Hi,

I ran across this technique for building well insulated walls at the Univ of Fairbanks Extension, was wondering what you think if it??

The link is: http://www.uaf.edu/ces/publications/freepubs/EEM-00954.pdf

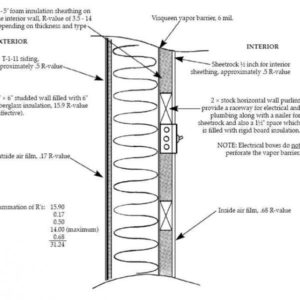

I tried to attach a picture with the cross section, but not sure if I succeeded.

The construction is basically a fairly normal 2X6 wall with fiberglass insulation. On the inside they install horizontal 2 inch thick purlins, with the space between the purlins filled with 2 inch thick polyisocyanurate with the alum foil face, then sheetrock inside attached to the purlins.

The seems to almost eliminate thermal bridging by the studs, and because of the very high R rating of the 2 inch polyiso (R7 per inch)

it gives a very high total R value for the wall — Something like R35.

I remember seeing somewhat similar schemes discussed here before, but don’t remember any that used the high R vlaue polyiso insulation.

Does this seem like a good scheme?

Gary

www.BuildItSolar.com

Replies

do a search for " Mooney Wall "... and no , the wall with fiberglass in it sucks, i mean ... why bother ?

hi, or you may just try to search simply "polyiso" in any folder, but more specifically in the heating and insulation folder... I've been doing LOTS of reading amongst these results... you'll find plenty of information... seems to be the thing to do... lots of agreement on the subject... with mongo apparantly the resident expert on the matter.... I hope you have as much luck as I do... still in the planning stage on my end... will be jumping in very soon.... we can all prey to the polyiso gods together...lol

I am doing a similar wall detail on my own house this spring. The difference to the wall you mentioned however, is that I am doing the rigid on the outside of of the wall. In fact, the APA has approved up to 1" of rigid to the outside of the stud while maintaining rack standards. What I have not decided is whether I will install it to the stud, then shething or sheathing first, then rigid. Hardi allows either of these as long as the sheathing is 7/16". while this detail I am considering is less rigid insulation thickness than you are considering, there is a TOTAL thermal bridge break by doing it continious, as opposed to between horizontal strapping.

Dave

Hi,I guess the thing that really appealed to me was the use of the 2 inches of polyiso at R7 per inch -- that a lot of R value in not much thickness. The reduction in thermal bridging also seem significant. It seems like the thermally brided area would go down from about 7% to less than 1%.On your rigid insulation to the outside, after looking at the APA pictures of Katrina damage, I think I would go for nailing the sheathing to the studs with the insulation board outside. It seems like you want the best shear connection bewteen the studs and the sheathing that you can get?Gary

http://www.BuildItSolar.com

there are lots of great combinations of ideas. I can't tell you how many times that I have told myself, "OK, that's what I am going with..." only to change the next day, and I am a (commercial) builder! for me, the budget will determine some of the details. Don't forget the roof, either. Many opinions are that's where you want to concentrate resources and R-vaule if you have to decide between the two. I am making an effort at both knowing that adding to the attic is easier than adding to the walls once constructed. windows also fall into this category. my current house walls are full masonry construction so I have learned a lot about thermal mass and bridging.

Dave

boulderbuilder.

Please read About SIP's more eficent cheaper, older technology and stronger as well!

I know about SIPS, in fact I have a Porter Sips brochure in front of me right now. I am leaving the outside four walls of my house standing and going up from there. Mixing construction methods is not a good idea for my own house. I have nothing against them and I like the technology. SIPS are kind of like Hybrid cars in my mind: sort of novel but not for me currently. There are so many other ways to make homes more efficient, good design and qualtiy construction methods are two that I am focusing on. Having an R-60 roof and R-45 walls are great, but when they are next to R-5 doors and windows there effectiveness is compromised.

Dave

boulderbuilder,

My old stick built house had very carefully insulated walls done to the highest standards of their day..

It cost me over $500.00 a month in Jan. & Dec. to heat. I had a digital thermometer and could ceck the temp of anyplace on the wall. One 0 degree day The outer walls were 49 and 53 degrees. the 49 was where a stud was and the 53 was where the insulation was..

every 16 inches there was a space of an inch and a half where it was 4 degrees colder..

Studs have an R value of about 2 anotherwords effectively no insulation..

so if you put no studs in the wall you gain in energy conservation..

I paid $3.00 a sq.ft for panels (six inch) and $3.80 for 10 inch panels..

If you use nothing but SIP's for the outer walls you will spend no more, build much faster and save on energy..

A large part of controling heat losss is controling convection and infiltration. FG batts suck at both. Then this detail has breaks in the foam panels at each and every purlin, making it hard to control the infiltration and convection there again.

You could increase the performance of that wall by doing the following -

use 1" instead of 2" foam - or even 1-1/2" but keep it continuous, tape the seams, and then run 3/4" strapping/furring over it as purlins, eliminating the gapping.

Use dens blown cellulose or FG BIBs in the cavity

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

There is no sense doing all that work if you are going to use junk windows. That is your weekest link for R-value.

or if you forget to insulate the rims or cielings - that all goes without saying. I was answering the question about good walls. You disagree with my answer? Go ahead - it's an area with lots of opinions

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

It seems like a good way to get a higher R-value. The builder that I had worked for in the past would use 1/2 or 1" foam on top of the osb which would elimate thermal bridging. I think any attempt beyond the standard 2 by 4 wall with fiberglass is a good step in the right direction. Btw using the 2 by 4 or 6 perlins may help to keep the walls straighter, and if you shot foam in the walls it would be one stout wall.

Piffan,

or you can stop taking a band-aide approach to energy and look at SIP's

SIPs have their place and I have a three inch stack of paper on them right near my left elbow 'cause that might be my next house design - but I was under the impression this guy already has some walls framed up - maybe I'm confusing him with another thread on this subject...

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Gary,

Wow!

the lengths you guys go to to avoid SIP's !

I will take any SIP wall againts any of the so called super insulated walls and in any heads up testing the same thickness of a SIP will result in greater energy savings..

You are aware of SIP's aren't you?

It stands for Structural insulted panel and has beeen around for many decades!

Just walk into anyplace with a freezer other than the stainless steel cldding you are looking at SIP's .

Cheaper than any stick built wall and yet 200% stronger!