Floating a Shelf

Use steel brackets with mounting rods to level a shelf and lock it in place.

I want to add some floating shelves in my living room, but I don’t quite know how to tackle them. How do you go about creating a stout attachment?

—Hal via email

Lavrans Mathiesen, owner of Seattle Mobile Builders in Seattle, replies: Floating shelves give me nightmares. I imagine them falling off or sagging, and that special vase slowly making its way over the abyss. Nonetheless, they are attractive little bits of magic hovering without obvious support.

There are a variety of stock solutions. Most seem to be face-mounted, with brackets that attach to the faces of the wall studs and rods that fit into holes drilled into the back of the shelf. This is my least favorite option; the small amount of anchoring structure, often installed over drywall, feeds right into my overly active imagination.

Carpenters have come up with a variety of their own solutions that share the same basic idea of the stock options. Two examples are 1/2-in. pipe glued in a hole in the face of a stud, and long, 1/2-in. lags screwed into the studs so several inches stand out from the wall, with the heads cut off.

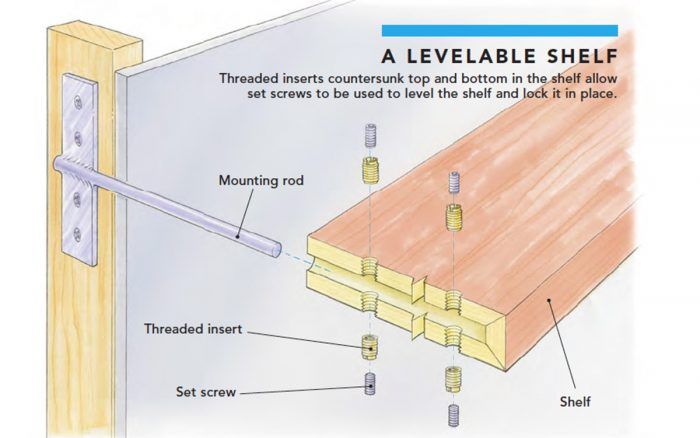

My favorite method is to attach a steel bracket to the sides of the studs, which requires either getting there before drywall or pulling off some drywall and then patching. That little bit of pain makes for the strongest installation—one that can support anything from a small knickknack shelf to a floating vanity.

A “T” can be made by any welder using 1/4-in. flat stock for the vertical piece that screws to the side of the stud. The horizontal piece can be anything from 1/2-in. rod for a small shelf to 4-in. angle-iron that can support a vanity. The heavier the shelf or suspended unit, the longer I like the vertical member to be. This resists the torque from the finished piece, helping to keep it perpendicular to the wall. In the case of large or heavy installs, it can help keep the stud from bending under load.

I often see floating shelves installed by putting adhesive into the holes before sliding it onto the mounting hardware. This makes the installation permanent, and any problems later can be difficult or impossible to correct without destroying the shelf. I prefer to drill holes for the mounting rod from the back of the shelf. Then, from above and below, I countersink threaded inserts in the shelf that take set screws to both level and hold the shelf in place.

Drawing: Dan Thornton

From Fine Homebuilding #292

More about floating shelves:

Floating Shelves Made Strong and Simple – These grain-matched, mitered floating shelves slide onto a cleat for easy installation and a clean, modern look.

Strong Floating Shelves – To make a floating shelf, the best way is to start from the framing.