Input/criticism re home-built “I-rafter”

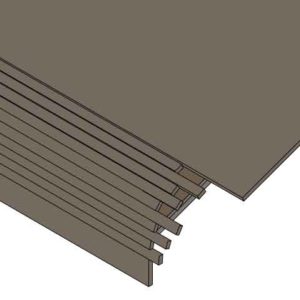

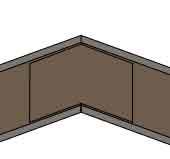

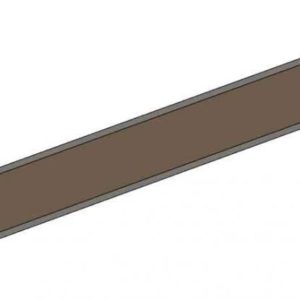

I consider myself a decent cabinet maker, and fair carpenter. I’m moving to a county that has no building permit requirement for a home, oh happy day!! Thus, one can get creative. I’ve designed an “I-rafter” and I’m hoping people with more building knowledge than I will comment, criticize, add ideas, etc. The structure I have in mind will be a 12′ x 40′ shop/design studio. I want a rustic look, with shingled sides, and I thought a rolled-edge roof would look nice. I’ll be working by myself, so I thought the light weight of these things would be nice. I have the notion I’ll do a hip roof, though I’ve never done one before, and am a little concerned about doing the corners with comp shingles. The rafters would be 8′ L, 9″ W. Edges would be true 1.5 x 1, ripped from 2x’s. web would be 1/2″ OSB, as would joining plate, which I would attach w/ PU glue and staples. Is the whole idea crazy? Should I just use 2×10’s? Or is shingling going to be too difficult?

Replies

No way.

Building your own structural materials is nuts. Usning them in the manner you're talking about using them is nuts.

Sorry to be hard on you, but..................You asked.

A coupla more responses like yours, and I'll give up on the home-made I-rafters. Maybe. Gut level, I'm pretty sure they'd be strong enough, especially on a small structure.On the other hand, what about the rolled edge, using 2x's? Shingling problems?

I've been thinking about BossHog's comment: "Building your own structural materials is nuts."Since when do can-do Americans assume that they don't have the brains to do what the pocket-protector guys do? I once was given the assignment of building a conference table 8' wide, 24' long, with a clear span in the middle of about 18'. I called an engineer friend about what would carry the span. He scratched his head and said: "I just do houses, man." My partner and I went to the local steel yard, dragged a small i-beam up on some concrete blocks 18' apart, and stood in the middle and bounced. It was good, and for good measure we used 2.Anyone with a good sense of materials can figure things out. No need to get all lawyered-out about everything.

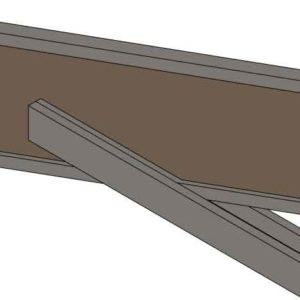

Here's pretty much the way I remember doing the scissor trusses, out of 2x4s. I thought the little toe-nailed in blocks were prolly overkill, but... And on these, I added the rolled edge. I'm wondering about foregoing the hip roof. But hip roofs are mighty purty, ain't they?

Hey, it's an experiment, right? So why not take it one step at a time and confirm that your concept will work?

First step is, how are you going to make the top piece of the I-beam roll over the radius? And how are you going to make it adhere to the web? Once you've got that solved, the rest should work OK.

The asphalt shingles will need some silicone chalk to hold each tab down, of those shingles which are near or past vertical. If, before nailing the shingles you first lay them in the sun on a similarly curved surface, they'll take that shape and be easier to apply correctly.

Best wishes, take pictures...post later.

I was planning to kerf the flanges where they go around the curve. They would also be dadoed 1/2" deep, in center, and glued to the webs w/ PU.Thanks for the good ideas on shingles. I'm mainly concerned with the corners. I've laid comp shingles plenty of times, but always on "normal" roofs.

I was planning to kerf the flanges where they go around the curve. They would also be dadoed 1/2" deep, in center, and glued to the webs w/ PU.

That's the usual method and it should work OK. Might need some trial and error so I'd work on that prior to getting the project underway.

Thanks for the good ideas on shingles. I'm mainly concerned with the corners. I've laid comp shingles plenty of times, but always on "normal" roofs.

Ah yes. Rolling over the hips. I'd try shortening those from a full tab, to half a tab, by simply cutting the bottom half of the tab off. So they'll roll around there without getting too misshapen. They'll probably still need a couple of exposed nails, along with the silicon. Or you could cut them even smaller, like your plan for the sheathing.

it might have been nice to include the details on post no 5 in the first post.

there is no doubt in my mind that you as a careful carpenter can make a superior I - joist than the factory does, but the time and money you will spend to do this will probably not be cost effective.

i was told once by an engineer about my idea to build my own gussets to connect I joists to make a gambrel roof that a lot of the strength of the design comes from the quality of the fit and assembly, the numbers could easily show it to work given a certain level of quality, but who is to say that level was achieved? The engineer certainly didn't want to stamp it as good based on my drawing, when he had never met me or seen my work.

if you have no inspection go for it, but i think you will come out money ahead using readily available pieces and parts, and just finding innovative ways to join them together.

Edited 4/20/2007 8:46 pm ET by segundo

Even with no building code enforcement, there's still the issue of liability. You're taking permanent responsibility for both engineering and fabrication here.

-- J.S.

Yep, and in my own house. I designed/built some scissor trusses for place I built on the Oregon coast. It has weathered storms with winds to 80-90MPH. I'm not an engineer, but think I have a fair grasp of reality.

nesika41,

You must not be planning to build in Ore. if you are moving to a county without permits.

(unless you know something I don't , in which case is there more land available in that county ;-) )

Funny you should say that. I don't think there is a county in OR (where I now live) NOT requiring a building permit. But I'm moving to western Kentucky, home of 2 gorgeous, gigantic lakes, and at least 2 of the counties there don't require permits--outside city limits: Trigg and Lyon.http://www.explorekentuckylake.com/To all who question my engineered "I-rafter": yep, I'm frequently guilty of reinventing the wheel, or worse. At a cabinet shop I used to co-own, I would design an elaborate jig for something, and then my shop foreman, Kenny, would show me a far, far simpler way of accomplishing the same task.My reasoning on the 9" wide I-rafter was: I could blow in cels afterward, for really good insulation. (Let's not get started about ventilation!)

I'm glad to see an original idea show up, any time. I'll bet you'll enjoy this project a great deal, both during the build and while living/working inside it. I appreciate your willingness to share your concept here. And I wonder why others feel compelled to question your knowledge/intelligence when all they have to suggest are the most conventional solutions.

Nothing wrong with re-inventing the wheel, if only because you'll learn a great deal while trying.

How is it diofferent than 2x8 rafter with collar ties?

"Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

I don't think it is different from 2x8-10's with collar ties, except for weight and cost. Truth to tell, I prolly ought to use 2x's.

Since they are only 9' long, why not fab them out of dimensional lumber, LVL or PSL. Use 2x materila for the decking and you can have three maybe four feet of space between rafters. If it is only 12' wide, I think it is very doable and I encourage the creativity. I think solid lumber is a better bet than I joist, then you can make a real solid connection at the ridge and cut a traditional birdsmouth at the wall. Maybe instead of a collar tie at the bottom, put in a steel cable.

I don't think the rolled edge is problem, probably just need to shorten your shingle exposure.

Best of luck

Bruce

Edited 4/19/2007 7:28 pm by Hiker

Don't get discouraged. A few years back in the magazine one guy wrote an article on house he built with homemade box beams. If memory serves me correctly he used ripped up sheets of plywood and/or mdf.

I think I would discuss spesifics with an engineer who knows his way around a calculator!

A county without requiring permits is not necessarily a good thing, especially if you ever decide to sell.

Have a good day

Cliffy

After looking over two buildings sold at Home Depot (Tuff Shed) and at Lowe's, their gambrel barn, two story models are much less engineered... They are 16'X24'.

The Tuff Shed model uses 2X10's on 16" centers for second story floor joists, and are just nailed to the top plate... No standard 2"X end band on the second story joists, they just used the LP siding to tie all of them together and Sturdi-Floor ply decking. The Lowe's model uses a full size 2X10 on each end of the second story joists; each joist is nailed through the end band on both sides of the building and OSB decking. Lowe's rafter/truss system seems stronger and has a tie going across the ceiling and in between the OSB gussets used to reinforce the angle cut rafter/truss...

If you use a commercial adhesive and screws on the I-beam construction, it would seem your I-beam design would offer much more strength than the commercially sold buildings... By the way, if you live in Texas, a 16'X32' gambrel roof Tuff Shed, with a slab foundation, two dormers, 6 windows, one steel door, and an 8'X32' porch will open your eyes... If built in a 30-mile radius building zone, with bare studs inside, no plumbing, and no electrical, it will cost you about $30,000.

Keep us posted with progress and pics, please.

Bill

a commercial adhesive?????Would that be one that allows creep or one that doesn't?with screws?Would that be structural screws or sheetrock screws?

What size

Why screws and not lag bolts or nails?

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Piffin & Nesika,

I'm retired, so time is important, but not like the Rat-Race clock used to be. The reason for my I-beam construction is to use lumber that is structurally sound but sold for pennies on the dollar at the big-box stores.

Let me see if I can show you my thinking....

a commercial adhesive?????

I'm using the exterior adhesive sold for wooden decks.

Would that be one that allows creep or one that doesn't?

with screws?

It shouldn't allow creep, but the screws and glue will make the 2X6 bonded on both edges to the flat face of a 2X4, and should become as one truss beam for a gambrel style roof. Their roof angles are cut and reinforced with plywood gussets, and are nailed to a 2X6 sill plate attached to the Sturdi-floor plywood decking on the 2nd story.

Would that be structural screws or sheetrock screws?

I bought a 25 lb. pail of galv. deck screws to use with the glue.

What size

3-1/2" long deck screws.

Why screws and not lag bolts or nails?

Ringed nails are expensive, and even though "Tractor Supply" sell lag bolts for $1.88 a pound, they are too costly. The bucket of deck screws should go a long way.

I'm able to buy lumber for pennies on the dollar. To use the culled lumber that can be cut to length of a almost perfect quality board, I'm first using a pressure treated 2X4 bolted and sealed to the foundation slab. Another 2X4 is stood on edge and screwed to the outside of the baseplate as is a second one on the inside, making a "U" channel. The width of the base plate is now wider than a 2X6 and measures 6" wide.

The 2X4 framing studs are I-beam style too, but with a flat 2X4 nailed to each edge of the stud and cut shorter than the stud to allow for the height of the "U" plate on the bottom and a matching one at the top of the framed wall.

I'm building a 16'X32' cabin-style storage building in the back yard. Tuff Shed wants $30,000 to come build one with bare stud walls and nothing finished out. Using the culled lumber that is pulled straight with the I-beam method, I can build it on a concrete slab, wire it, insulate the lower floor, and finish out all the walls for less than $7,000.

So this I-beam method should be "hell for stout", yet economical and stable. Here's Tuff Shed's data sheet:

Bill

Dimensional lumber with radiused ends and built up layers of bendable sheathing would do the same thing, be much, much faster, and cheaper.

Hips are doable - you'll be weaving cap shingles over the mini ridge.

Making your own I-joists strikes me as crazy and labor intensive, and for a 12' span, I'd not worry about the weight of the lumber.

The "labor intensive" part opf other comments is worth noting.

I am an 'enginear' an' partly agree with Boss H (who I hardly ever disagree with).

See, if I'da thought to do somthin' like that, I'da just done it knowing what I did would be good and only told here afterwards<G> - if you need to ask, you need to read some more structures books. My favorite from long ago is Timeshenko and Young, "elements of strength of materials". Once you fathom the material there, I'd say go for it.

Again on 'labor intensive' - designed a 36 ft long built up beam for my brother's house. Out of pocket material cost was maybe 20% of a big glue lam. Brother said for all the time he spent building it he'da bought a glue lam if he had the choice to make again, or have Boss do a truss for him if weh'e known him then.

I don't like to be critical of somebody trying to do something outside the box if it is doable.In this case, the problem is thqat he will spend three times as much labour to get a questionable result.

But if that is his goal in life, who am I to bark at him?He did ask for critique though.What I see as the two weak points in his design are the kerfs in the curved toop member and the joint at the ridge.That ridge joints should be steel probably and the kerfs will weaken that member where strength is required.From a roofing POV, the asphalt shingles will lay right down on a hot day, but that rolled edge will be a spot where winds accelerate and try harder to tear the shingles off.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Rather than go to the time and trouble of building a structurally questionable I joist, I would use wood rafters (2x4s would be enough for a 6 foot span) and have the curved section in the overhang. The end of the rafter would begin the curve and the rest would be cut with a piece of scrap and fastened on the side with plywood cut with the entire curve.

This would cost less, take less time and be structurally sound. Your only remaining problem is supporting the ridge. You also might have to raise the height of the walls to accomodate the fact that the curve is below the top of the wall rather than above. Good luck and send pictures of the finished product, whatever your decision. It looks like fun.

Go for it.

Test first. Build three, set 'em on blocks, tack some sheathing on with screws and set a pallet of shingles up near the ridge, then jump up and down on the other side.

Get somebody with a cell phone to observe.

I would use a 1x3 cleats on both sides of all web joints.

SamT

There are three kinds of people: Predaters, Prey, and Paladins. The really strange thing is that Prey feels safer from Predators by disarming Paladins.

"Get somebody with a cell phone to observe."

Better yet, someone with a video camera. That way he could send it in to "America's Funniest Home Videos".

(-:

Q: Why don't roosters have hands?

A: Because chickens don't have boobs.

just curious, and not trying to spark an arguement, but do you think an engineered design is the only way to accomplish this task, without sacraficing quality and srtuctural integrity.

My reasoning for saying it was a bad idea was as follows:1. The OP has no idea how to design or build an I-joist. i.e. what size the flanges need to be, how thick the plywood web should be, how much to taper the groove in the flanges, what kind of glue to use, etc. 2. I-joists as rafters require a structural ridge beam. The OP probably doesn't know that, since it wasn't shown in his drawings. 3. If he doesn't know that, then he likely doesn't know other things about framing with I-joists, such as when web stiffeners are needed, when a birdsmouth is allowed, etc. 4. I think it's wrong to make a half-hearted attempt at anything structural. If something like homemade I-joists give someone trouble down the road, they can be expensive and difficult to fix. I'm not trying to knock the OP here. I just think it's a bad idea..I will admit that I initially missed the fact that this structure is apparently only 6' wide. On something that small it may not be all that big of a deal in this case. But in general, I still think it's a bad idea.

I would rather live a short life of glory than a long one of obscurity [Alexander the Great]

What is OP?

OP= Original Poster

Op means "Original Poster".In this case that's obviously you..BTW - I serve 2 purposes around here - I *AM* a clown to some degree, but I'm also dead serious (and pretty conservative) when it comes to structural issues. I don't take life too seriously, but I do take my work seriously.

As to the difference between the Unabomber and Colin Powell, allow me to quote from that never-ending source of wisdom: Megadeth lyrics. [Robert Harley]

1. If people had to know beforehand "how to build" such and such, we'd never have progress. I showed you the scissor truss I designed/built, which has withstood huge Oregon storms. I don't know that I'll use this design, but I'm confident it would withstand a reasonable load. And you have no basis for saying what I do or don't have the "idea to design". 2.What is "required" is what works. All you're doing is sticking to the past. If we were stuck with your gene pool, we'd still be living in caves, because, obviously, nobody KNEW how to build a house. How DARE someone presume to build something that hadn't been built before, and/or without an engineering degree!3.You have no idea what I know and don't know. You're just lashing out at anything new.4.What's your proof that I do ANYTHING "half-hearted"?5.You are exactly trying to knock me. Be man enough to admit it.6. If you want to admit something, admit that you still don't know how wide the structure is.Blowhards like you are the bane of every forum. There are lots of folks to pitch in with advice, even friendly criticism, then there are the resident clowns and bullies.

Re my post on testing. Please change the procedure to you lying underneath and no witness with a cell phone, while you drop a pallet of bricks on top.

Just to be clear, I am knocking you, your intelligence, your knowledge, and your sense of curtesy.

SamT

Future inmate #2849276

There are three kinds of people: Predaters, Prey, and Paladins. The really strange thing is that Prey feels safer from Predators by disarming Paladins.

Edited 4/20/2007 10:36 am by SamT

I've been nothing but polite andreasonable towards you. There's no reason you you to talk to me that way.

Your village just called. They're missing their idiot.

"I've been nothing but polite andreasonable towards you."And as Nixon once said: "I am not a crook!"

And as Mike Smith once said:"BITE ME".You asked for input and you got reasonable input. If you can't handle it, log off BT and go cry to your mommy.

What do you get when you cross a computer with a prostitute:

A f___ing know-it-all

Nesika41, you are way out of line here (and in your later posts). BossHog is one of the most knowledgeable people here on the widest range of subjects relating to building. He's not a clown, although as with any discussion there is sometimes some light ribbing (his comment that building your own structural members was "nuts")You asked for input and criticism, which he gave (both briefly and in much more detail), in a polite and informative way, with just a touch of levity. You responded with attacks to constructive criticism. If that's your style, maybe you should get into the Woodshed and limit yourself to POLI-JIVE threads.Eric

If you and others feel that bosshog is an asset here, you doubtless know more, as regulars, than I do. However, I ask you to more thoroughly review the situation. His first comment was "nuts". I responded with self-deprecating humor. His second comment was to the effect I'd end up on America's Funniest Videos. I didn't respond. His third, lengthy comment, implied nothing but ignorance, sloppines, and half-heartedness on my part.Yes, then I lashed out. His next comment was that he had only been courteous. If you think his comments were "courteous," then I have entered an alternate universe.If I have offended anyone here but bosshog, I apologize. I stick by my characterization of him (INSOFAR AS HIS DEALING WITH ME ARE CONCERNED). His treatment of me was hog-in-a-china-shop Now, I will take the good suggestions I received and head off for the doghouse.

When I saw your original post, I didn't respond as I thought anyone seeking to do what you want to do will probably ignore anything but a "go for it" response. It looks like I was right.

As has already been demonstrated, BH and the other regulars on this forum can certainly defend themselves, but your last couple postings including the one I am replying to are pure horsedung. If you ask an open-ended question, then just take all the feedback and consider it worth what you paid.

BTW, IMHO you are nuts to be wasting time reinventing readily available structural components for your project, not because you have some great new idea - you don't. Try out your ideas on a tool shed or scale model.

FWIW, Interesting "bane of every forum" comment since you clearly don't even know common forum acronyms even after lurking here for a good 5 years.

I see your other posting 5 years ago also got you a "lighten up" response. Nice.

I see your other posting 5 years ago also got you a "lighten up" response. Nice.

Got a link? Or thread number?"Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

aaaaah, just drop it. . .SamT

Praise the Corporation, for the Corporations' highest concern is the well being of the public.

I agree we should all drop this... and Nesika, but here's the thread I referenced from 2002. Search function actually works when I don't care what I find. ;-)

http://forums.taunton.com/tp-breaktime/messages?msg=21452.4

WOW, if attitude will get you anywhere, you will end up all the way to the moon, which is fittings since this idea of yours is half luny.Get rid of the attitude and you might learn something."And you have no basis for saying what I do or don't have the "idea to design"."

The drawings yopu presented indicate a great lack of knowledge which hints to me - not a pro truss guy - that you don't have any idea what you are doing. Especially the lack of detailing"If we were stuck with your gene pool..."

You wanna be insulting eh?

Well, try this one - If we were stuck with your gene pool, we might all die from structures caving in on us and never get a chance to reproduce or do so only by the light of the moon.

;)"You have no idea what I know and don't know"

your drawings and approach are indicative enough to give some idea"What's your proof that I do ANYTHING "half-hearted"?"

The drawings lack detailing and specifics for one thing."Blowhards like you are the bane of every forum."

pot calls the kettle black....

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

i don't disagree with you that it's a bad idea. i think it's too much work myself. i would frame with conventional framing and try to add a scabbed radius of some sort, as schelling mentioned earlier. i'm not sure of the benefit to making your own trusses. i was just wondering your opinion.

Can we try to just all get along......"i'm not sure of the benefit to making your own trusses."I'm not sure of the viability of my "I-rafter" either. But I AM very confident of my scissor truss, posted earlier. And here are some of my reasons for DIYing them:1. Because it's easy to do with CAD, I dickered with the angle of the bottom chord (if that's the right term), until the length of each side was 6'. or exactly 1 1/2 sheets of DW, saving time/materials when DWing.2. Just like anything else you build with your own hands, it's fun and rewarding. Saving money is an added attraction. (If, like me, you're retired, the "time is money" phrase takes on new meaning.

I'm retired too.

I didn't know it was a license to be a jerk.

You asked for opinions and you got them.

Building TJIs to save a buck is foolish, but go for it.

Joe H

the length of each side was 6'.

Better to make it 6'-0 1/2""Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

"Better to make it 6'-0 1/2"Huh?

Ok, at the risk of sounding condesending and possibly insulting your intelligence ...

Supposr that your 1-1/2 pieces of sheetrock are exactly 6 ft wide. If you build the walls exactly 6 ft apart you are going to have the edges of the sheetrock in full contact with the wall studs and top plate, which will make installation ... not hard ... but annoying maybe. But if you make the walls an extra half inch wider, then you have a little wiggle room to get the rock in place. Since the ceiling rock is installed first, the wall rock will cover a gap up to 1/2" on each side, and the joint tape will easily cover a 1/4" gap between the sheets. So really you could build the walls 6'-1 1/4" apart for your exactly-cut 1-1/2 pieces of rock.

Or, Mr Efficiency, go ahead and build the walls at 6'-0" and then you get to waste a bit of rock when you cut the second sheet to fit.

But let's take it a bit further. Suppose you build so the sheetrock, the easiest thing to dimensionally adjust, works out right. Have you worked out how many studs it wil take in the end walls? What about the number of full pieces of exterior sheathing and siding, and roof deck sheathing?"Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

Back in 2002, this guy insulted to only reply he got by implying that there was no reasonable intelligence in it, then later, he seemed curious why nobody else had replied!So acting condescending and insulting one's intelligence is not something he is unfamiliar with. so far he's about 0-26-2

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Great, Now you want to teach him the realities of hanging sheetrock?;)

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

"I dickered with the angle of the bottom chord (if that's the right term), until the length of each side was 6'. or exactly 1 1/2 sheets of DW,"This is getting laughable!The primary approach to designing structural members should be to design to the load it will carry, not to making it fit the sheetrock!

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

This is getting laughable!The primary approach to designing structural members should be to design to the load it will carry, not to making it fit the sheetrock!"You moron, whether the angle is 19 degrees or 21 degrees isn't going to affect strength. And, good gosh, pile on all you want, but I was/am quite aware of the 1/2" here and there.You and Fast Eddie can continue entertaining one another (I might say it looks like a circle jerk), but it'll be for your own entertainment; I'm out of here.

Yeah, yeah, yeah..Everybody's a moron but you!

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

I deleted my comment to you but didnt want to delete the post so that you dont get the "you have a unread message"

Edited 4/21/2007 10:46 am ET by DougU

Thanks, but we should all disrecall this whole thread anyways. I still have a shadow calling me back to the immus thread i'll have to deal with someday.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

I still have a shadow calling me back to the immus thread i'll have to deal with someday

I assume this is something in the tavern?

My post to you was not all that well thought out so I deleted it for the sake of a misunderstanding.

Doug

whether the angle is 19 degrees or 21 degrees isn't going to affect strength

well, it does as you'd know if you'd read the book..... Please dont call people morons and then make a structurally false statement.

The fine citizens of Oregon (and the rest of them too) will be breathing a sigh of relief to see this guy move.how long do you suppose he'll last in Kentucky?Guys with this sort of attitude here last about 1-1/2 to 3-1/2 years. They move in proclaiming what a wonderful place it is and how they will spend the rest of their lives here, then move away explaining how terrible the place has become in the meanwhile...

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

>>>>>>>>>how long do you suppose he'll last in Kentucky?Glad he's moving to Western Kentucky instead of my little slice of heaven.http://grantlogan.net/

Those of you who are regulars here: is bosshog merely the resident clown, or does he sometimes have something of value to say?

I think I can speak for most of the regulars here when I say that Boss truly knows his stuff about trusses, and he is conservative or cautious in his designs and the advice he offers. He can come across a bit harsh at times, and has no tolerance for smart alecs. But he does have a good sense of humor.

Some of your very recent posts seem to be a bit antagonistic toward him. I suggest you drop that attitude. You don't have to take his advice, none of us really care how you build your shed. But if you want professional advice on truses, and he offers it, don't tell him he's wrong.

"Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

FastEddie, and Eric Harper - (And SamT)I appreciate the kind words.

Growing old is like being penalized for a crime you didn't commit [Anthony Powell]

No problem. Be sure to send cash this time, no more hot checks. But hot chicks are ok."Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

If I had hot chicks here, do you really think I'd share them with YOU ???(-:

I have the best lover in the world.

I can only hope that she and DW don't run into each other.

Boss is a proffesional truss designer.So he comes by his strong opinions with some good background.Remember - you DID ask for criticisms!

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

There is some truth in the comment that making your own structural members is nuts. Let me explain why:

For the most part, specific structural pieces were designed to replace traditional post & beam methods. The goal was two-fold: reduce material, and allow less skilled labor do the job.

Only later did we realize that we could also use engineering to make pieces in sizes that would not have been possible with 'solid' lumber.

The folks who make these things have two advantages that you lack: First, the education to do the math, and see if a design might work. Just as important, they also have the facilities to test sample designs, and confirm their numbers.

My suggestion? Build it the "Japanese way." That is, make the roof first. Then, with the roof sitting safely on the ground, load it up. Sandbags, blocks, whatever- spread them around to simulate the weight of three layers of shingles, then jump around on the thing. See just how solid it really is. A collapse at this point is far less damaging than one three years later, during a blizzard.

Why do you believe an I-Joist would be a better structural solution? I assume you are aiming to reduce the squeaks, but i do not believe you can mimick a TJI. TJI's have two properties that are great. Long spans and noise control. In your case, Long span, no, squeak maybe, but I do not believe you can re-produce TJI's to see this benefit. This might be a make work project that yeilds little??? Couple I-joist facts. There are strict quality control measures enforced in the production of I-joist's and the moisture content of the top and bottom chords is less than what you have available at the local hardware store. In addition, they use a resorcinol adhesive that requires a far greater pressure to gain the full strength (100psi) than feasible by a handyman. A PL400 type adhesive is more for controlling squeaks than structural. Now saying that I know many carpenters who will dispute that statement having removed sheathing after gluing; however, from a structural standpoint it is too flexible.

If you do proceed, pay close attention to the nailing of the collar tie (critical to avoid kick at the base) and reinforce the ends of the I-joists because they do not have great shear capacity and stability is always a concern.

"Why do you believe an I-Joist would be a better structural solution?" I will confess that it all came up when I was pricing i-joists. I thought: I could make these myself for 1/3 the amount. I'm retired, so have plenty of time to waste.That said, as I implied several times earlier, I've about decided that my design is more trouble than it's worth.Keep in mind, though: we're talking about a 12' span, for goodness sake!! Or really, closer to 11', since walls will be 2x6's.

"I thought: I could make these myself for 1/3 the amount."That is a great insight to your thinking process.

based on limited information, you jump to conclude and assume that which is far from true. Even working for free, it will cost you more to build these than any other way.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Most people don't give rafter lengths. They give the horizontal distance between bearing points (span).

It appears you have a 6' span. 2x4s are sufficient for that.

---

One reason for hiring an engineer is that he knows how to make work easy.

GHR, "Span" for me means the distance between supports so : I have always used wall to wall as the "span" of the building. Wall to center (if using a ridge) as the span for a rafter. A pre-built truss uses wall to wall as the span is my understanding .

Are you sure you're free & clear to build as you wish? Even though your county does not have building permit process or building department to conduct inspections (usually based on a budget, small county budgets preclude the department & employees) I bet KY has a standard code on the state level that everyone is expected to build to even though it may not be inspected. Not following those codes (even though not enforced by the local govt) exposes you to significant liability issues if someone were to get hurt by your design.

It didn't take google long to find this http://www.lrc.ky.gov/krs/198B00/CHAPTER.HTM and I bet if someone were really serious about looking for it they'd find more.

Don't worry - you're OK

I built 20 16' I-joists for a workshop many years ago. I grooved 2x's then glued a 1/2" ply web into the grooves. After a lot of years, absolutely no problems. Just make sure the glue runs the full length of the I-beam and clamp everything together until dry.

and, by the way, I'm an engineer and I wasn't willing to pay $130 for the store bought I-joists when I could build one for less than $20