My galpal and i are trying to get her property divided. A well driller came in last week to find water for the new parcel, but it is clayey…not uncommon in that area. We need to pump it for a couple weeks, see whether it clears or we get the drilling rig back in and head for China.

This all happened much more quickly than anticipated, and the pump installer can shoehorn this job of installing the pump tomorrow afternoon (!) and needs power. I found a subpanel in my friend’s small barn 40′ from the well head, with 10/2/G coming from the panel in the rental house about 125′ away feeding (2) 110V. circuits on 10-amp breakers. I asked the pump installer if i ran some 10/2 from there 40′ to the well-head, if that would get us through until i could (re)do the job properly. He thought it would.

I’d like to fix this properly, have the controls and subpanel in the barn, but have the right size wire and panel with breakers for the pump plus a circuit or two for outlets and lights. I know enough about voltage drops and AL v. CU wire to know i don’t know enough, but i’d like to do all the work possible before we have to rustle up an honest-to-God electrician to do the connections, as i don’t feel comfortable doing the latter on rental property on someone else’s land that will soon be sold.

So the big Q: What would you recommendation for a subpanel for this use, and what is the proper size wire to feed it from 125′ away?

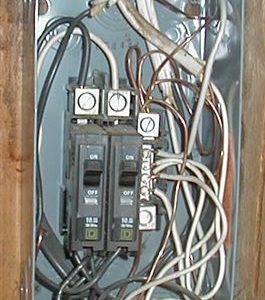

Pix of present mess attached.

Replies

I am lost in this, but are you asking about the proper size of a sub-panel in the barn to supply the barn and the well?

Well what are the loads in the barn?

What size pump? What are the electrical specs on the pump?

I need a subpanel to handle the pump on a 220V. circuit (not sure what size the pump guy will install, but my WAG based on the level my own pump is set at is 1/2 hp) and a couple 100V. circuits for the barn lights and 2-3 outlets for small tools or whatever. The present subpanel is rated at 70 amp on the cover, but there are only two breakers. I obviously need more breakers, but i'm not sure how to 1) specify what sort of subpanel i need and 2) what size wire i would need to feed the requirements i've outlined from 125' away at the main panel. (Poop! I was trying so hard to be clear the first time! <G>)

I think that min size of panel that you will find is 60 amps.A 60 (or 80) amp 6 or 8 position panel would be what you want.Feeding it with 60 amps would be nice if they ever wanted to run a welder in the barn.But you could feed it from a 30 amp breaker and still have plenty of power. Don't have time to look up the wire size.

Bill,

Did you have time to look at the pix. There is no neutral (egc pretending to be one), way too many circuits apear in ths box. Looks like they can have 220 (one double pole) or 110 ( redirect white to neutral at svc and use panel with main bus and two breakers) but not both.

Looks like only safe way would be to abandon the 110's, put in double pole appropriate for the pump if load and drop calcs work out. Then do it right later as OP said.

Bob

note: this is a question, not advice.

Edited 8/16/2006 10:56 am ET by rasconc

No, I did not look at it that close.I might have misread it, but I was thinking that she was looking to get the stuff so that it could be replaced right away.But if the idea is to just run a temp line to test the pump then you are right, replace replace with a double pole breaker and just run a line for the well.If there is no metallic paths back to the supplying panel then this can be done as a service entrance with neutral bonded to the ground. But in either case a ground electrode (ground rods) are needed.May not be too many circuits. QO breakers are speced to have one or TWO wires on it. But I count 5 neutrals but I don't knwo where they come from. It appears that there are 3 load cabels at the top. And the supply and one load cable at the bottom.But I doubt that the large lug is speced to hold 5 EGC connects.Also there are no romex connectors where then enter the box.

One breaker has three 110 circuit wires stuffed in it and the other has a couple circuits on it, but some of the circuits feed only one light or one outlet. In any case, all those circuits are being abandoned while we give all that power to the pump temporarily. Hmm....looks like i'll be reading the thread on grounds, too...

I'm headin out to work, but if you feel energetic.............

2 wire = 2K x L x I / Cm

K = 12.9 for copper,

L = length,

I = amps,

Cm = Circular mil ...for 10 ga, use 10,380 ?? or 10,000

nec wants <3% voltage drop and this should give you a ref.

.

.

.

.Wer ist jetzt der Idiot

?

Edited 8/16/2006 6:30 am by maddog3

If i let L=125 for total length and I=80 amps, then the formula gives me:2(12.9) x 125 x 80/10000 = 25.8, a number i confess i have no idea what to do with.

just walked in the door,"a number i confess i have no idea what to do with."I did not check your math but,

that is the number of volts that will be "dropped " from the measured volts at the service......so if you use a meter and measure something like 225 volts to start with, then measure it at the barn sub, you will see a 25.8volt difference or something very close to 200 volts.... which exceeds the 3% NEC rule.[ which is in this example can not exceed 6.75volts ] 3% of 225and also is too low to operate the pumpalso, don't forget to add the distance to the pump !

.....it is possible that you may need every bit of voltage possible AT the pump since the thing may go down a additional 100' or more......So, after I checked it looks like you could use #6 to the barn as a new 40amp feed and then #12 to the pump on a smaller breaker neither easy....or cheap .

.

.

.Wer ist jetzt der Idiot

?

here are the circular mils (cm) for other wire sizes, if you want them..#12........6530#10........10380 ...............it used to be 10,000 #8..........16510#6..........26240#4..........41740#3..........52620.

.

.

.Wer ist jetzt der Idiot

?

I used to go through the formulas to calculate voltage drops, but these days I use one of the many online calculators that are available. Just google on 'voltage drop calculator' and you'll find a bunch of them. This is the first one that came up just now when I did a search: http://www.csgnetwork.com/voltagedropcalc.html

oh sure,....make it easy for her.there was an electrician website that had a good one but it is now gone.

.

.

.Wer ist jetzt der Idiot

?

"oh sure,....make it easy for her.

there was an electrician website that had a good one but it is now gone"

I used to use that electrician.com website all the time, I wish I knew what happened to it. They had a bunch of useful calculators and reference lists.

yeah, electrician.com...looks like someone glommed onto the domain name. that's too bad, that guy did have a nice site. I read somewhere that he was having hacker problems, maybe he got fed up.

.

.

.Wer ist jetzt der Idiot

?

Stuart, i was just on that site when you posted! I'd googled various terms last night, but i only recently remembered about mortgage calculators, typed the word "calculator" into my search, and presto! It works!

Thanks to ALL you guys! I think i might have a plan now and no, i will NOT bury any styrofoam pellets...they are much too good with ranch dressing to waste like that.

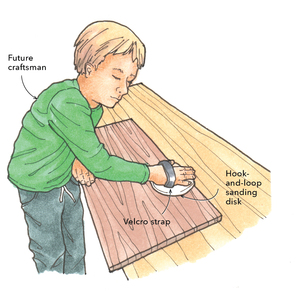

View Image

10 AWG is 1 ohm per 1000 ft .... (anybody doing elec work should be able to remember that number in their head, basic starting point for AWG wire comparisons).

Anyway, 125 + 40 = 165 ft, loop of 330 ft, so R= 0.33 ohms. 240 V 1/2 HP motor is about 3.5 A after PF, etc taken into account, so that's a voltage drop of only a volt or so, thus pump should be ok even up to a 1 HP motor. The QO series of breakers (single QO shown in pix) do come in dual breakers for one space, which would get you 4 breakers and get you by till things get re-wired correctly. The box as is looks to have only 2 spaces, intended only for a main feeder breaker, not for use as distribution panel.

As others said, do it right later. If worried about safety now, put all GFCI outlets on all wires coming from the barn panel.

Some items that are not correct as visible on the pix. The internal box pix does not even show black tape on the white wire coming out of the 10/2 UF cable. Looks like the ground wire is feeding the white wires for the barn 120 V circuits which works, but not per code and on the unsafe side.

No sign of a separate ground at the barn but that in the pix, or grounding conductor wire coming into the box, indicating not per code.

The barn needs a separate grounding system (you could run a bare 10 AWG from the well casing) and could then be rewired per code without having to run a new 125 ft cable from the house.

<<without having to run a new 125 ft cable from the house>>Let me double check on this: I can leave the present 10/2/G wire to feed a 60-80 amp subpanel, even if it is changed to a double pole breaker for the pump and two 110 circuits? It could be that easy, simple, and inexpensive??????If i can find the half-space breakers, would it be code or advisable to go ahead and use this present box with those breakers installed instead, in a permanent fashion? (Or until the next owners decide if they need to upgrade.)Thanks for the idea of grounding to the well casing. I wouldn't likely have thought of that.Heck, i think i might do this all myself...i can fix all the circuit consolidation, clamping, and color-code issues. It won't be as pretty as all new materials...but what i'm looking for is Safe and Serviceable.

Let me double check on this: I can leave the present 10/2/G wire to feed a 60-80 amp subpanel, even if it is changed to a double pole breaker for the pump and two 110 circuits?

There needs to be a 30A breaker inthe house feeding the 10/2 wg UF wire, if there is no 30 A breaker there, it HAS to be added, very unsafe now if not, add one there before doing anything else (would not have mentioed it but for all the other egregious items seen in the photo). The 70A subpanel rating is relatively meaningless, it is only as 'big' as the feeding circuit (10 AWG). You would not be able to have more than 6 breakers anyway without a main breaker or without running a 4 wire cable from the house.

It could be that easy, simple, and inexpensive??????

Well, maybe not that simple, as there are lots of details to fix, see your last paragraph. You need to shut the breaker off inthe house and pull all the wires out of the box for one thing to start with, etc.

If i can find the half-space breakers, would it be code or advisable to go ahead and use this present box with those breakers installed instead, in a permanent fashion? (Or until the next owners decide if they need to upgrade.)

I have not kept up on the lst few renditions of the code, but yes (obviously, with all the other items corrected)

Thanks for the idea of grounding to the well casing. I wouldn't likely have thought of that.

That's probaly the best ground on the place. Note: One interpretation of NEC is that the grounding conductor wire from the well casing to the case of the panel in the barn needs to be 8 AWG (minimum for anything smaller than #2) , not just 10 AWG, maybe Bill can comment on that.

Heck, i think i might do this all myself...i can fix all the circuit consolidation, clamping, and color-code issues. It won't be as pretty as all new materials...but what i'm looking for is Safe and Serviceable.

clamping - dont forget to put plugs in the big empty holes after you relocate the other wires to smaller holes and clamps.

Only 2 wires to each QO (now 3), yu need to pigtail a wire nut as needed.

Dont forget to put a disconnect in the well house - does not need to be another C/B, but you need to be able to disconect the motor without going 40 ft away.

The pump man got hung up today and couldn't make it, so i have some more time to research. I found a table in my own pump info that says one can go up to 1020 feet with #10 cable on a 2- or 3-wire 1/2 hp pump at 230V, one-way. If i put nothing else on that circuit, it would apparently be fine, but it might not be prudent to let the wacko renters have an outlet off that circuit as well.I should be able to get inside the house tomorrow to check the size of the breaker on the 10/2 cable to the barn. I understand there are still some open spaces in the main panel, so running circuits from home base to the barn for lights and outlets might be simpler that wiring in a new 60 amp. subpanel, and running #4 wire to it. Any comments on this new scheme?

first, your pump info is good to have and will work....just check at the mains to be sure you have the volts ! you should not lose more 3 volts at the well head at that amperage........and you are good to goyour other idea for the barn sounds good too. ! Bye.

.

.

.Wer ist jetzt der Idiot

?

"If i can find the half-space breakers, would it be code or advisable to go ahead and use this present box with those breakers installed instead, in a permanent fashion? (Or until the next owners decide if they need to upgrade.)"You can only use it if the panel allows. It will spec how many postions and poles.If it is silent on that then it was before that that rule and you can use them.However, they won't work for this application.What you need is QUAD breaker. That is a set of two tamdem breakers with the center 2 tied together for a 2 pole, 240 breaker and then 2 120 volt breakers on the outside.

Bill, thanks for the follow-up. I stopped this A.M. into the little hardware store in the closest hamlet to see what they might have. I found a Square D 20-30-30-20 quad breaker (center two breakers tied tog) today. I didn't know what it was called and the clerks had less of a clue than i, but it made sense to me so i bought it. Unfortunately, the existing breakers are a different style, meaning the new one wouldn't fit and so i returned it.According to my newest friend, the Wire Size Calculator, i would need 4/0 wire from the house to a 60-amp subpanel in the barn. I figured out the cost of materials as $350 to buy 4/0 wire and a quad breaker (if i could find the older style) as opposed to $200 to buy a 250' roll of 10/2 and two more breakers to go in the panel in the house to supply two circuits to the barn for outlets and lighting. (The present mess in the subpanel can easily be streamlined to two circuits.) The good news is, i just got word that there's a 30 amp breaker on the existing 10/2 line to the barn. Hallelujah, one more thing not to fix!

..actually #10 stranded is 1.24 ohms per 1000....

.

.

.Wer ist jetzt der Idiot

?

Edited 8/16/2006 6:10 pm by maddog3

Please supply a reference for the 1.24 ohm/kft for 10 AWG stranded, want to make sure I never buy from that source<G> (1.024??)

Some very fine stranding like 105/30 can be as high as 1.1 ohms/Kft, never seen 1.24 for 10 AWG.

well , I got it out of the 2005 NEC

Chap. 9

Table 8

pg. 70-635of course that's at 75 C.

.

.

.Wer ist jetzt der Idiot

?

OK, thanks.

Would be interesting to see the backfill that would let underground UF 10 AWG get to 75 C!

(note: SG: dont backfill your trench with old styrofoam pellets.)

yes, that would be very interesting.:).

.

.

.Wer ist jetzt der Idiot

?