Can we flash our insert windows without removing them? I think not…

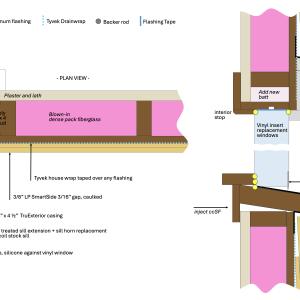

For what it’s worth I’ve continued to noodle this in the days since I first posted it. I got some help from a few experts. Looks like we really need to remove the windows to flash properly. Bonus is that we can properly fill the weight pockets and air seal the windows in place. I think the rest of the post might help someone so I’m leaving it up but updated the drawing. If you have any feedback on the drawing or other ideas I should put to work, I’m all ears. thanks!

——-

Seeking advice please. We’re in Zone 4. The snap shot of this is that we are residing and plan to remove coil window and door trim and replace it with traditional profiles. We are particularly concerned about water infiltration in the gap between our insert windows and the old window frames. It seems that the coil was smartly installed and served to shed water well for a few decades. A drawing of the proposed assembly and mock up are attached.

Apologies for the lengthy post that follows:

We’re about to start the residing our 1926 home, removing vinyl siding, ¾” EPS, and ½” cedar beveled siding. As part of this, we’re adding blown-in dense-pack insulation and continuous exterior insulation (CIE). This gives us an opportunity to rethink how our circa-1980s insert replacement windows are flashed and trimmed.

Existing Window Installation Details

The double-pane vinyl insert windows were installed from the inside, up against the blind stop.

Parting stops were removed, but the windows were sized to allow the weight pulleys to remain intact, leaving a ¼” gap all around each window.

Interior:

The windows sit against the stool, and the original interior trim was reinstalled against the window on the other three sides.

Exterior:

A 4” wide aluminum flashing strip was nailed to the middle of the sill, supported at the outer edge by a lath strip to maintain a 7-degree slope. The insert was seated over the inner edge of this sill flashing and rests against the blind stop.

Caulk is applied to the joint where the window meets the sill flashing.

Additional coil stock creates a faux sill, seals the casings, and the head sill.

There is no backer rod or spray foam between the original frame and insert windows.

Our Goals:

1. Replace the coil trim with traditional trim profiles and new lap siding.

2. Ensure proper flashing and water management without removing or reseating the windows.

3. Eventually build traditional storm windows to improve U-values and enhance the appearance of the existing vinyl inserts.

Despite extensive research, we haven’t found a clear approach to addressing our situation. It seems that most best practices involve removing and reinstalling the windows, which we are trying to avoid.

Proposed Solution:

We’ve developed a possible approach (see attached plan view), but we’re missing key flashing details and hope to refine our plan.

Wall Assembly (Inside to Out):

· ~1” Original plaster and lath

· Owens Corning blown-in insulation in 2×4 stud walls (16” O.C.)

· 1” Original tongue & groove sheathing

· Tyvek DrainWrap (StuccoWrap equivalent)

· Dupont 1” XPS, nailed 24” O.C. both horizontally and vertically

· 1”x4” furring, fastened and embedded per LP SmartSide specs

· 3/8” x 8” LP SmartSide lap siding, nailed to furring per LP specs

· Cor-A-Vent SV-5 at the water table and gables

· Rodent and pest screen

Z-flashing inserted behind the sheathing and taped

Window Flashing & Trim Plan:

· Leave existing casings and sills in place.

· Use flashing tape to create a monolithic seal back to the sheathing.

· Pad out the trim with 1” XPS and TruExterior 5/4 trim to match the siding profile.

· Install aluminum head and sill flashing.

· Apply house wrap, overlapping the tape joints and flashing shingle-style.

Biggest Concern: Wind-Driven Rain

We are particularly concerned about water infiltration in the gap between the insert window and the old window frame. Our current plan is to:

· Replace the blind stop with a 5/8” x 3” wide trim board, caulked to the face of the vinyl window.

· However, this feels like a weak link—we’re not sure if this is the best way to protect against wind-driven rain.

Seeking Advice

How would you properly flash and trim these insert windows? Are there better ways to manage water and air sealing for these types of inserts without removing the windows?

Thanks in advance for any guidance!

Replies

Since you're not removing or reseating the windows, consider inserting a backer rod into the gap between the window insert and the old frame before sealing with caulk. The backer rod will allow you to use less caulk, create a more controlled seal, and help prevent water from accumulating in the gap.