape Measure

Plate Level

Original Speed Square