Installing Manufactured-Stone Veneer

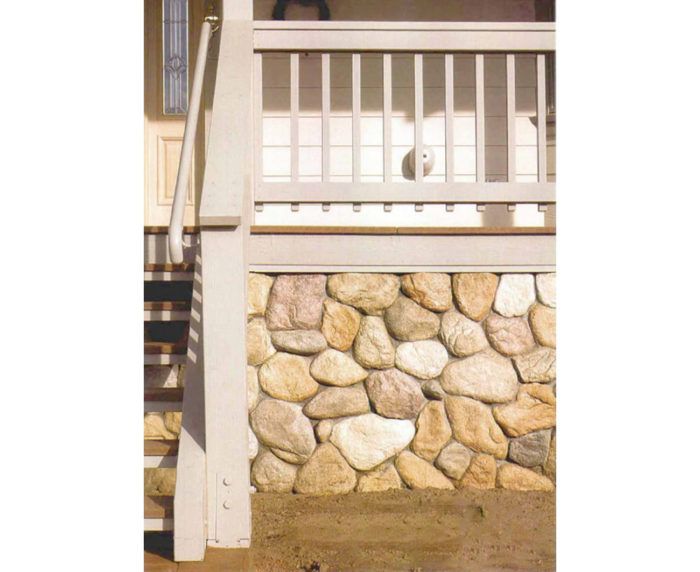

Made from cast concrete, so-called phony stone is good looking, affordable and easy to work with, but best of all, gravity is not required.

Synopsis: This article explains how manufactured stone veneer, which is really cast concrete colored to look like natural stone, is applied to a substrate of metal lath with mortar. The author describes the different versions of this product on the market and includes a list of suppliers.

Years ago, I was driving down the road and happened to glance over at a construction site. Two masons perched on scaffolding 25 ft. in the air were setting stone on the outside of a chimney. They had completed about one jagged foot of stone all around the top of the chimney, working down instead of up.

I couldn’t believe my eyes. Ordinarily, I’d stop to find out what was going on. But I was too stunned to react, and I just kept driving. Later, I discovered their secret: They were installing manufactured stone.

Manufactured stone looks like the real thing

Most people have trouble discerning manufactured stone from natural stone, even up close. Even experienced masons can have difficulty distinguishing the two. Phony stone, as some masons disparagingly call it, looks like the genuine article in both shape and color.

So what’s not to like about the stuff? First, lightweight manufactured stone lacks the heft of natural stone. And to the experienced hand and eye, it doesn’t have the same solid feel or depth of color as rock that has formed over millions of years. It’s also applied more like tilework than stonework.

Natural stone has color throughout each piece, but manufactured stone’s beauty is skin deep. The color is just on the outer surface, which makes cleanup a bit more problematic, something I’ll get to later.

But manufactured stone does have advantages, the biggest of which is that it can be installed from the top down, seemingly in defiance of gravity. Most manufacturers’ instructions state that it can be installed in either direction, but working in the reverse of standard masonry logic makes cleanup easier because you are not dropping mortar all over the completed work.

Compared with natural stone, manufactured stone cuts more easily and more predictably. Made from cast concrete, manufactured stone has an even consistency in each piece, making it easy to shape and fit.

Manufactured stone’s biggest advantage is cost. The clients on this project wanted natural river stone for both an inside hearth and for the veneer on the foundation and chimney outside. When the price came in more than they wanted to spend, they decided to use manufactured stone outside, which cut the cost in half. The money they saved let them use the real McCoy inside where the stone would be seen much more closely. Manufactured stone comes in a variety of shapes and colors, so it was no problem duplicating the river-washed look of the Canadian stone they had chosen.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Smart String Line

100-ft. Tape Measure

Plate Level